Composite material with self-cleaning function

A composite material, self-cleaning technology, applied in the field of new materials, can solve problems such as loss, damage to objects, and easy breeding of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

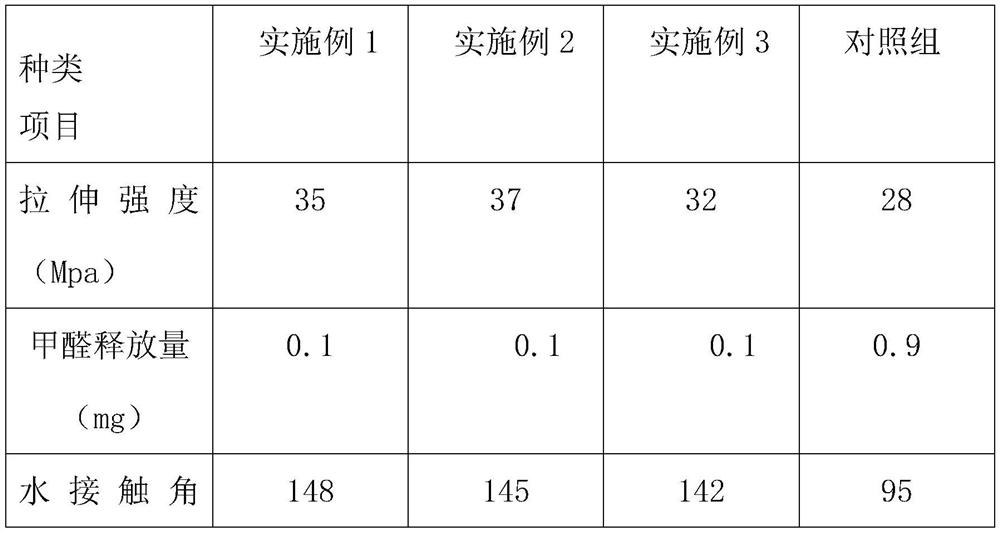

Examples

Embodiment 1

[0024] S1. Select 25 parts of epoxy resin and 32 parts of thermoplastic resin, then pour them into the mixer for stirring, start the mixer, control the internal temperature of the mixer at 210°C, and control the stirring time at 40 minutes to fully melt and mix , when stirring, the speed of the mixer is 150 rev / min, to obtain mixed resin;

[0025] S2. Then pour 13 parts of polydimethylsiloxane and 11 parts of polytetrafluoroethylene into the blender and preheat it. The preheating temperature is controlled at 60 ° C. Start stirring to mix it and heat it Evenly, the speed of the mixer is controlled at 30 rpm, and then after adding 9 parts of heat stabilizer, pour the mixed resin prepared in S1, at this time, adjust the temperature of the mixer to 220°C, and stir for 1.5 hours. All the raw materials added can be mixed evenly, and the speed of the mixer is controlled at 200 rpm to obtain a premix;

[0026] S3, add 6 parts of curing agent, 8 parts of silane, 12 parts of coupling a...

Embodiment 2

[0029] S1. Select 20 parts of epoxy resin and 25 parts of thermoplastic resin, then pour them into the mixer for stirring, start the mixer, control the internal temperature of the mixer at 180°C, and control the stirring time at 30 minutes to fully melt and mix , when stirring, the speed of the mixer is 140-160 rpm to obtain a mixed resin;

[0030] S2. Then pour 10 parts of polydimethylsiloxane and 8 parts of polytetrafluoroethylene into the blender, preheat it, and control the preheating temperature between 50°C, start stirring to mix it, so that it is heated evenly , the speed of the mixer is controlled at 15 / min, and then after adding 6 parts of heat stabilizer, pour the mixed resin prepared in S1, at this time, adjust the temperature of the mixer to 200°C and stir for 1 hour, so that the added The raw materials can be mixed evenly, and the speed of the mixer is controlled at 150 rpm to obtain a premix;

[0031] S3. Add 4 parts of curing agent, 6 parts of silane, 8 parts o...

Embodiment 3

[0034] S1. Select 30 parts of epoxy resin and 40 parts of thermoplastic resin, then pour them into the mixer for stirring, start the mixer, control the internal temperature of the mixer at 240°C, and control the stirring time at 50 minutes to fully melt and mix , while stirring,

[0035] The speed of mixer is 60 revs / min, obtains hybrid resin;

[0036] S2. Then pour 15 parts of polydimethylsiloxane and 14 parts of polytetrafluoroethylene into the blender and preheat it. The preheating temperature is controlled between 70 ° C. Start stirring to mix it and heat it Evenly, the speed of the mixer is controlled at 45 rpm, and then after adding 2 parts of heat stabilizer, pour the mixed resin prepared in S1, at this time, adjust the temperature of the mixer to 240°C, and stir for 2 hours. All the raw materials added can be mixed evenly, and the rotating speed of the mixer is controlled at 250 rpm to obtain a premix;

[0037] S3, add 8 parts of curing agent, 10 parts of silane, 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com