A kind of preparation method of resin substitute home improvement material

A technology for resin and home improvement, applied in the field of resin replacement for home improvement materials, can solve the problems of wood being easily corroded, frequent natural disasters, air pollution, etc., and achieve the effects of reducing wood loss, preventing natural disasters, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

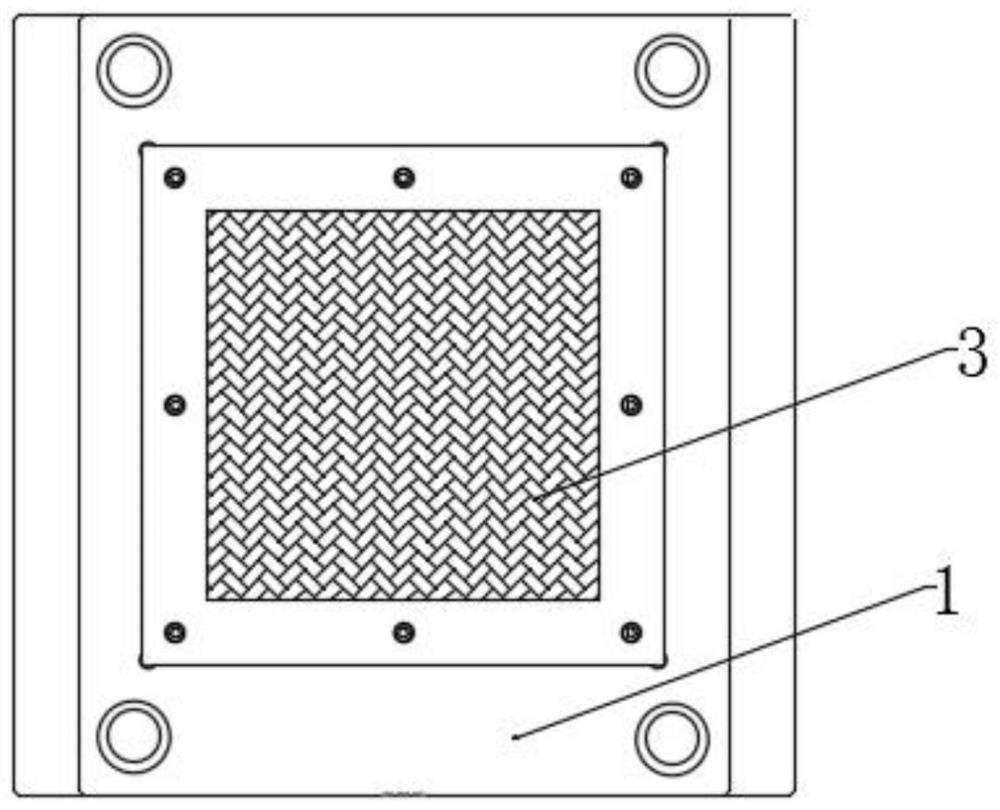

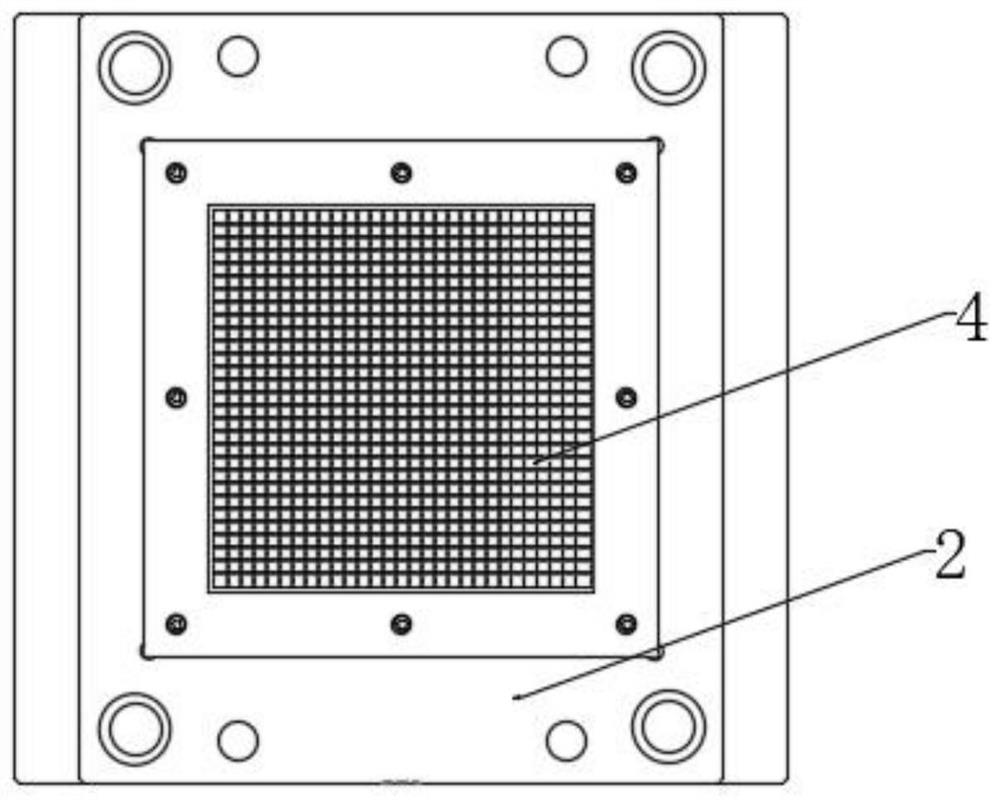

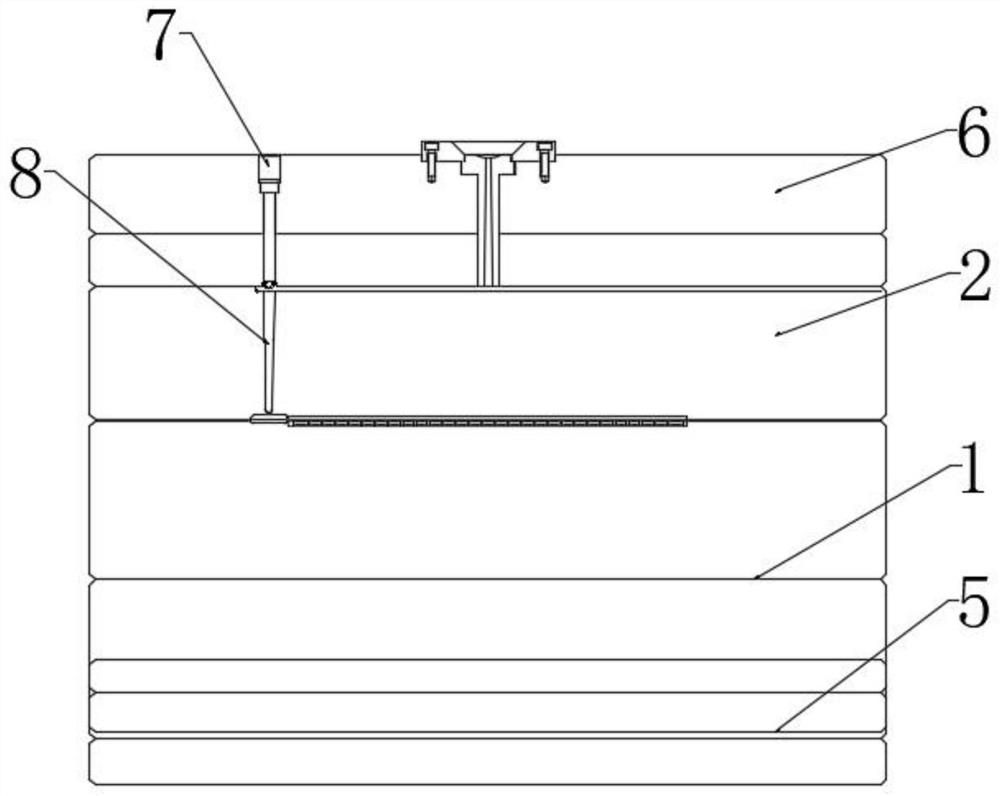

Image

Examples

Embodiment 1

[0038] A preparation method of resin substitute home decoration material, comprising the steps of:

[0039] Step 1: The first resin is ABS. First, dry the ABS. Dry the ABS at 80°C for 2 hours to reduce the moisture content to 0.13%, so as to prevent the moisture from being heated and evaporated during the molding process, which will cause the resin to crack. Bubbles, expansion, and problems such as silver threads, bubbles, poor transparency, and paste spots on the product, and then heat the dried ABS at 180°C, and then fill the heated ABS into the double-shot resin In the A barrel of the molding machine, the temperature of the A barrel of the two-shot resin molding machine is equal to the ABS heating temperature;

[0040] Step 2: Use PMMA as the second resin. First, dry the PMMA. Dry the PMMA at 80°C for more than 3 hours to reduce the moisture content to 0.13%. Then heat the dried PMMA. The PMMA heating temperature is 160°C. Then add luminous powder and pigments into the hea...

Embodiment 2

[0048] A preparation method of resin substitute home decoration material, comprising the steps of:

[0049] Step 1: The first resin is made of PP, which is very stable to water, and its water absorption rate in water is only 0.01%, so there is no need to dry it, and then heat the PP at 220°C, and then fill the heated PP Into the A barrel of the two-shot resin molding machine, the temperature of the A barrel of the two-shot resin molding machine is equal to the PP heating temperature;

[0050] Step 2: Use PC as the second resin. First, dry the PC at 120°C for more than 18 hours to reduce the water content to 0.03%. Then heat the dried PC at 330°C. Add luminous powder and pigment into the heated PC, stir evenly, then fill the stirred PC into the B barrel of the double-shot resin molding machine, the temperature of the B barrel of the double-shot resin molding machine is equal to the PC heating temperature ;

[0051] Step 3: Use three-dimensional numerical control technology to...

Embodiment 3

[0058] A preparation method of resin substitute home decoration material, comprising the steps of:

[0059] Step 1: The first resin is PC+ABS resin. PC+ABS resin is a copolymer blended with 30% ABS and 70% PC, and has the comprehensive characteristics of both PC and ABS. For example, the easy processing characteristics of ABS and the excellent mechanical properties and thermal stability of PC, the ratio of the two will affect the thermal stability of PC+ABS resin, and the mixed material of PC+ABS resin also shows excellent flow characteristics. First, PC +ABS resin for drying treatment, dry the PC+ABS resin at 100°C for 3 hours to reduce the moisture to 0.04%, then heat the PC+ABS resin, the heating temperature of the PC+ABS resin is 240°C, and then heat the The final PC+ABS resin is filled into the A barrel of the two-shot resin molding machine, and the temperature of the A barrel of the two-shot resin molding machine is equal to the heating temperature of the PC+ABS resin; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com