Nano-zinc oxide modified composite plate and preparation process thereof

A technology of nano-zinc oxide and nano-zinc oxide powder, which is applied in the field of materials, can solve problems such as poor surface finish, poor thermal stability, and poor tensile strength, and achieve the effects of good thermal stability, improved smoothness, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

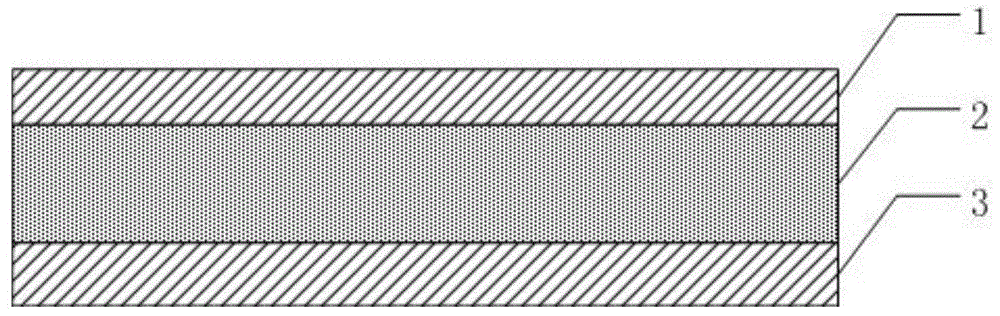

[0023] Such as figure 1 As shown, the nano-zinc oxide modified composite board of the present invention is composed of three layers, which are respectively PMMA layer 1, nano-zinc oxide modified layer 2 and PMMA layer 3 from top to bottom, wherein the nano-zinc oxide modified layer 2 Contains nano-zinc oxide and polyvinyl chloride, the mass ratio of nano-zinc oxide in polyvinyl chloride is 0.6% to 1%, nano-zinc oxide is uniformly dispersed in polyvinyl chloride, and the thickness of PMMA layer 1 and PMMA layer 3 is 0.45 ~0.55mm. Before modification, the tensile strength of the PVC sheet is 15Mpa, and the impact strength is 6kJ / m 2 , while the tensile strength of the nano-zinc oxide modified composite plate reaches 78MPa, and the impact strength is doubled to 13.6kJ / m 2 .

[0024] The nano-zinc oxide modified composite board of the present invention has the advantages of high smoothness, high thermal stability, aging resistance, good tensile performance and high impact stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com