Preparation process for superaqueous surrounding-separating coating material of PVC

A preparation process and coating material technology, which is applied in the field of chemical industry, can solve the problems of easy dust sticking, cracking, product failure and other problems, and achieve the effects of good air tightness, long service life and superior wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

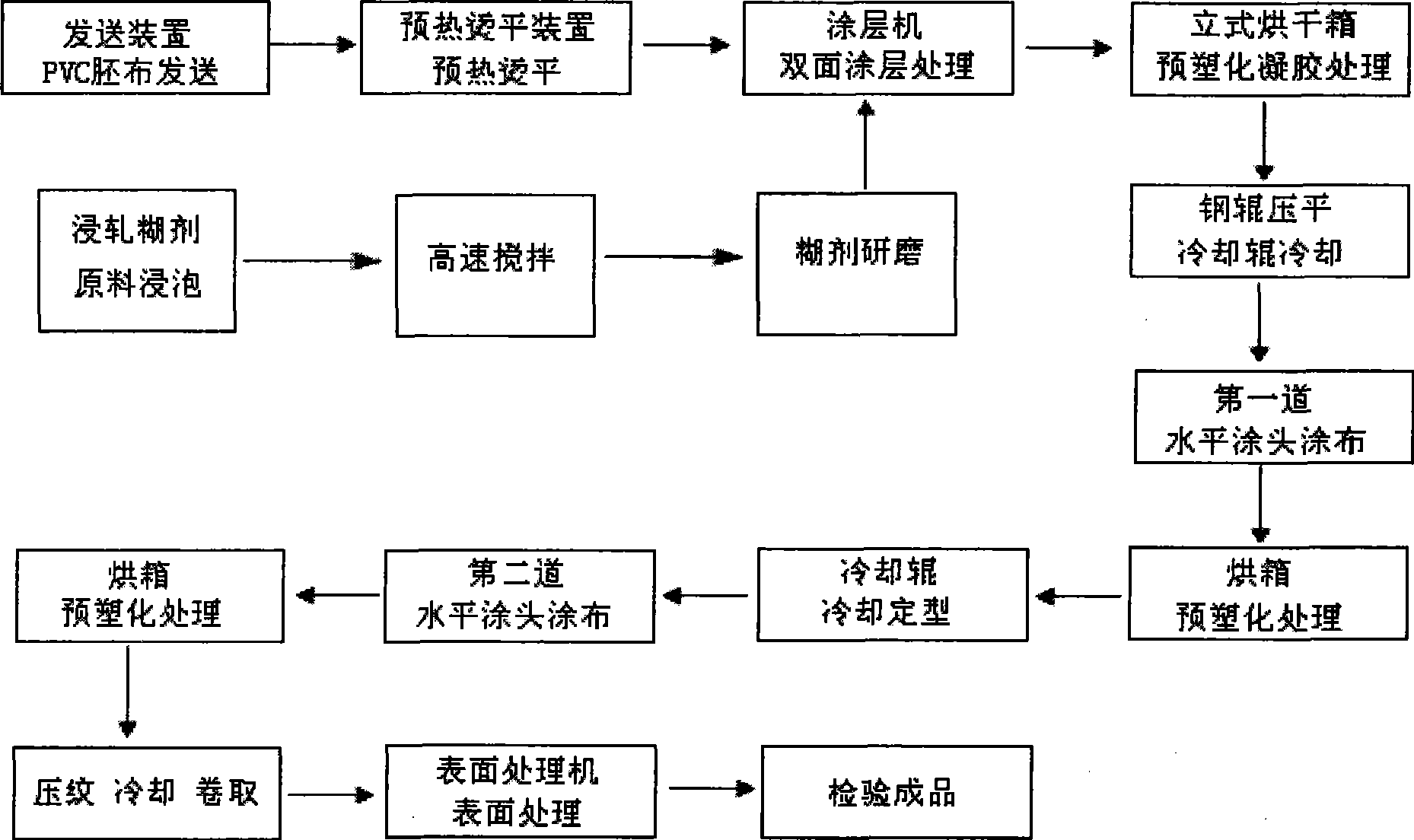

Image

Examples

Embodiment 1

[0031] The polyester gray cloth used can be high-strength polyester gray cloth.

[0032] The specific steps of the preparation process are:

[0033] 1) Sending: the high-strength polyester gray cloth is placed on the sending device for sending, and one end of the core tube on the sending device is equipped with a magnetic brake device to adjust the tension;

[0034] 2) Preheating and ironing: the gray cloth is preheated and ironed through the preheating and ironing device on the sending device; this step is a set of heating steel rollers, and the temperature is controlled at 80 degrees to ensure that the moisture in the fabric and the low molecular weight Volatile matter is excluded here to prevent pinholes from escaping in subsequent coatings from affecting airtightness;

[0035] 3) Double-sided coating treatment: use a coating machine to paste the paste with a padding vertical scraper, dip the preheated and flattened gray cloth into the paste so that the warp and weft yarns...

Embodiment 2

[0052] The polyester gray cloth used can be high-strength polyester gray cloth.

[0053] The specific steps of the preparation process are:

[0054] 1) Sending: the high-strength polyester gray cloth is placed on the sending device for sending, and one end of the core tube on the sending device is equipped with a magnetic brake device to adjust the tension;

[0055] 2) Preheating and ironing: the gray cloth is preheated and ironed through the preheating and ironing device on the sending device; this step is a set of heating steel rollers, and the temperature is controlled at 120 degrees to ensure that the moisture in the fabric and the low molecular weight Volatile matter is excluded here to prevent pinholes from escaping in subsequent coatings from affecting airtightness;

[0056] 3) Double-sided coating treatment: use a coating machine to paste the paste with a padding vertical scraper, dip the preheated and flattened gray cloth into the paste so that the warp and weft yarn...

Embodiment 3

[0073] The specific steps of the preparation process are:

[0074] 1) Sending: the high-strength polyester gray cloth is placed on the sending device for sending, and one end of the core tube on the sending device is equipped with a magnetic brake device to adjust the tension;

[0075] 2) Preheating and ironing: the gray cloth is preheated and ironed through the preheating and ironing device on the sending device; this step is a set of heating steel rollers, and the temperature is controlled at 100 degrees to ensure that the moisture in the fabric and the low molecular weight Volatile matter is excluded here to prevent pinholes from escaping in subsequent coatings from affecting airtightness;

[0076] 3) Double-sided coating treatment: use a coating machine to paste the paste with a padding vertical scraper, dip the preheated and flattened gray cloth into the paste so that the warp and weft yarns of the cloth are filled with paste, and then pass through a pair of rolls Roll o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com