Nano super-hydrophobic coating and production technology thereof

A super-hydrophobic coating, nano-technology, applied in coatings, anti-fouling/underwater coatings, biocide-containing paints, etc., can solve the problems of limiting the research and preparation of super-hydrophobic materials, and the difficulty of wide-scale application of super-hydrophobic materials. , to achieve the effect of small rolling angle, low production cost and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

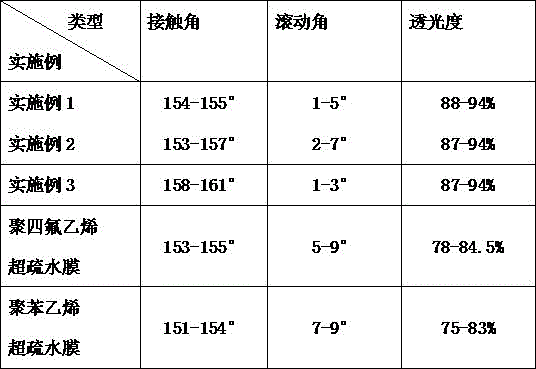

Examples

Embodiment 1

[0018] A nano-superhydrophobic coating, the coating is composed of the following materials according to mass percentage: 180 parts of nano-silica, 120 parts of hexamethyldisilazane, 450 parts of solvent, 420 parts of silicone resin and 8 parts of curing agent , wherein the particle size of nano-silica is 10-30 nanometers, the curing agent is aliphatic polyamine, and the solvent is absolute ethanol, n-propanol, isopropanol, acetone, tetrahydrofuran, N, N-two A combination of one or more of methylacetamide or N,N-dimethylformamide, toluene and xylene.

[0019] A kind of production technique of nano superhydrophobic coating and, comprises the following steps:

[0020] S1: Preparation of filler solution: adding nano-silica and hexamethyldisilazane to the solvent to dilute, stirring ultrasonically for 15 minutes or high-speed ball milling for 60 minutes, and standing for 24 hours to obtain a filler solution;

[0021] S2: Prepare super-hydrophobic solution: mix filler solution and ...

Embodiment 3

[0030] A nano-superhydrophobic coating, the coating is composed of the following materials according to mass percentage: 180 parts of nano-silica, 120 parts of hexamethyldisilazane, 450 parts of solvent, 420 parts of silicone resin and 8 parts of curing agent , wherein the particle size of nano-silica is 40-60 nanometers, the curing agent is aliphatic polyamine, and the solvent is absolute ethanol, n-propanol, isopropanol, acetone, tetrahydrofuran, N, N-two A combination of one or more of methylacetamide or N,N-dimethylformamide, toluene and xylene.

[0031] A kind of production technique of nano superhydrophobic coating and, comprises the following steps:

[0032] S1: Preparation of filler solution: adding nano-silica and hexamethyldisilazane to the solvent to dilute, stirring ultrasonically for 20 minutes or high-speed ball milling for 120 minutes, and standing for 30 hours to obtain a filler solution;

[0033] S2: Prepare super-hydrophobic solution: mix filler solution and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com