Nanometer composite ocean anticorrosion coating and preparation method thereof

A nano-composite material and marine anti-corrosion technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve problems such as poor compatibility, high economic cost, and easy phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

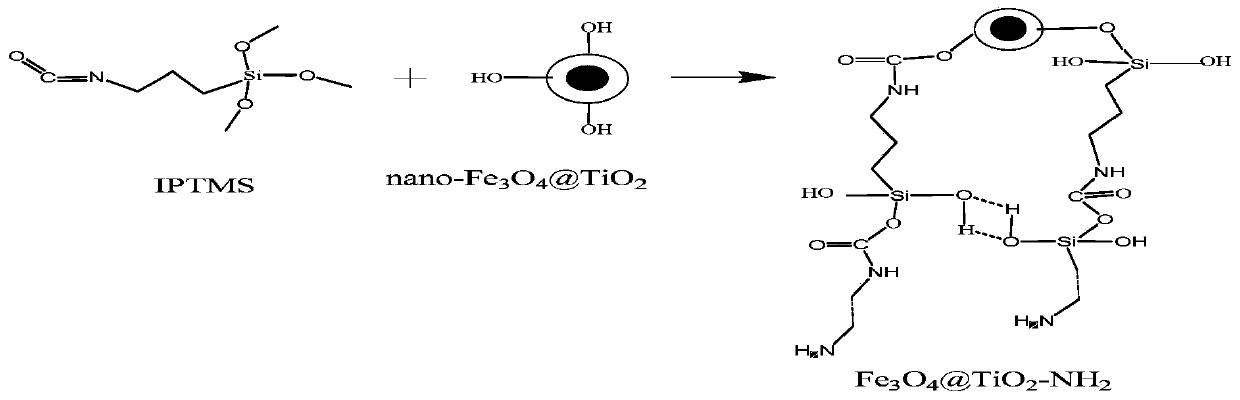

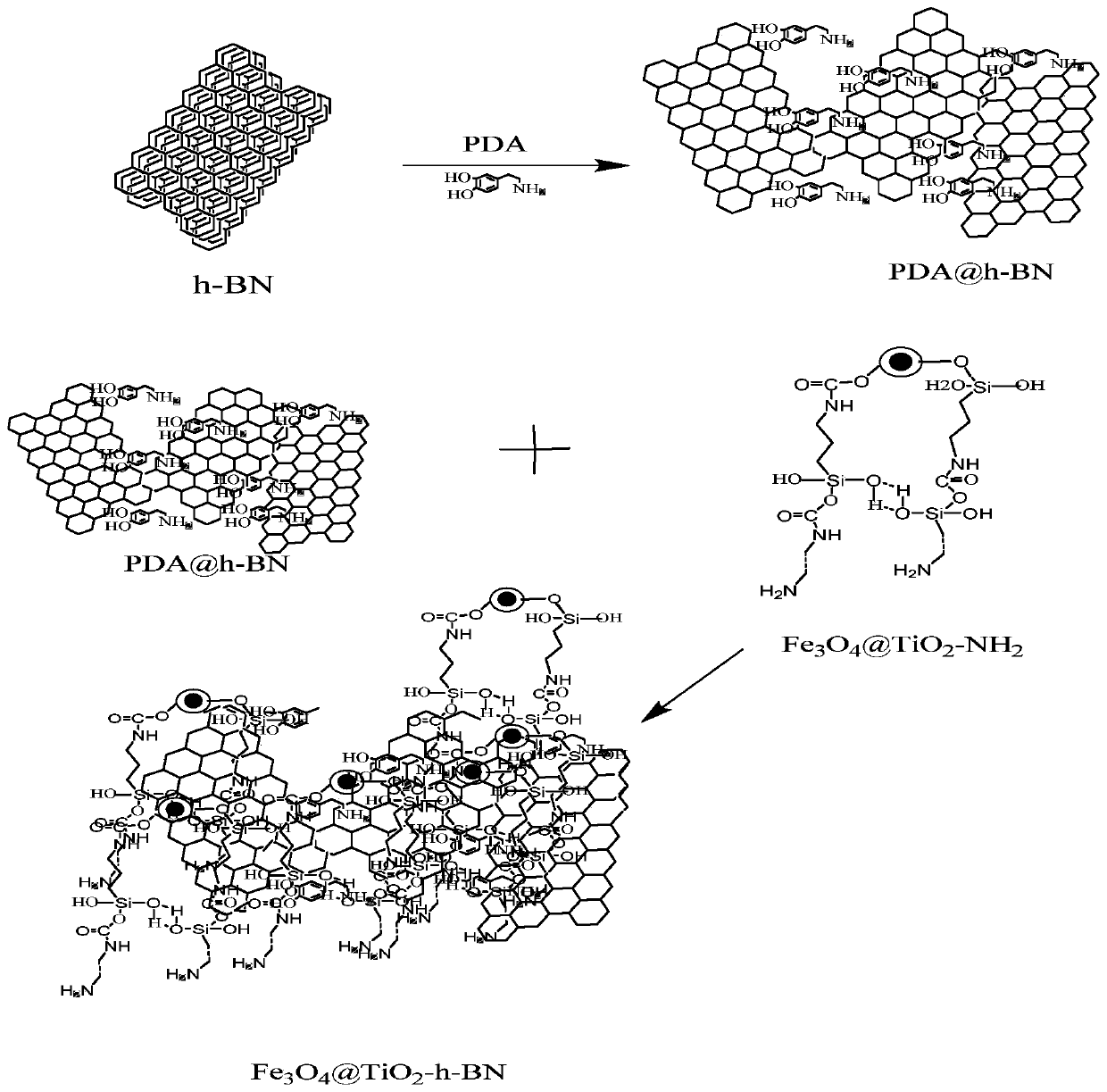

Method used

Image

Examples

preparation example Construction

[0060] Preparation of Hydroxy Epoxy Phosphate Dispersant (HEP):

[0061] A solution of bisphenol A epoxy resin E44 (20 g in 40 mL of acetone) was added dropwise to a solution of phosphoric acid (9.22 g of phosphoric acid in 20 mL of acetone, the molar ratio of phosphoric acid to epoxy group was 1:1) in 30 minutes vigorously After stirring for 30 minutes, the mixture was vigorously stirred until the acid value remained constant (97.23 mg KOH / g), after which N,N-dimethylethanolamine (11.27 g) and water were added dropwise to the mixture. After the reaction was completed, the solvent acetone was removed using a rotary vacuum evaporator to obtain a hydroxy epoxy phosphate dispersant.

Embodiment example 1

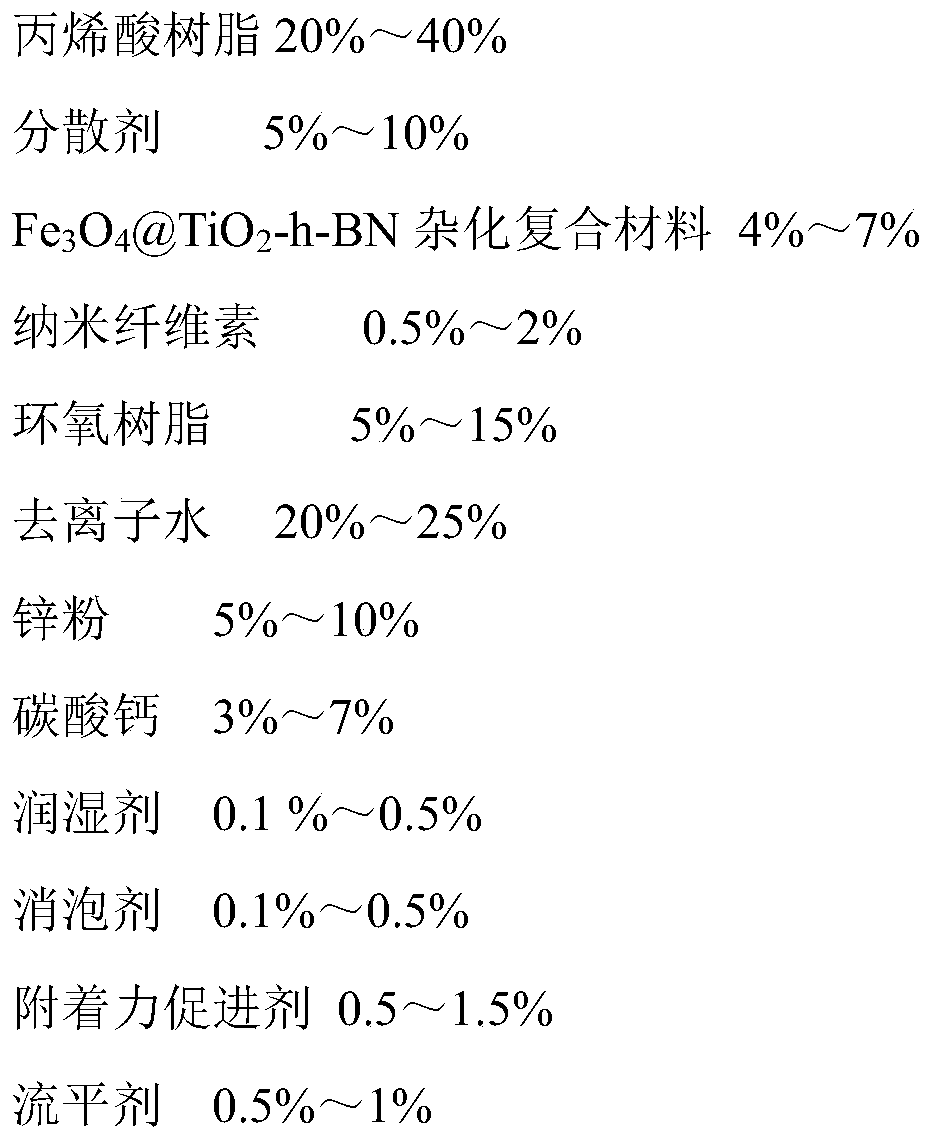

[0063] Add 32% water-based hydroxyl acrylic resin, 10% deionized water, pigments and fillers (calcium carbonate 4%, zinc powder 10%), other additives (defoamer 0.1%, adhesion promoter 0.2%, leveling 0.7% wetting and dispersing agent, 0.2% wetting and dispersing agent) high-speed stirring and mixing evenly, then add 7% water-based epoxy resin, and continue to stir for 30 minutes;

[0064] Step 2: Take 5% to implement case 1 to prepare Fe 3 o 4 @TiO 2 -h-BN hybrid composite material, 0.8% nano cellulose (NCC), 6% hydroxyl epoxy phosphate dispersant are mixed evenly, 10% deionized water is added to the mixed solution and ultrasonic dispersion is equipped with a cooling device at 500W Ultrasound in the instrument for 1h, get Fe 3 o 4 @TiO 2 -h-BN hybrid composite material mixed dispersion;

[0065] Step 3: Add the mixed dispersion obtained in Step 2 into the mixed solution obtained in Step 1 and continue ultrasonically dispersing evenly to obtain the A component of the nanoc...

Embodiment example 2

[0067] Add 25% water-based hydroxyl acrylic resin, 10% deionized water, pigments and fillers (calcium carbonate 3%, zinc powder 7%), other additives (defoamer 0.2%, adhesion promoter 0.2%, leveling 1%, wetting and dispersing agent 0.3%) high-speed stirring and mixing, then add 13% water-based epoxy resin, continue to stir for 30min;

[0068] Step 2: Take 4% Fe 3 o 4 @TiO 2 -h-BN hybrid composite material, 1.3% nano cellulose (NCC), 5% hydroxyl epoxy phosphate dispersant are mixed evenly, add 12% deionized water to the mixed solution and use a 500W ultrasonic disperser equipped with a cooling device Ultrasound for 1h, get Fe 3 o 4 @TiO 2 -h-BN hybrid composite material mixed dispersion;

[0069] Step 3: Add the mixed dispersion obtained in Step 2 into the mixed solution obtained in Step 1 and continue ultrasonically dispersing evenly to obtain Component A of the nanocomposite marine anti-corrosion coating, and finally add Component B, which is 18% water-based isocyanate c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com