Universal preparation method for self-cleaning superhydrophobic paper

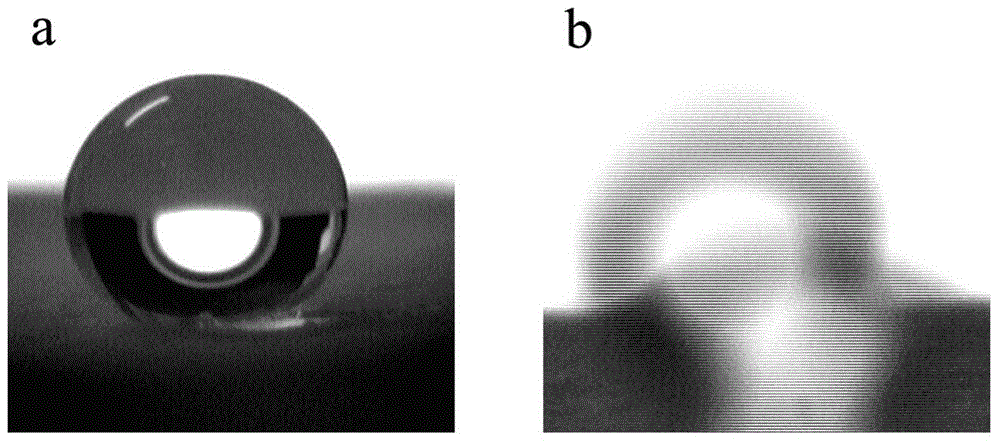

A super-hydrophobic, self-cleaning technology, applied in the field of bionic materials, can solve the problems of low surface energy materials such as high price, complex preparation process, and high adhesion, and achieve superior super-hydrophobic properties, simple preparation process, and low adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

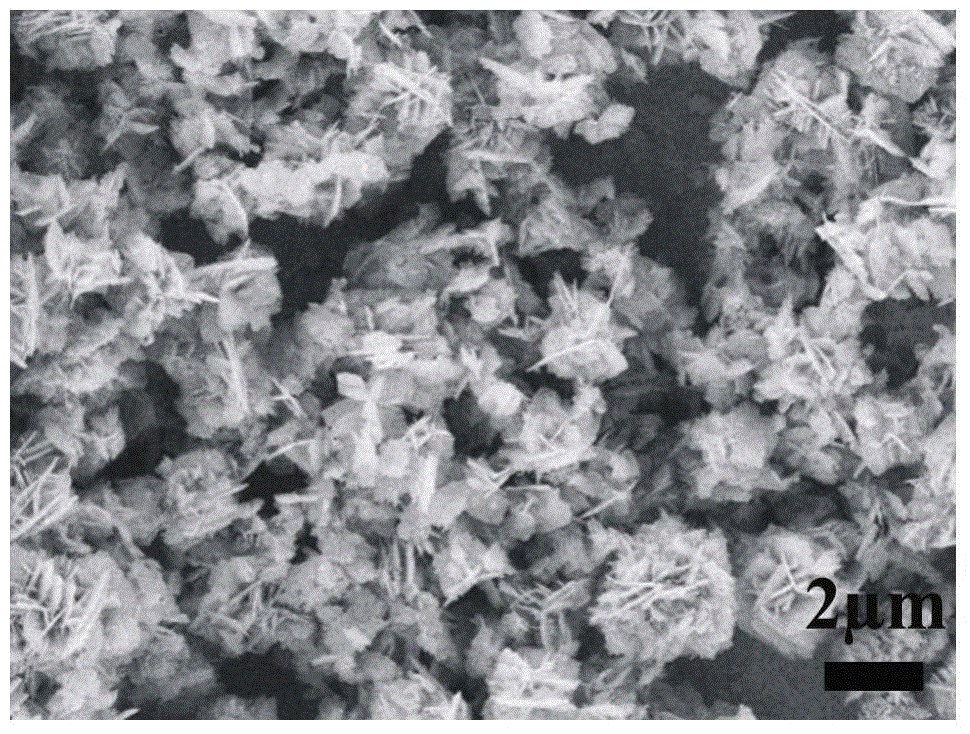

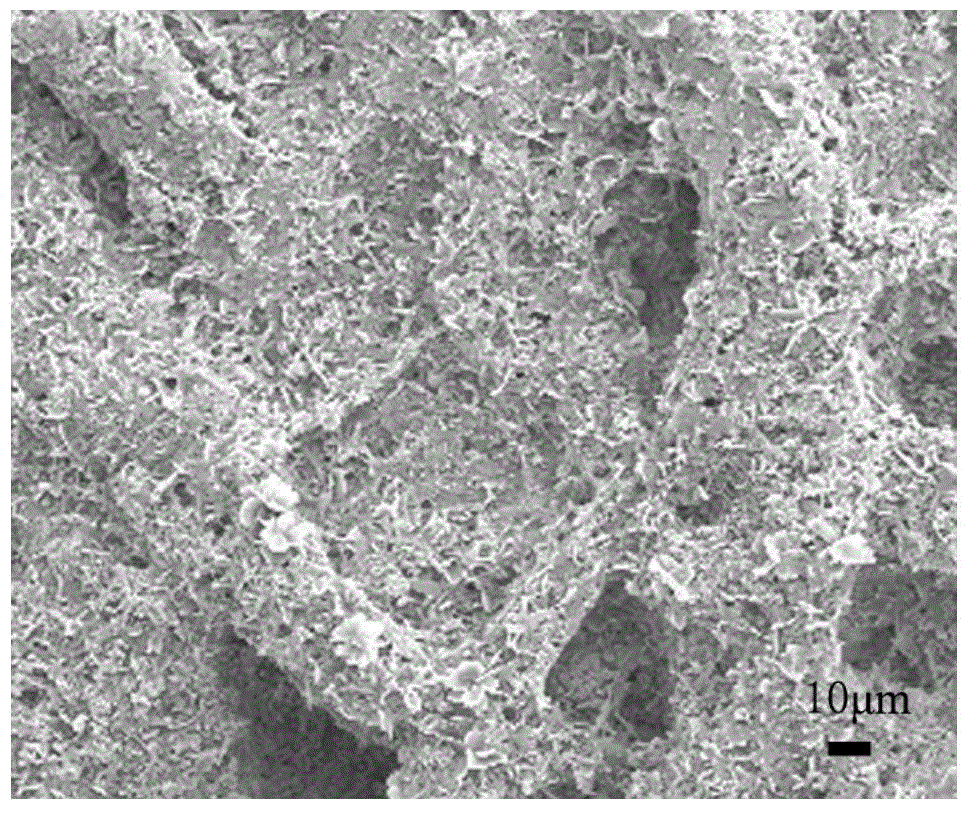

[0022] Weigh 0.1 g of ZnO powder with micro / nano hierarchical structure, disperse it in 30 mL of absolute ethanol, stir and sonicate to make it evenly mixed. Soak ordinary experimental filter paper (2cm×2cm) in the above suspension for 5 minutes, take it out and dry it in a blast drying oven at 100°C for 2 minutes, then put it into the suspension again for immersion treatment, and repeat this 8 times; according to the volume concentration Prepare an ethanol solution of stearic acid at a ratio of 5%, stir it at 80°C to dissolve it completely, then place the obtained filter paper in the stearic acid ethanol solution at 100°C for 30 minutes, take it out and dry it at 80°C for 6 hours to obtain self-cleaning Superhydrophobic filter paper products.

Embodiment 2

[0024] Weigh 0.1 g of ZnO powder with micro-nano hierarchical structure, disperse it in 15 mL of absolute ethanol, stir and sonicate to make it evenly mixed. Soak ordinary printing paper (2cm×2cm in size) in the above suspension for 10min, take it out and dry it in an air-blast drying oven at 80°C for 5min, and repeat it 4 times; prepare a toluene solution with a volume concentration of 3% stearic acid, The obtained filter paper was placed in the stearic acid toluene solution at 60°C for 3 hours, then taken out and dried at 80°C for 6 hours, and a self-cleaning superhydrophobic filter paper product was also obtained.

Embodiment 3

[0026] Adopt the same operating steps as in Example 1 to carry out the deposition of micro-nano hierarchical structure ZnO on the paper surface, and in the subsequent low surface energy substance treatment, use n-dodecane solution of stearic acid to replace the stearic acid in Example 1 Ethanol solution, the rest of the operating steps are the same as in Example 1, and can also be obtained from cleaning superhydrophobic filter paper products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com