Method for preparing self-cleaning anti-icing rubber surface by use of waste silicone rubber product

A technology of rubber surface and silicone rubber, which is applied in the field of surface chemistry, can solve the problem of difficult removal of ice, and achieve the effect of low cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

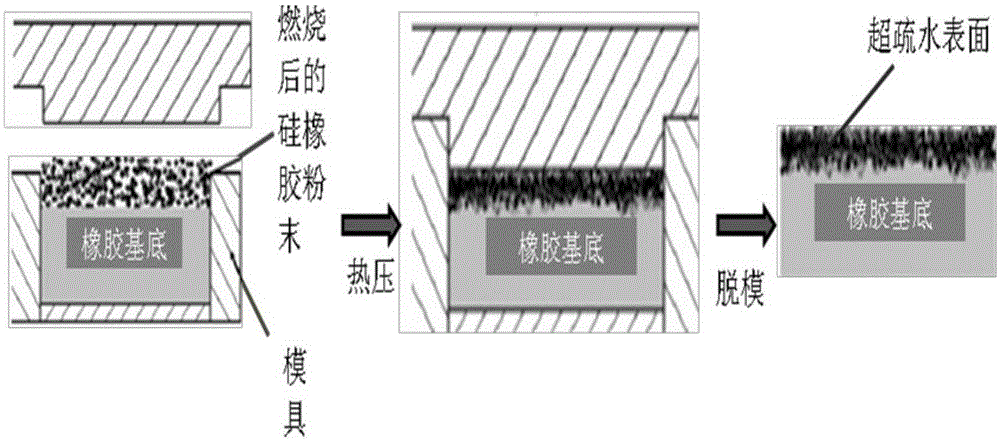

[0025] (1) Combustion of waste silicone rubber: Fully burn waste silicone rubber products in a muffle furnace at 300°C for 15 minutes, with a heating rate of 1-3°C / min. The obtained combustion product is ground into powder, and the particle size of the formed powder is about 800-1000nm.

[0026] (2) Forming the powder and rubber together: spread the powder obtained in the previous step evenly with a sieve to a thickness of 1mm on the surface of the formed mixed rubber, and put the powdered rubber into the mold.

[0027] (3) Hot press vulcanization: in a flat vulcanizer, adopt the vulcanization conditions of 145° C. and 12 MPa, and hot press vulcanize for 60 minutes.

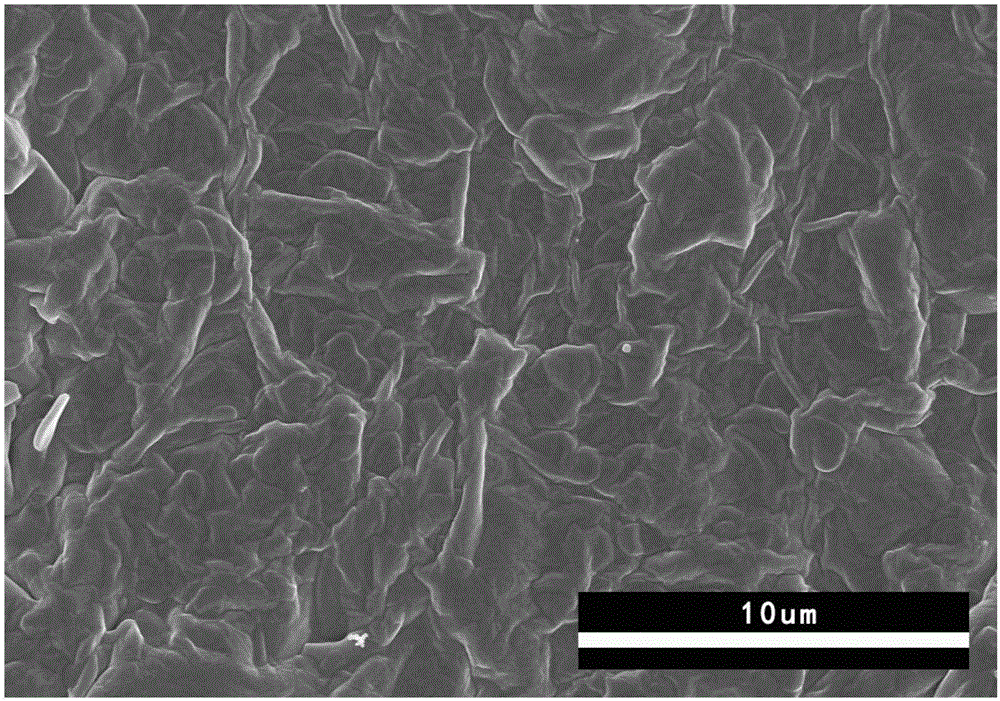

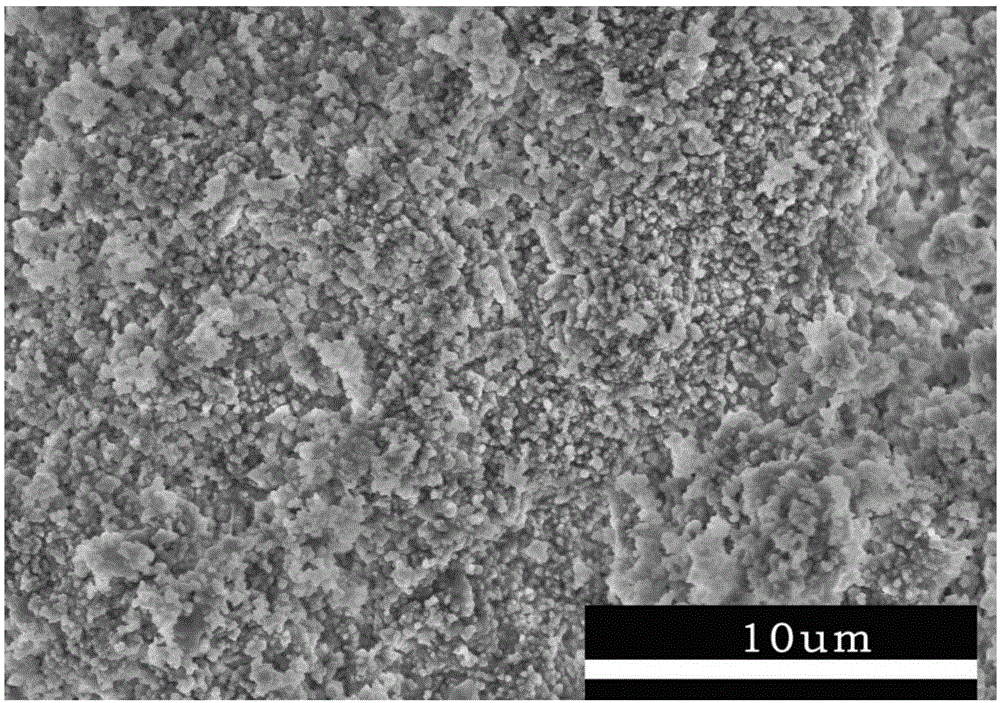

[0028] (4) Post-demolding treatment: open the mold and take out the hot-pressed vulcanized rubber, soak it in ethanol and ultrasonically clean it at a frequency of 30 Hz for 5 minutes, and clean the surface with deionized water. Wash off the powder that is not pressed into the surface, and dry at 30°C. A layer ...

Embodiment 2

[0032] (1) Combustion of waste silicon rubber: In the present invention, waste silicon rubber products are fully burned in a muffle furnace at 450° C. for 10 minutes, and the heating rate is 1-3° C. / min. The obtained combustion product is ground into powder, and the particle size of the formed powder is about 500-1000nm.

[0033] (2) Molding the powder and rubber together: spread the powder obtained in the previous step evenly with a sieve to a thickness of 0.5 mm on the surface of the formed mixed rubber, and put the powdered rubber into the mold.

[0034] (3) Hot press vulcanization: in a flat vulcanizer, adopt the vulcanization conditions of 150°C and 14MPa, and hot press vulcanize for 40 minutes.

[0035] (4) Post-demolding treatment: open the mold and take out the hot-pressed vulcanized rubber, soak it in ethanol and ultrasonically clean it at a frequency of 40 Hz for 10 minutes, and clean the surface with deionized water. Wash away the powder that is not pressed into th...

Embodiment 3

[0039] (1) Combustion of waste silicon rubber: In the present invention, waste silicon rubber products are fully burned in a muffle furnace at 600° C. for 5 minutes, and the heating rate is 1-3° C. / min. The obtained combustion product is ground into powder, and the particle size of the formed powder is about 200-500nm.

[0040] (2) Forming the powder and rubber together: spread the powder obtained in the previous step evenly with a sieve to a thickness of 0.2mm on the surface of the formed mixed rubber, and put the powdered rubber into the mold.

[0041] (3) Hot press vulcanization: in a flat vulcanizer, adopt the vulcanization conditions of 180°C and 16MPa, and hot press vulcanize for 30 minutes.

[0042] (4) Post-demolding treatment: open the mold and take out the hot-pressed vulcanized rubber, soak it in ethanol and ultrasonically clean it at a frequency of 50 Hz for 10 minutes, and clean the surface with deionized water. Wash away the powder that is not pressed into the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com