Self-cleaning microwave absorption paint and uses thereof

A microwave absorption and self-cleaning technology, applied in radiation-absorbing coatings, epoxy coatings, polyurea/polyurethane coatings, etc., can solve the problem of polluted darkroom air environment, inability to use complex surface structure objects, without considering radio wave reflection and transmission and other problems, to achieve the effect of increasing surface roughness, low rolling angle, and superhydrophobic rolling angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

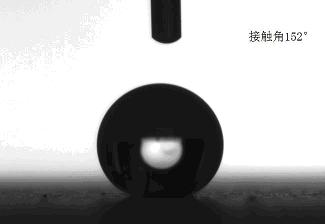

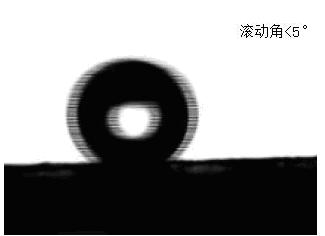

[0032] Weigh 20g of butyl acetate in a container, then add 20g of xylene, 1.6g of 10um ceramic microspheres and 0.4g of 30micron hollow glass microspheres in sequence, and disperse for 20-40min in a high-speed disperser under the condition of 100-300rpm. Uniform dispersion. Then add 6g of 20nm lipophilic silica, 4g of KH-550, adjust the rotation speed to 3000-5000rpm, and disperse for 30-90min. Add 6g of caking tree, 24g of acrylic acid resin, 20g of xylene, 0.03g of diisobutyltin dilaurate and 0.03g of triethylenediamine in turn, disperse at 400-600rpm for 20-40min, filter and spray with an air spray gun Based on the BPUFA050 and Pyramid absorbing materials, the self-cleaning absorbing material SCBPUFA050 is made. Use the SURFTENS Universal contact angle measuring instrument to measure the contact angle and rolling angle of SCBPUFA050 surface as figure 1 , figure 2 shown.

Embodiment 2

[0034] Weigh 40g of xylene in a container, then add 7g of 20nm lipophilic silica, 9g of KH-560, 1g of triethyl orthoformate, 11g of silicone resin DC840, 2g of epoxy resin E-21 resin, and adjust the speed gradually Increase to 3000-5000rpm, disperse for 30-90min to form a uniform dispersion. Then add 8g of binder resin, 13g of styrene-acrylic resin, 25g of xylene, 2.5g of Bayer N3390, 0.05g of diisobutyltin dilaurate and 0.05g of triethylenediamine, and disperse at 400-600rpm for 20-40min. After filtering impurities, use an air spray gun to spray on BPUFA100, BPUFA150, BPUFA200 pyramid absorbing materials to make SCBPUFA100, SCBPUFA150, SCBPUFA200 self-cleaning absorbing materials.

Embodiment 3

[0036] Weigh 40g of xylene into a container, then add 7.5g of 20nm lipophilic silica, 10g of KH-560, 1g of triethyl orthoformate, 5g of silicone resin DC840, 5g of bonding resin, and adjust the speed to 3000 At -5000rpm, disperse for 30-90min to form a uniform dispersion. Then add 10g of acrylic resin, 35g of xylene, 2.5g of alicyclic amine curing agent 5618, 0.05g of diisobutyltin dilaurate and 0.05g of triethanolamine, disperse at 400-600rpm for 20-40min, filter impurities and use The air spray gun is sprayed on the BPUFA300, BPUFA500, BPUFA700 pyramid absorbing materials to make self-cleaning absorbing materials SCBPUFA300, SCBUFA500, SCBPUFA700.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com