Device and method for automatically cleaning extractor hood

A technology for automatic cleaning and range hood, which is used in the removal of oil fume, heating methods, and household heating, etc., can solve the problems of increased cost and inability to completely remove oil stains from leaves, and achieves low processing cost, convenient operation and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

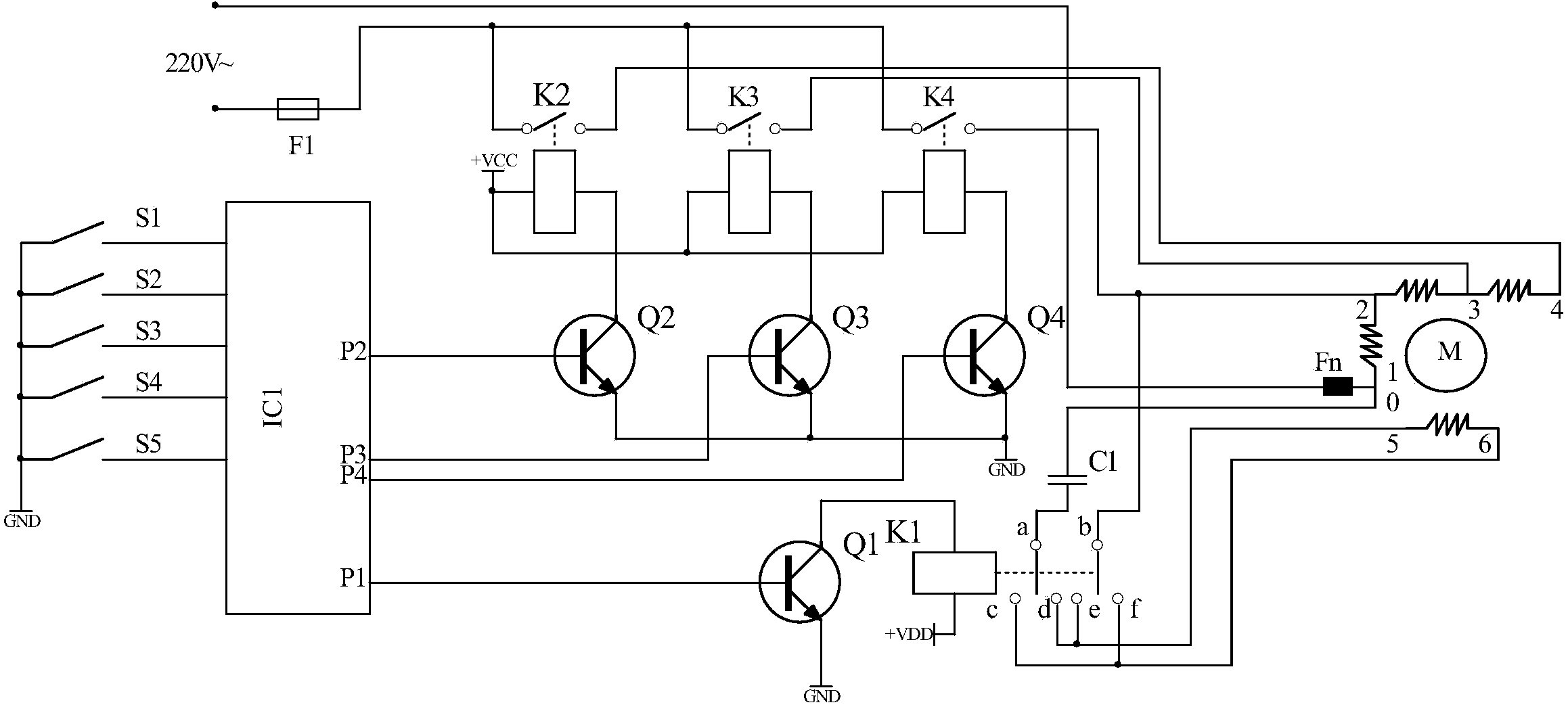

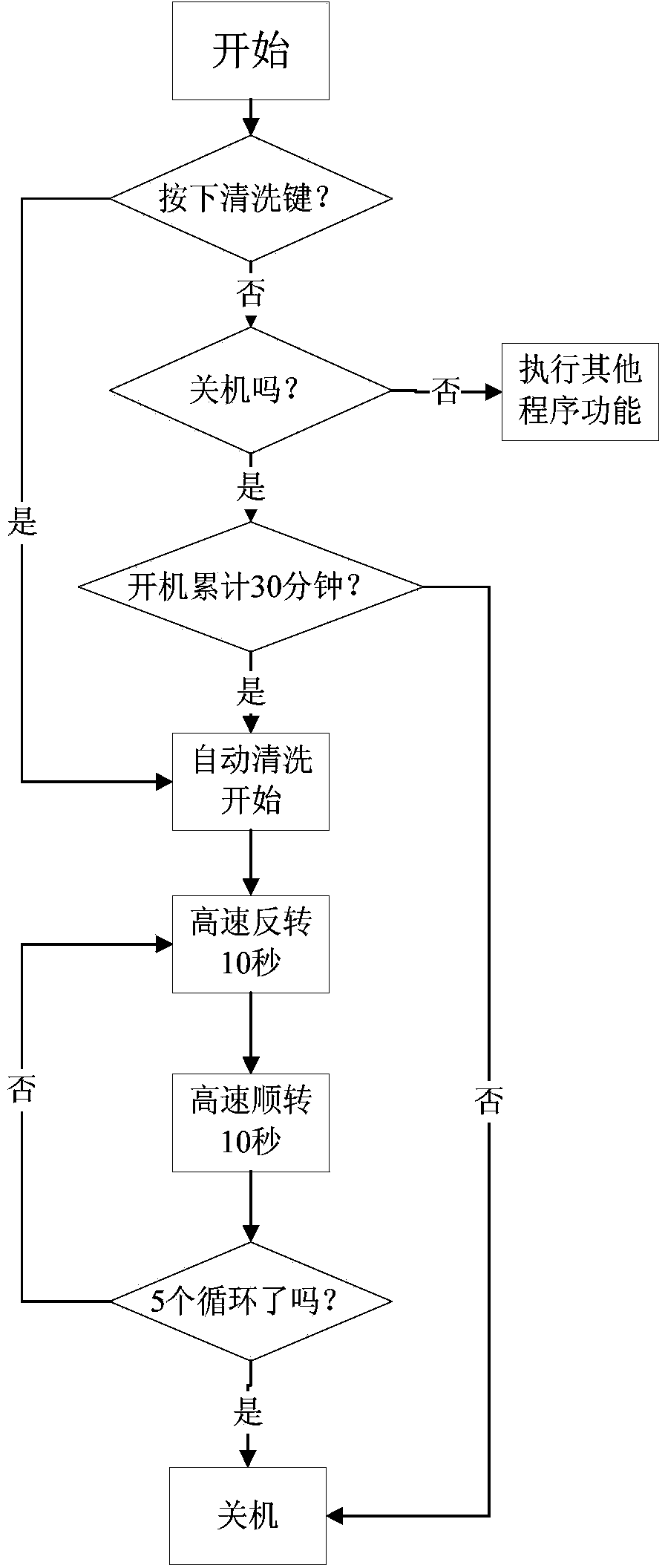

[0022] The following is attached figure 1 , 2 The present invention is described in further detail with regard to using single-phase AC motor:

[0023] refer to figure 1 , an automatic cleaning device for range hoods, including a motor M for driving the impeller, a forward and reverse control circuit for the motor, and a forward and reverse control circuit for driving the motor to perform several preset cycles of alternating forward and reverse rotations after the motor works for a set time. The cycle further drives the controller IC1 for automatic centrifugal cleaning of the impeller.

[0024] In order to facilitate the user to start the automatic cleaning program at any time, it also includes an automatic cleaning operation switch S4 that manually sends instructions to the controller to drive the motor through the forward and reverse control circuit to perform several preset cycles of forward and reverse alternate cycles. In addition, there are start switch S1, wind speed...

Embodiment 2

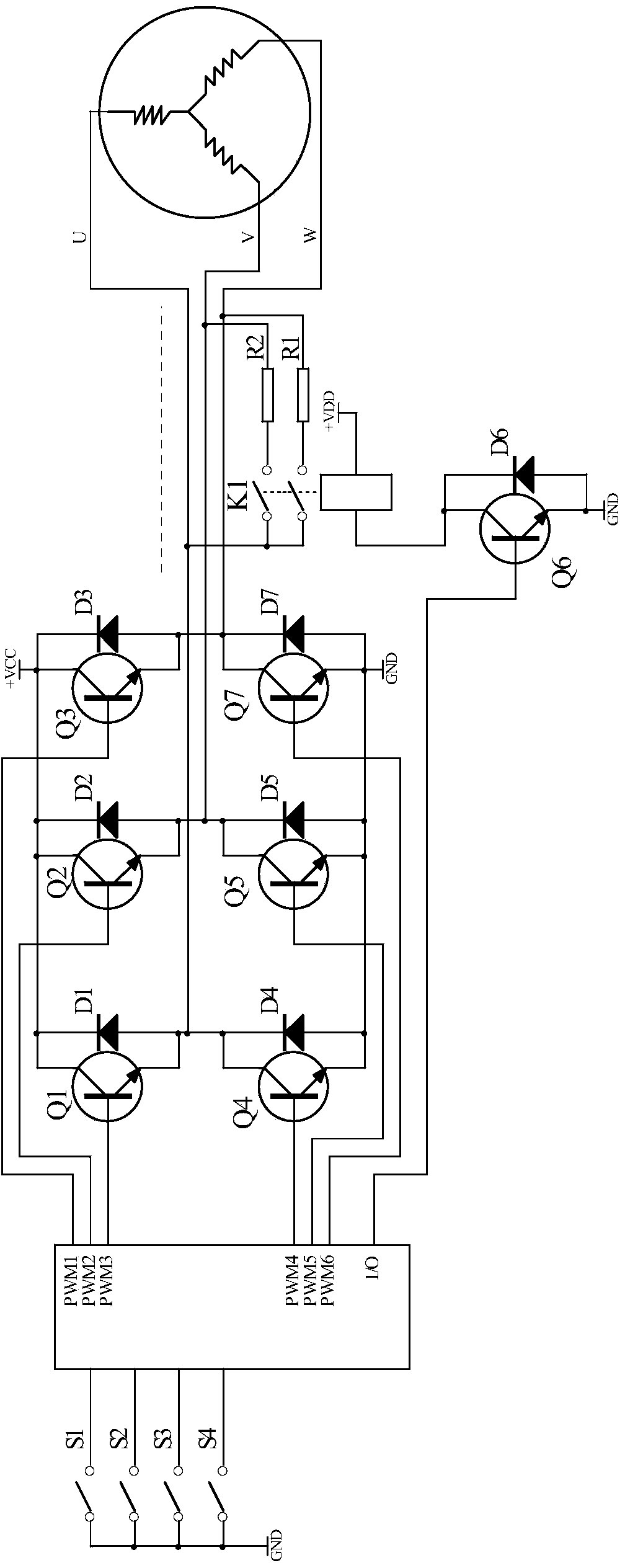

[0038] In this embodiment, the motor adopts a DC brushless motor, combined with the attached image 3 , 4 The present invention is described in further detail:

[0039] refer to image 3 , the range hood self-cleaning device, also includes the motor for driving the impeller, the forward and reverse control circuit of the motor, and the forward and reverse control circuit for driving the motor to perform several preset cycles of alternating forward and reverse after the motor works for a set time The controller that circulates and then drives the automatic centrifugal cleaning of the impeller. The difference is that its motor is a DC brushless motor, and its three-phase running winding is connected to the output end of the controller through a PWM drive circuit. The U-phase and V-phase in the running winding And a braking resistor is connected between the U phase and the W phase through the same internal braking relay with a double-pole single-throw switch, and the control te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com