Reinforced electric hot melting belt and connecting structure and method thereof for connecting reinforced plastic electric hot melting belt with plastic pipeline

A technology of electric heating belt and plastic pipe, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

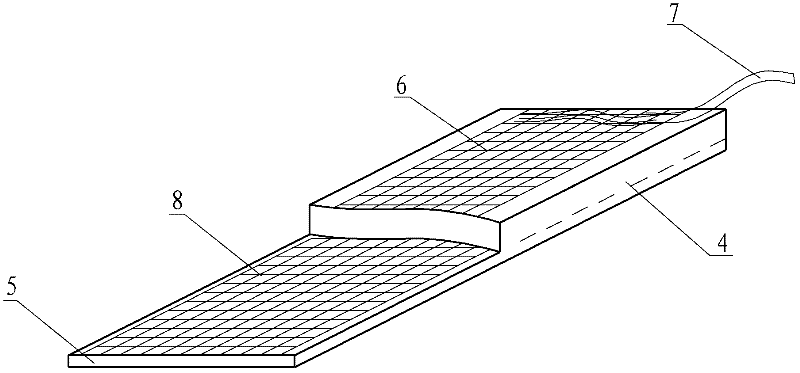

[0021] Such as figure 2 As shown, the plastic electric melting belt 4 reinforced by wire mesh or metal orifice plate of the present invention includes a thermoplastic strip 5, one side of the plastic strip 5 is press-fitted with a conductive metal mesh 6, and the conductive metal mesh 6 is on the The two ends in the length direction are connected with the conductive metal mesh 6 to connect the wire electrodes 7, and the plastic strip 5 is compounded with at least one layer of reinforced wire mesh or metal hole plate 8. The length of conductive metal net 6 is identical with the length of plastic strip 5, and the edge of longitudinal conductive metal net 6 is flush with the edge of plastic strip 5, and the width of conductive metal net 6 is slightly less than the width of plastic strip 5, and the width Each edge of the conductive metal mesh 6 is at an equal distance from the corresponding edge of the plastic strip 5 in the direction. Like this, can prevent the molten plastic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com