Gradient nano-coating used for thermal barrier coating anti-corrosion function and preparation method thereof

A technology of nano-coating and thermal barrier coating, which is applied in the field of gradient nano-coating and its preparation, can solve problems such as thermal expansion coefficient mismatch, peeling off of the outer anti-corrosion alumina coating, etc., to overcome the difference in thermal expansion coefficient, method Simple and easy to implement, the effect of uniform coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] YSZ / Al 2 o 3 The preparation method of the gradient nano-coating is realized through the following steps:

[0020] The first step: the monoclinic YSZ sol with a solid content of 2wt% and the Al with a solid content of 2wt% 2 o 3 Sol, respectively prepare YSZ-Al according to volume ratio of 3:1, 1:1 and 1:3 2 o 3 Mixed sol.

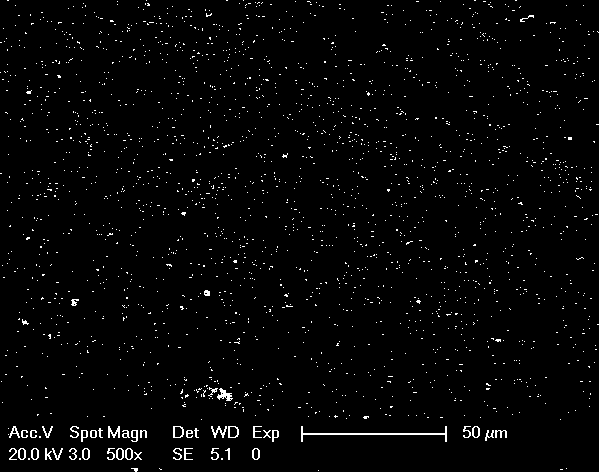

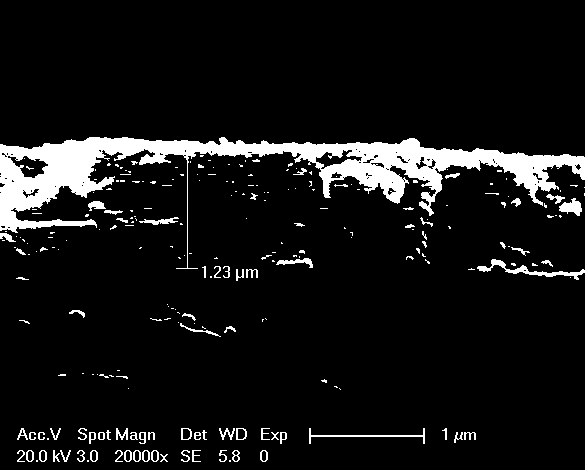

[0021] The second step: use a dipping machine to dip-coat the zirconia ceramic substrate sequentially with YSZ sol, YSZ-Al with a volume ratio of 3:1, 1:1 and 1:3 2 o 3 Mixed sols, and Al 2 o 3 Sol. The descending and ascending speeds are 20mm / min, the dipping time is 120s, and it is dried at 100°C. Each sol was dip-coated 5 times and calcined at 600°C for 2 hours. Prepared a gradient nano-coating structure with a total thickness of 1.23 μm and a particle size of 10-100 nm (see the SEM images of its surface and cross-section figure 1 ). according to figure 1 (2), the cross-sectional view of the coating shows that there is no obvious bo...

Embodiment 2

[0023] YSZ / Al 2 o 3 The preparation method of the gradient nano-coating is realized through the following steps:

[0024] The first step: the monoclinic YSZ sol with a solid content of 2wt% and the Al with a solid content of 2wt% 2 o 3 Sol, prepare YSZ-Al according to volume ratio of 9:1, 3:1, 3:2, 1:1, 2:3, 1:3 and 1:9 respectively 2 o 3 Mixed sol.

[0025] The second step: Use a dipping machine to dip the zirconia ceramic substrate into YSZ sol sequentially, the volume ratio is 9:1, 3:1, 3:2, 1:1, 2:3, 1:3 and 1:9 YSZ-Al 2 o 3 Mixed sols, and Al 2 o 3 Sol. The descending and ascending speeds are 20mm / min, the dipping time is 120s, and it is dried at 100°C. Each sol was dip-coated 5 times and calcined at 800°C for 2 hours. A gradient nano-coating structure with a total thickness of 5.0 μm and a particle size of 10-100 nm is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com