Preparation method of feather dress fabric or slopwork productions with nanometer self-cleaning function

A down jacket fabric, nanometer self-cleaning technology, applied in the field of garment fabric processing, can solve the problems of easy adsorption of dust and impurities, large water consumption, environmental pollution, etc., and achieve significant social and economic benefits and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: pure polyester fabric treatment

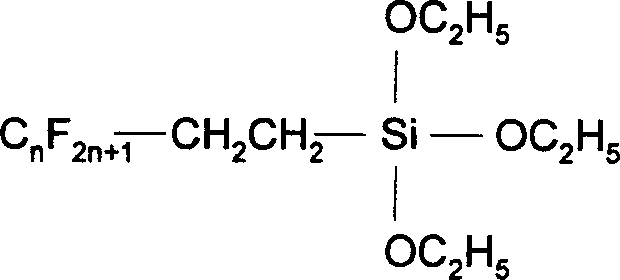

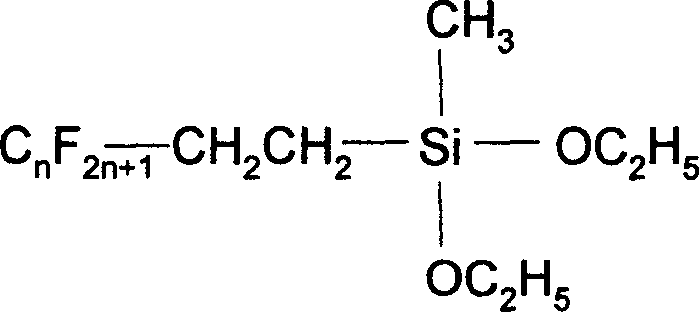

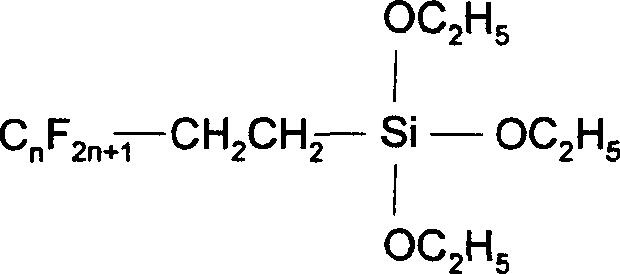

[0029] The pure polyester fabric is treated with a current of 20A and treated with a low-temperature plasma at a cloth speed of 5 minutes, and then sprayed with a working fluid. The working fluid consists of 0.3wt% titanium oxide with an average particle size of 20nm, Diethoxysilane compound (wherein n=16) 1wt% ethanol solution, the bath ratio is 1:60, spray at room temperature to make the liquid-carrying rate 80%, put it into an oven, and pre-bake it at 40°C for 15 minutes , to obtain a polyester fabric with self-cleaning function.

Embodiment 2

[0030] Embodiment 2: the processing of nylon fabric

[0031] The pure nylon fabric is treated with a current of 30A and treated with a low-temperature plasma at a cloth speed of 3 minutes, and then it is sprayed with a working fluid. Diethoxysilane compound (wherein n = 16) 2wt% ethanol solution, the bath ratio is 1:60, spray at room temperature to make the liquid-carrying rate 80%, put it into an oven, and dry it at 30°C for 30 minutes , to obtain nylon fabric with self-cleaning function.

Embodiment 3

[0032] Embodiment 3: the processing of polyester / cotton blended fabric

[0033] The polyester / cotton blended fabric (polyester / cotton, 60 / 40) is treated with a current of 5A at room temperature and treated with a low-temperature plasma at a cloth speed of 30 minutes, and then sprayed with a working fluid. The composition of the working fluid is 2.5wt% of zinc oxide with an average particle diameter of 50nm, 2.5wt% ethanol solution of fluorine-containing alkyl diethoxysilane compound (n=18) sprays the fabric after the above-mentioned low-temperature plasma treatment, and then dries naturally at room temperature , to obtain polyester / cotton blended fabric with self-cleaning function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com