Preparation method of self-cleaning leather or product containing nano functional material

A nano-functional, self-cleaning technology, applied in the field of self-cleaning leather or product preparation, can solve the problem of no leather self-cleaning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

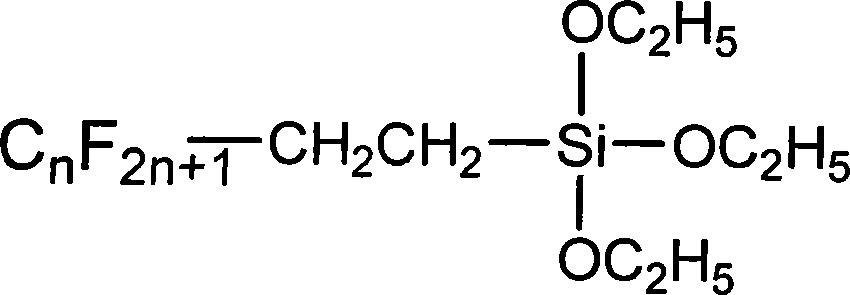

[0013] Example 1: 1) First, mix nanoscale solid particle silicon oxide with a particle size of 10 to 100 nm and an ethanol solution containing a fluorine-containing alkyl triethoxysilane compound to form a mixed solution, wherein the nanoscale solid particles account for 2% of the mass, the fluorine-containing alkyl triethoxysilane compound accounts for 0.2% of the mass of the mixed solution, and the balance is ethanol; then, the dyed, oiled, and dried The cowhide shoe upper leather after finishing is immersed in the mixture for 10-60 minutes at a dipping temperature of 15° C., hung to dry naturally, and then dried at 70° C.

Embodiment 2

[0014] Example 2: 1) First, mix nanoscale solid particle silicon nitride with a particle size of 10 to 100 nm and an ethanol solution containing a fluorine-containing alkyl triethoxysilane compound to form a mixed solution, wherein the nanoscale solid particle accounts for the mixed solution. 0.1% of the liquid mass, the fluorine-containing alkyl triethoxysilane compound accounts for 4% of the mixed liquid mass, and the balance is ethanol; then, the dyed, oiled, and After drying and finishing, the sheepskin clothing leather is immersed in the mixed solution for 10-60 minutes at a dipping temperature of 40°C, hung to air naturally, and then dried at 50°C.

Embodiment 3

[0015] Embodiment 3: 1) First, the nano-scale solid particle hydrotalcite with a particle size of 10 to 100 nm and the ethanol solution of a fluorine-containing alkyl triethoxysilane compound are mixed to form a mixed solution, wherein the nano-sized solid particle accounts for 0.8% of the mass, the fluorine-containing alkyl triethoxysilane compound accounts for 0.01% of the mass of the mixed solution, and the balance is ethanol; then, the cowhide shoe upper leather is immersed in the mixed solution under the condition that the bath ratio is 1:60 by dipping method 10-60 minutes, the impregnation temperature is 60 ℃, hang to dry naturally, and then dry at 40 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com