Method for enhancing surface wettability of hexagonal-prism-structure nano zinc oxide material

A nano-zinc oxide and hexagonal technology, applied in electrolytic inorganic material coating and other directions, can solve the problems of ZnO surface wettability without relevant research, and achieve the effect of low reaction equipment requirements, no environmental pollution, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are given and the present invention is described in conjunction with the given embodiments, but the given embodiments do not constitute any limitation to the present invention:

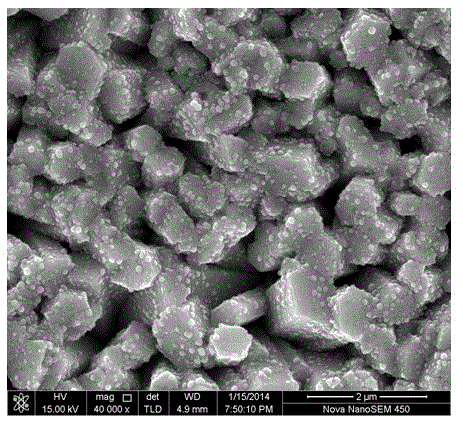

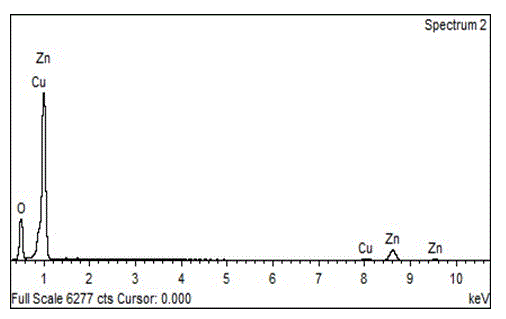

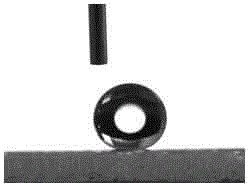

[0021] Specific embodiment one: preparation concentration is the copper sulfate solution of 0.005 mol / L, adjusts the pH value of solution with 1.5 mL lactic acid, sodium hydroxide to be 11; In two-electrode system, wherein graphite electrode is anode, 1.5 cm*5 cm The ITO glass sheet is used as the cathode, and the electrochemical deposition is carried out under the conditions of constant voltage 2.5 V and constant temperature 50 ℃, and the deposition time is 10 s; After annealing for 4 hours, the cuprous oxide with a specific structure on the hexagonal prism zinc oxide is obtained, and the electrodeposited ITO electrode is placed in a perfluorooctyltriethoxysilane with a volume ratio of 1:1000. Soak in ethanol solution for 24 h; take out the soaked ITO e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com