Preparation method of transparent super-hydrophobic coating

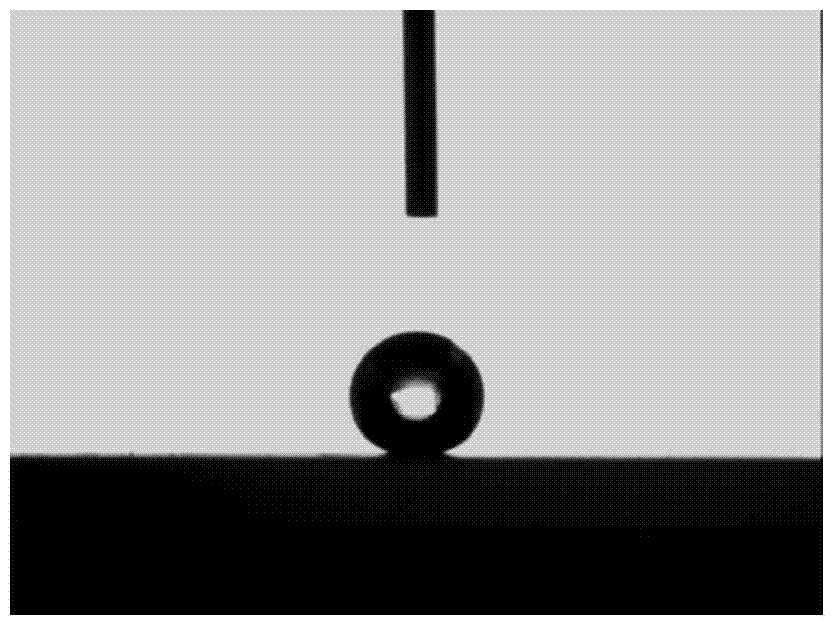

A super-hydrophobic coating and transparent technology, applied in the field of preparation of hydrophobic materials, can solve the problems of expensive raw materials, complex production process of transparent super-hydrophobic surface, special equipment used, etc. Optical, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of boehmite sol

[0045] The boehmite colloid was prepared by metal alkoxide hydrolysis, aluminum isopropoxide and nitric acid were added to water, and the molar ratio was controlled to be [H 2 O]:[AIP]:[HNO 3 ]=100:1:0.1, stirred vigorously at 90°C, accompanied by condensation and reflux, reacted for 24 hours, the solution was slightly cyan, and boehmite sol was obtained, which was cooled and sealed.

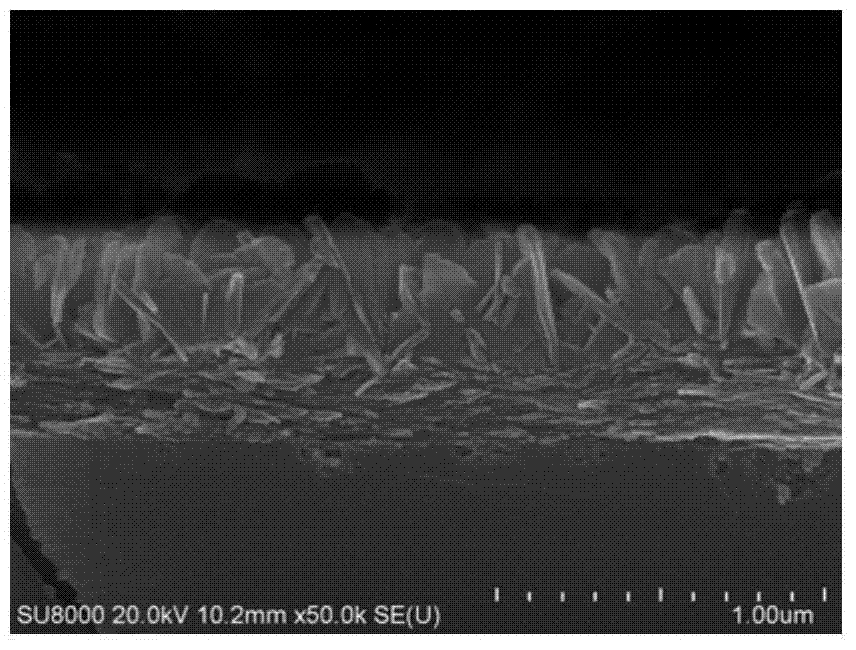

[0046] (2) Formation of seed film on the surface of substrate material

[0047] The boehmite seed film is formed on the surface of the base material by means of sol-gel and pull coating method. With the help of a puller, in the boehmite sol solution, the clean glass sheet is pulled and coated, and the thickness of the film can be controlled by adjusting the concentration of the boehmite sol or the number of pulls, and the thickness is controlled at 30nm to 200nm between.

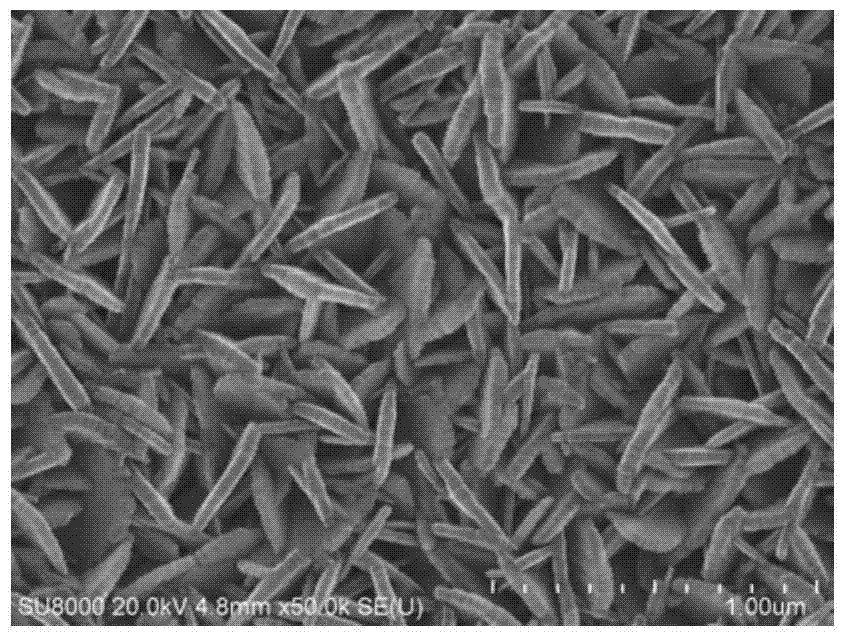

[0048] (3) Formation of rough surface with nanosheet structure

[0049] 0.12mo...

Embodiment 2

[0053] (1) Preparation of boehmite sol

[0054] The boehmite colloid was prepared by metal alkoxide hydrolysis, aluminum isopropoxide and nitric acid were added to water, and the molar ratio was controlled to be [H 2 O]:[AIP]:[HNO 3 ]=100:1:0.1, stirred vigorously at 90°C, accompanied by condensation and reflux, reacted for 24 hours, the solution was slightly cyan, and boehmite sol was obtained, which was cooled and sealed.

[0055] (2) Formation of seed film on the surface of substrate material

[0056] The boehmite seed film is formed on the surface of the base material by means of sol-gel and pull coating method. With the help of a puller, in the boehmite sol solution, the clean glass sheet is pulled and coated, and the thickness of the film can be controlled by adjusting the concentration of the boehmite sol or the number of pulls, and the thickness is controlled at 30nm to 200nm between.

[0057] (3) Formation of rough surface with nanosheet structure

[0058] 0.12mo...

Embodiment 3

[0062] (1) Preparation of boehmite sol

[0063] The boehmite colloid was prepared by metal alkoxide hydrolysis, aluminum isopropoxide and nitric acid were added to water, and the molar ratio was controlled to be [H 2 O]:[AIP]:[HNO 3 ]=100:1:0.1, stirred vigorously at 90°C, accompanied by condensation and reflux, reacted for 24 hours, the solution was slightly cyan, and boehmite sol was obtained, which was cooled and sealed.

[0064] (2) Formation of seed film on the surface of substrate material

[0065] The boehmite seed film is formed on the surface of the base material by means of sol-gel and pull coating method. With the help of a puller, in the boehmite sol solution, the clean glass sheet is pulled and coated, and the thickness of the film can be controlled by adjusting the concentration of the boehmite sol or the number of pulls, and the thickness is controlled at 30nm to 200nm between.

[0066] (3) Formation of rough surface with nanosheet structure

[0067] 0.12mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com