Anti-corrosion alloy and descaling method for derivatives of anti-corrosion alloy

A technology of corrosion-resistant alloys and derivatives, used in metal processing equipment, used abrasive treatment devices, manufacturing tools, etc., can solve problems such as high cost, poor conductivity, and complicated cleaning, and achieve low cost and good quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

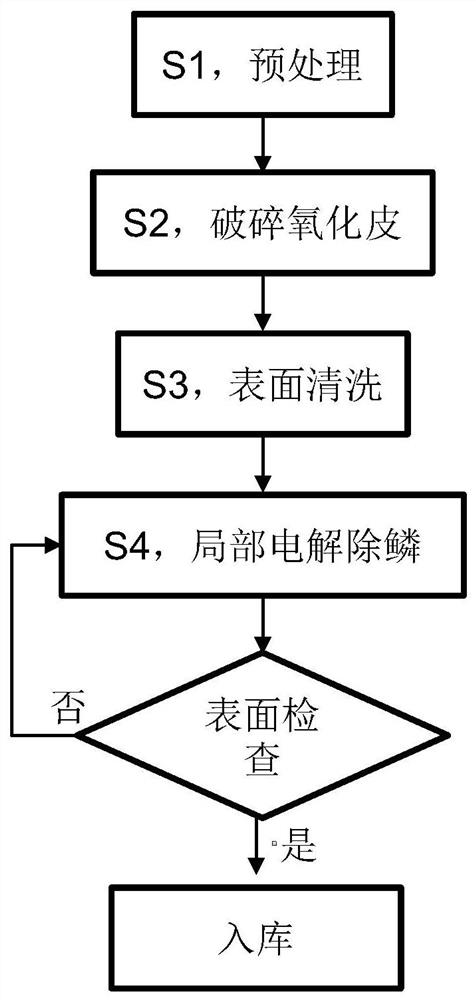

[0067] Corrosion-resistant alloy derivatives in Examples 1-6 are 304 / Q235 composite hot-rolled products, and water is used as the electrolyte during electrolysis, that is, the cation in the electrolyte is H + , the anion is OH - , descaling is carried out by the following steps:

[0068] S1, pretreatment, removing impurities on the surface of corrosion-resistant alloy derivatives;

[0069] S2, broken oxide skin, physical method to break the oxide skin on the surface of corrosion-resistant alloy derivatives; the physical method adopts jet impact method or shot blasting impact method;

[0070] S3, cleaning the surface, removing impurities on the surface of the corrosion-resistant alloy derivatives treated in step S2;

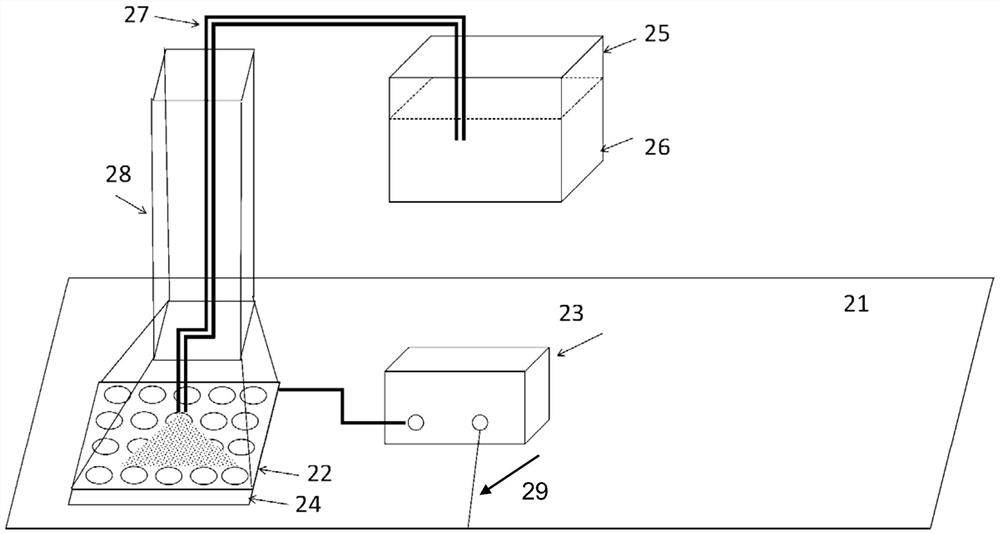

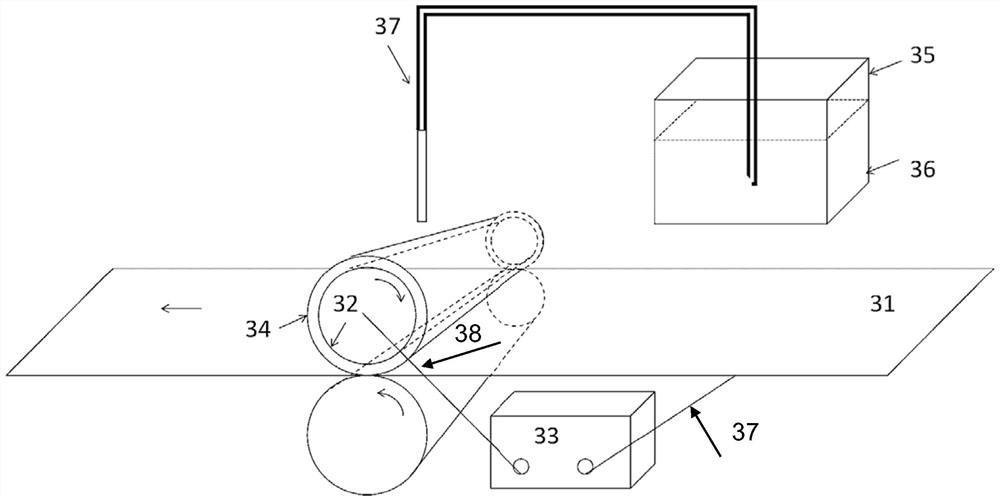

[0071] S4, local electrolytic descaling, using local electrolysis device to electrolytically descale the surface of corrosion-resistant alloy derivatives;

[0072] The specific process parameters in steps S1-S4 are shown in Table 1, wherein the local electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com