Fiber wrapped pipeline made from composite material

A technology for winding composite materials and composite materials, applied in the field of filament winding composite material pipes, can solve problems such as low axial tensile strength, and achieve the effects of light weight, low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

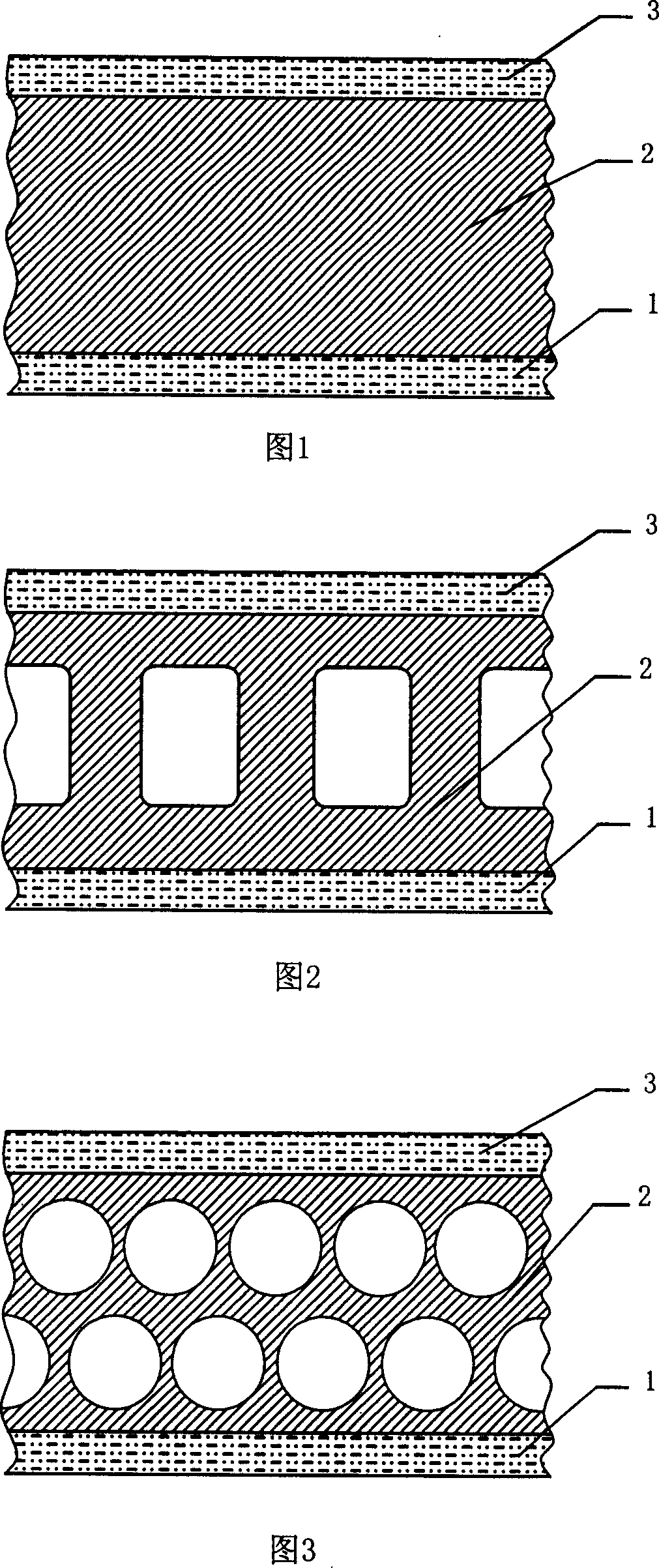

[0026] As shown in Figure 1, a fiber-wound composite material pipe has a pipe wall composed of an inner winding layer [1], a middle winding layer [2], and an outer winding layer [3].

[0027] The middle winding layer [2] is a dense structure, composed of thermoplastic composite materials, prepared using the following components (parts by weight):

[0028] Thermoplastic resin: 150 parts,

[0029] Filling: 350 parts.

[0030] Among them, the thermoplastic resin is modified coal tar pitch, and the filler is 200 parts of quartz sand, 100 parts of mineral crystal fiber and 50 parts of calcium carbonate.

[0031] The inner winding layer [1] is composed of a thermosetting composite material, prepared by the following components (components by weight):

[0032] Unsaturated polyester resin: 120 parts (containing 2% initiator),

[0033] Long staple and / continuous staple: 150 parts,

[0034] Filling: 2 servings.

[0035] Wherein, the long fiber is glass fiber, and its length is 250 ...

Embodiment 2

[0042] As shown in Figure 2, a fiber-wound composite material pipe, the pipe wall is composed of an inner winding layer [1], a middle winding layer [2], and an outer winding layer [3].

[0043] The middle winding layer [2] is a hollow structure, composed of thermoplastic composite materials, prepared using the following components (parts by weight):

[0044] Thermoplastic resin: 180 parts,

[0045] Short fiber: 100 parts,

[0046] Filling: 320 parts.

[0047] Among them, the thermoplastic resin is modified petroleum asphalt; the short fiber is glass fiber with a length of 5-15 mm; the filler is 50 parts of crystal fiber, 20 parts of heavy calcium carbonate, 50 parts of diatomite, and 20 parts of hollow glass microspheres .

[0048] The inner winding layer [1] and the outer winding layer [3] are composed of thermosetting composite materials, and are prepared with the following components (components by weight):

[0049] Unsaturated polyester resin: 120 parts (containing 1.5...

Embodiment 3

[0053] As shown in Figure 3, a fiber-wound composite material pipe, the pipe wall is composed of an inner winding layer [1], a middle winding layer [2], and an outer winding layer [3].

[0054] The middle winding layer [2] is a hollow structure, composed of thermoplastic composite materials, prepared using the following components (parts by weight):

[0055] Thermoplastic resin: 200 parts,

[0056] Short fiber: 120 parts,

[0057] Filling: 50 parts.

[0058] Wherein, the thermoplastic resin is unmodified petroleum asphalt, the short fiber is glass fiber with a length of 1-5 mm, and the filler is heavy calcium carbonate.

[0059] The inner winding layer [1] is composed of thermoplastic composite materials, and is prepared with the following components (parts by weight):

[0060]Thermoplastic resin: 200 parts,

[0061] Long staple and / continuous staple: 100 parts.

[0062] Among them, the thermoplastic resin is modified petroleum asphalt; the long fiber and / continuous fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com