A sliding cross-linked network acrylate rubber seal and its preparation method

A rubber seal, acrylic technology, used in the field of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

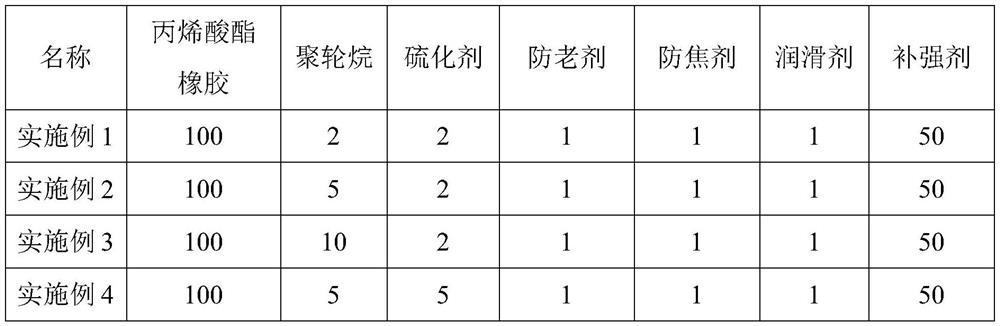

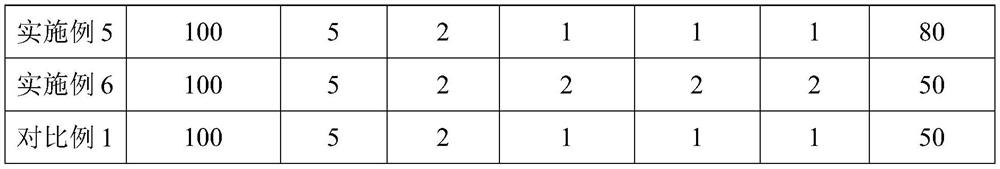

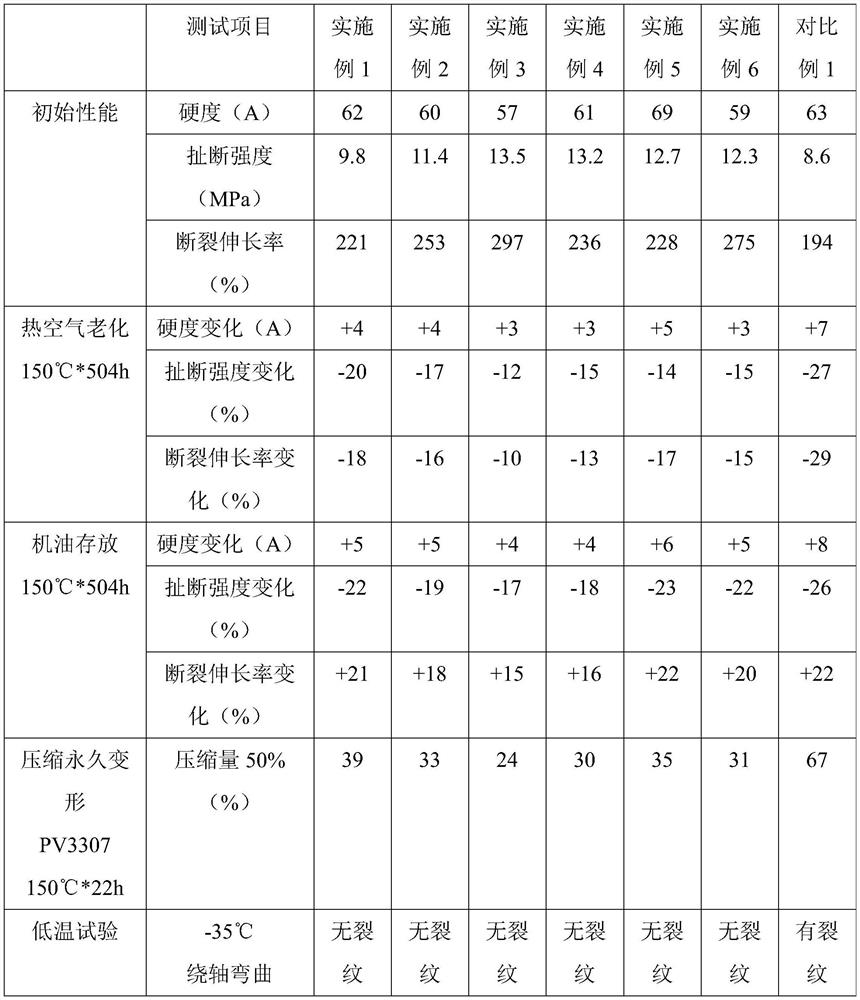

[0022] The raw material compositions of Examples 1-6 are shown in Table 1, and the amounts of each component in Table 1 refer to parts by mass.

[0023] The raw materials used in Table 1 are described as follows: Acrylate rubber is epoxy type. The linear molecule of the polyrotaxane is polymethyl methacrylate, the cyclic molecule is hydroxypropylated γ-cyclodextrin, and the end-capping group is a trityl group. The vulcanizing agent is trimethylbenzyl ammonium chloride. The anti-aging agent is 4020. The anti-scorch agent is N-cyclohexylthiotitanimide. Lubricants are fatty acids. The reinforcing agent is FEF carbon black.

[0024] Preparation steps: (1) Add the acrylate rubber, polyrotaxane, anti-aging agent, reinforcing agent, and lubricant in the formula in Table 1 to the internal mixer, and knead at 110°C for 10 minutes; (2) Add vulcanizing agent, anti-scorch (3) After the mixing is completed, put the rubber into a flat vulcanizing machine for two times of vulcanization....

Embodiment 7

[0036] The materials used, proportioning and preparation steps are the same as in Example 2, except that the linear molecule of the polyrotaxane is polyvinyl acetate, the cyclic molecule is hydroxypropylated γ-cyclodextrin, and the end-capping group is adamantine Alkyl groups.

Embodiment 8

[0038] The materials, proportions and preparation steps used are the same as in Example 2, except that the vulcanizing agent is polyethyleneimine, the lubricant is silicone oil, and the reinforcing agent is a composition of white carbon black and talcum powder (mass ratio 1:1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com