Phase change hardening stainless steel product and manufacturing method of phase change hardening stainless steel product

A technology of phase change hardening and manufacturing method, applied in the field of stainless steel, which can solve the problems of poor corrosion resistance, poor hardness, and large application limitations, and achieve the effects of good corrosion resistance, good ductility, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

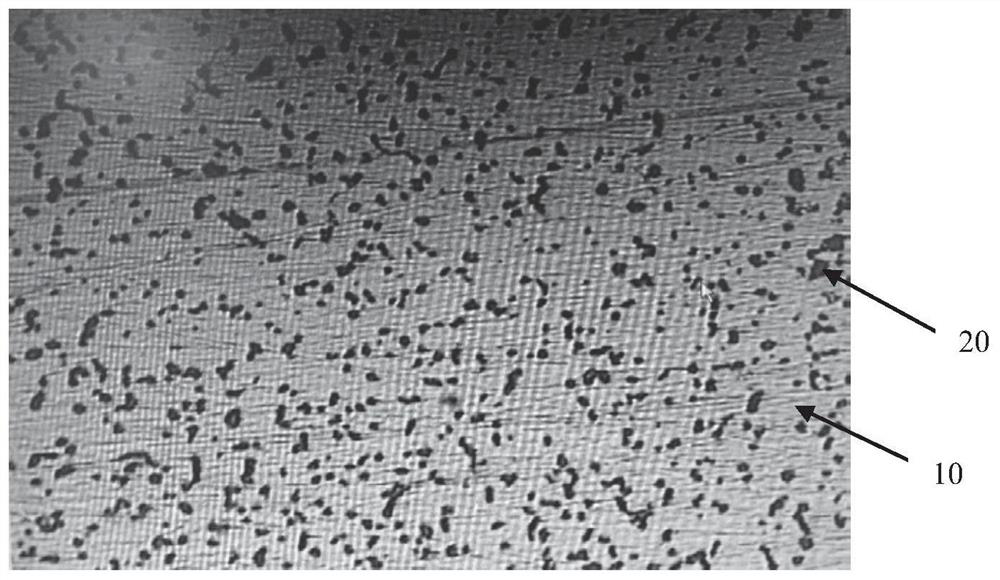

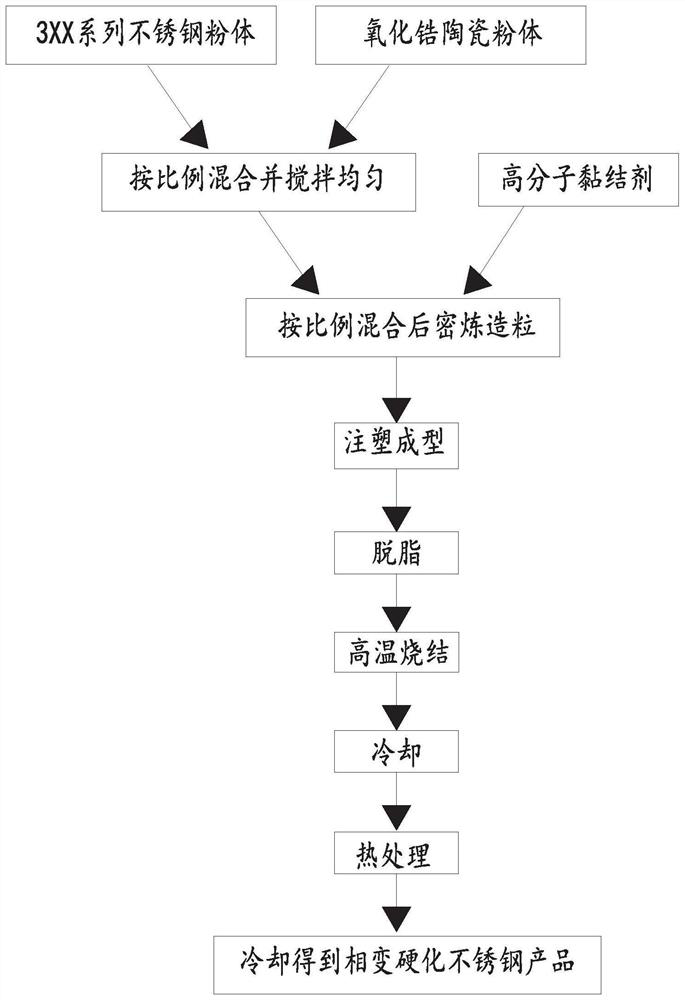

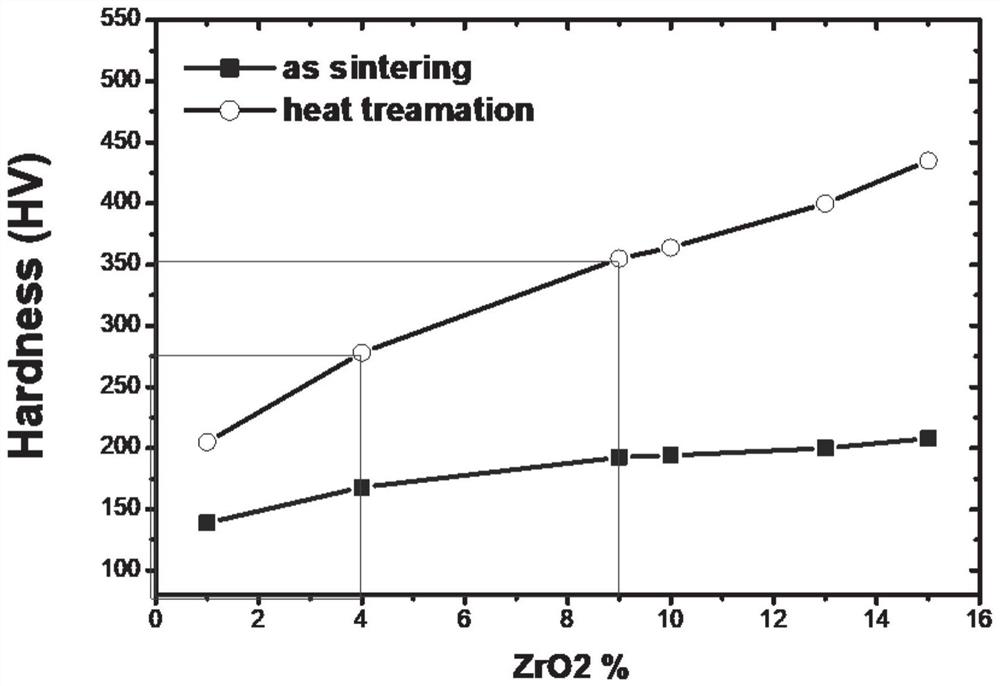

[0097] Evenly mix 304L stainless steel powder with a d90 of 20-25um and 1wt% superfine zirconia powder with a d90 of 1um, then mix it with a polymer binder in proportion, and then granulate it with a banbury mixer to make granules Feed the material, and then make the green embryo by injection molding, then carry out catalytic degreasing, and then carry out high-temperature sintering at 1360°C in the vacuum environment provided by the vacuum furnace, and obtain a density of 7.72g / cm after cooling 3 , the intermediate product with a hardness of HV139, and then heat the intermediate product to 1300°C in the vacuum environment provided by the vacuum furnace for heat treatment, and obtain a phase transformation hardened stainless steel product with a hardness of HV208 after cooling. This product has good corrosion resistance, ductility Good performance, non-magnetic, high hardness, high wear resistance, can be used in extreme environments.

Embodiment 2

[0099] Embodiment two is basically the same as embodiment one, the difference is that in embodiment two,

[0100] The proportion of ultra-fine zirconia powder is increased to 4wt%, and the density of the intermediate product made is 7.75g / cm 3 , the hardness is HV168, and the hardness of the final transformation hardened stainless steel product is HV275.

Embodiment 3

[0102] Embodiment 3 is basically the same as Embodiment 1, except that in Embodiment 3, the proportion of ultrafine zirconia powder is increased to 9wt%, and the density of the intermediate product made is 7.54g / cm 3 , the hardness is HV192, and the hardness of the final transformation hardened stainless steel product is HV353.

[0103] In this embodiment, in order to avoid the situation that it is difficult to process due to excessive hardness during the subsequent processing of phase transformation hardened stainless steel products, after the intermediate products are made, the shape and size of the intermediate products are processed according to the requirements. Heat treatment is carried out so that the shape and size of the final phase transformation hardened stainless steel product meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com