Glass fiber reinforced polyethylene hollow-wall winding pipe and manufacturing method thereof

A technology of polyethylene and winding pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., which can solve the problems of increased pipe weight, poor hydraulic performance, and easy leakage, etc., to reduce production costs and enrich production method, the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

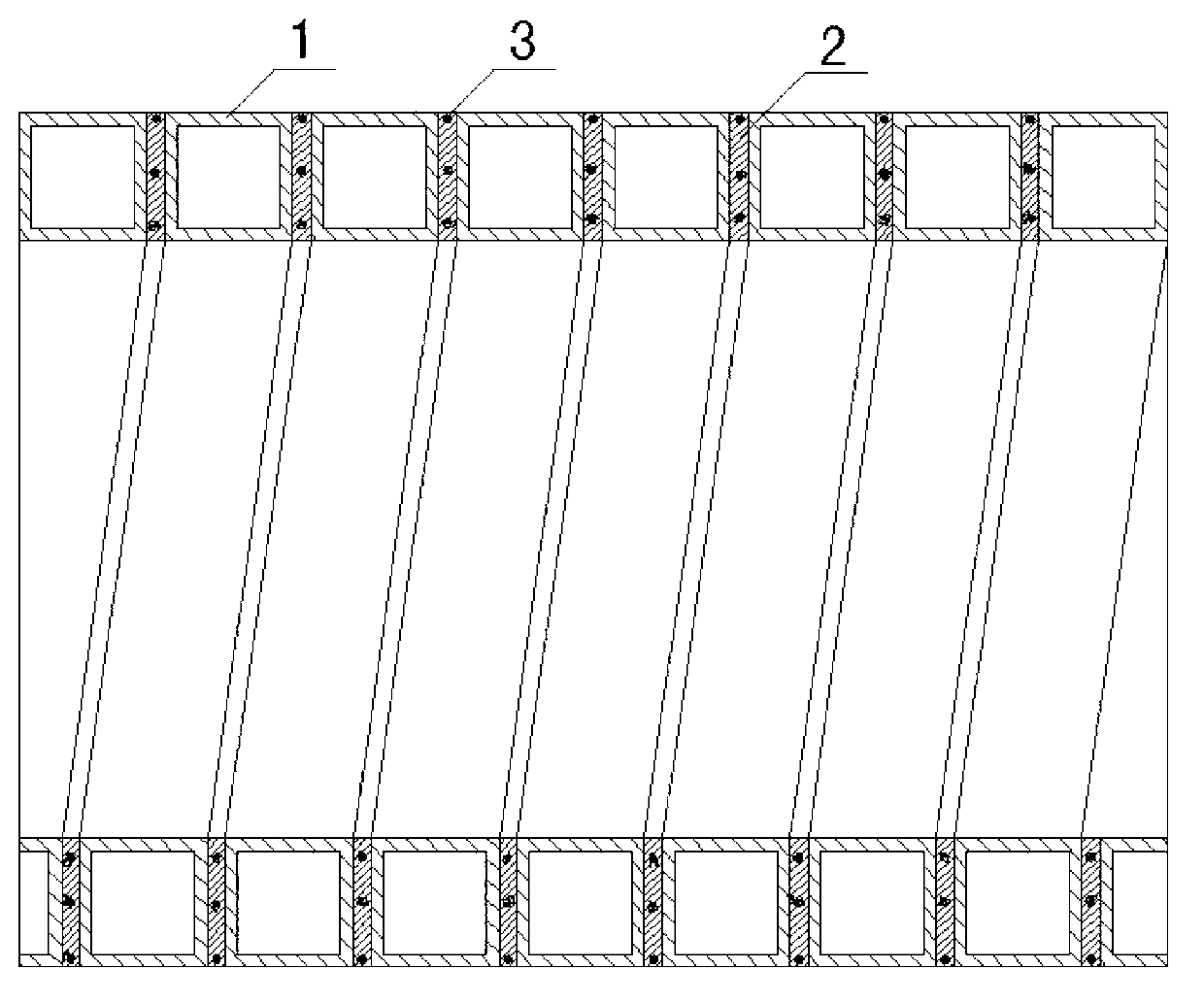

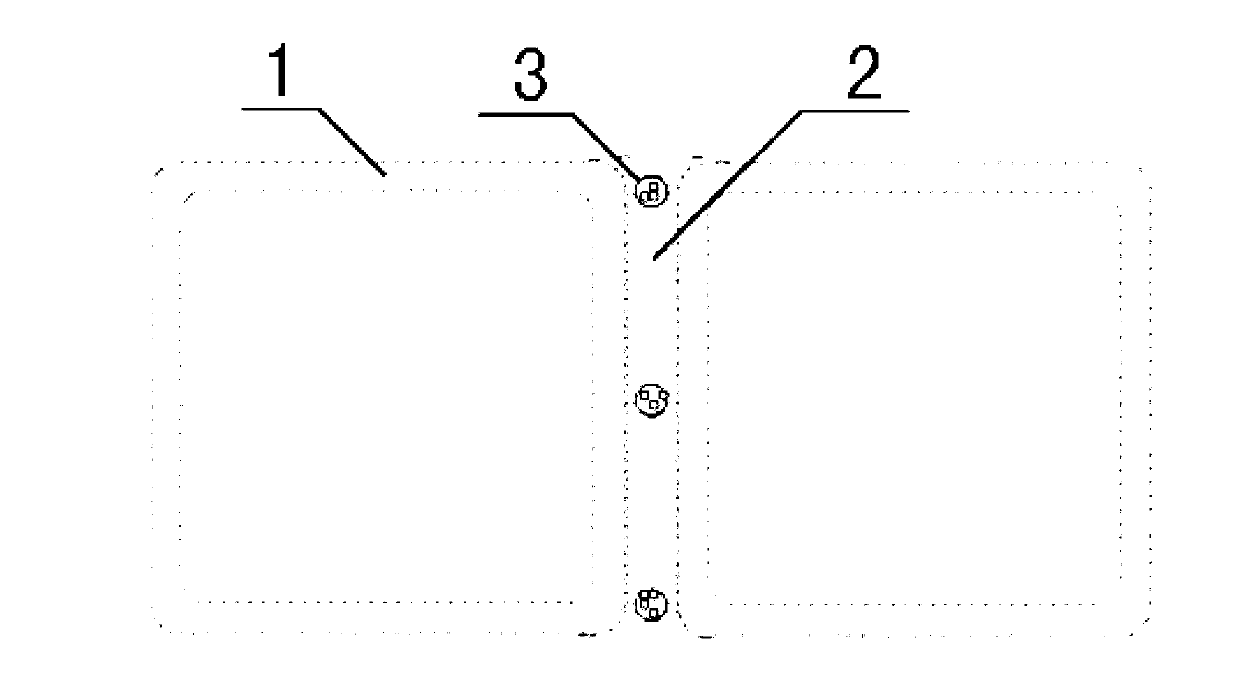

[0019] see figure 1 , with reference to figure 2 , image 3 , the glass fiber-reinforced hollow-walled polyethylene winding pipe of the present invention is formed by spirally winding a polyethylene hollow rectangular plastic pipe 1 and welding with hot melt adhesive 2, while spirally winding and welding with hot melt adhesive, synchronously winding with 1-100 A PP / PE compound-coated long glass fiber bundle 3 is bonded together with hot melt adhesive 2 between two adjacent polyethylene hollow rectangular plastic pipes. The diameter of the PP / PE composite coated long glass fiber bundle is 1-5mm.

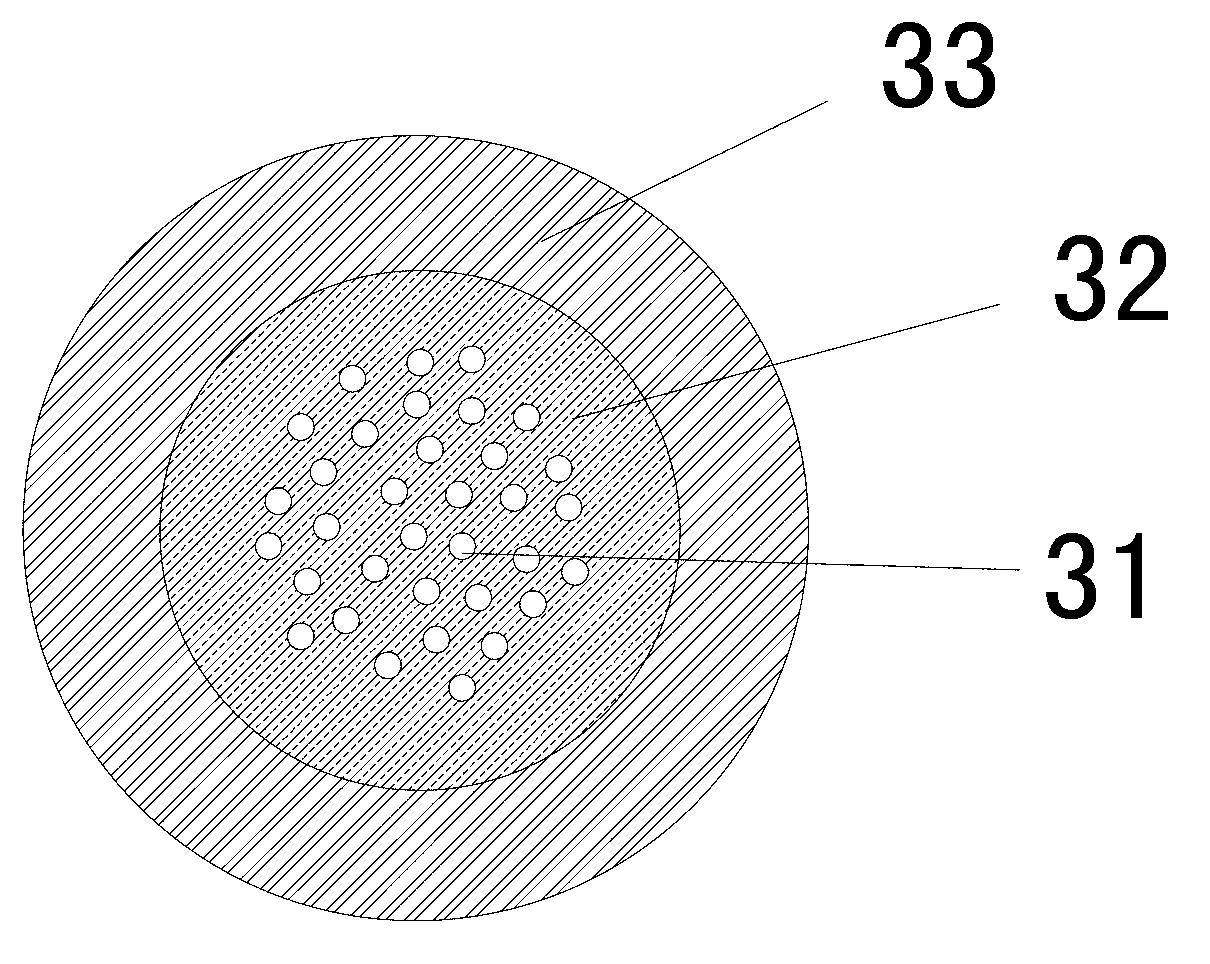

[0020] see image 3 , the PP / PE composite coated long glass fiber strands 3 in the present invention are compounded by continuous glass fiber strands 31, polypropylene resin 32 and polyethylene resin 33, wherein the continuous glass fiber strands 31 are uniformly dispersed in the poly The acrylic resin 32 is inside and wrapped by the polypropylene resin, and the polyethylene resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com