Self-cleaning suiting containing nano-functional material and method for making garment products

A nano-functional, self-cleaning technology, applied in the field of clothing fabric processing, can solve the problems of detergent energy and resource waste, time-consuming and troublesome, etc., and achieve the effect of increasing service life and significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the padding treatment of pure wool fabric

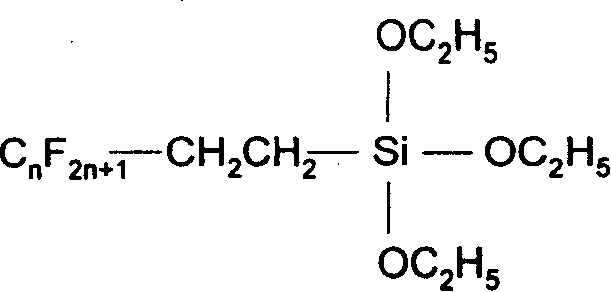

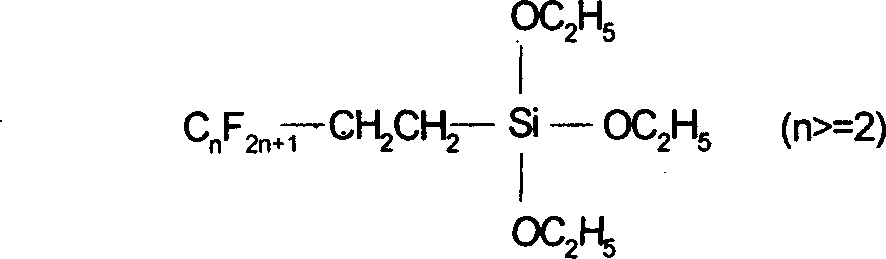

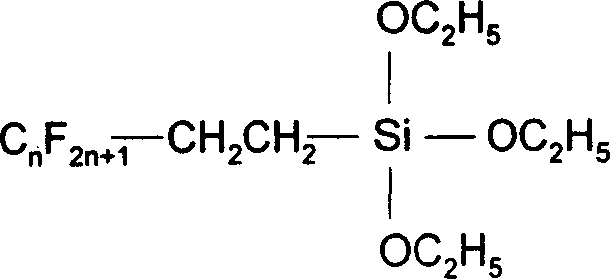

[0035] Put the pure wool fabric into the working fluid after the treatment current is 10A, the cloth speed is 15 m / min, and the surface treatment is carried out by low-temperature plasma. Triethoxysilane compound (wherein n=2) 1wt% ethanol solution, the bath ratio is 1:60, dipped at 20 ℃ for 1 minute, then squeezed out to make the liquid squeezed rate 80%, put it into the oven, and put it into the oven at 50 Pre-bake for 10 minutes at ℃, and continue to bake at 80℃ for 1.5 minutes to obtain nanometer self-cleaning pure wool fabric. The fabric (100% pure Australian wool) is used to make suits.

Embodiment 2

[0036] Embodiment 2: the padding treatment of wool polyester fabric

[0037] Put the wool polyester fabric (60% Australian wool, 40% polyester) into the working solution after the treatment current is 10A, the cloth speed is 15 m / min, and the surface is treated with low-temperature plasma. Silicon oxide 0.2wt%, fluorine-containing alkyl triethoxysilane compound (wherein n=6) 1.2%, bath ratio is 1:60, dipped at 20 ℃ for 1 minute, then squeezed out to make the squeezed out rate 80% , put it into an oven, pre-bake at 50°C for 10 minutes, and continue to bake at 70°C for 1.5 minutes to obtain a nanometer self-cleaning wool-polyester fabric.

Embodiment 3

[0038] Embodiment 3: the spray treatment of pure wool fabric

[0039] After the Australian wool fabric is subjected to low-temperature plasma surface treatment at room temperature, with a treatment current of 20A and a cloth speed of 10 m / min, a working fluid is used, which consists of 1.5 wt% zinc oxide with an average particle size of 50 nm, fluorine-containing alkyl Triethoxysilane compound (wherein n=8) 2wt% ethanol solution sprays the fabric after the above-mentioned air low-temperature plasma treatment, then puts into the oven, pre-baked at 40°C for 10 minutes, and continued to bake at 80°C for 1 minute , to get the nano wool self-cleaning fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com