Cone-shaped Janus particle, preparation method and application thereof

A particle and cone-shaped technology, applied in the field of cone-shaped Janus particles and their preparation, can solve the problems of lack of synthetic exploration, few structural studies, and single formation process of Janus properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] Wherein, the preparation method of described superhydrophobic surface material comprises the steps:

[0088] 1) Apply the conical Janus particles to the surface of the substrate, and solidify at a certain temperature, for a certain period of time, and in the presence of a curing agent;

[0089] 2) Remove uncured conical Janus particles with a poor solvent.

[0090] In the curing reaction step, the temperature is 20-80°C; the time is 2-12 hours; the curing agent is one or more of acid anhydride, imidazole, polyamine, polythiol, and polyphenol; The poor solvent is at least one selected from water, petroleum ether, ethanol and alkanes with 4-10 carbon atoms.

Embodiment 1

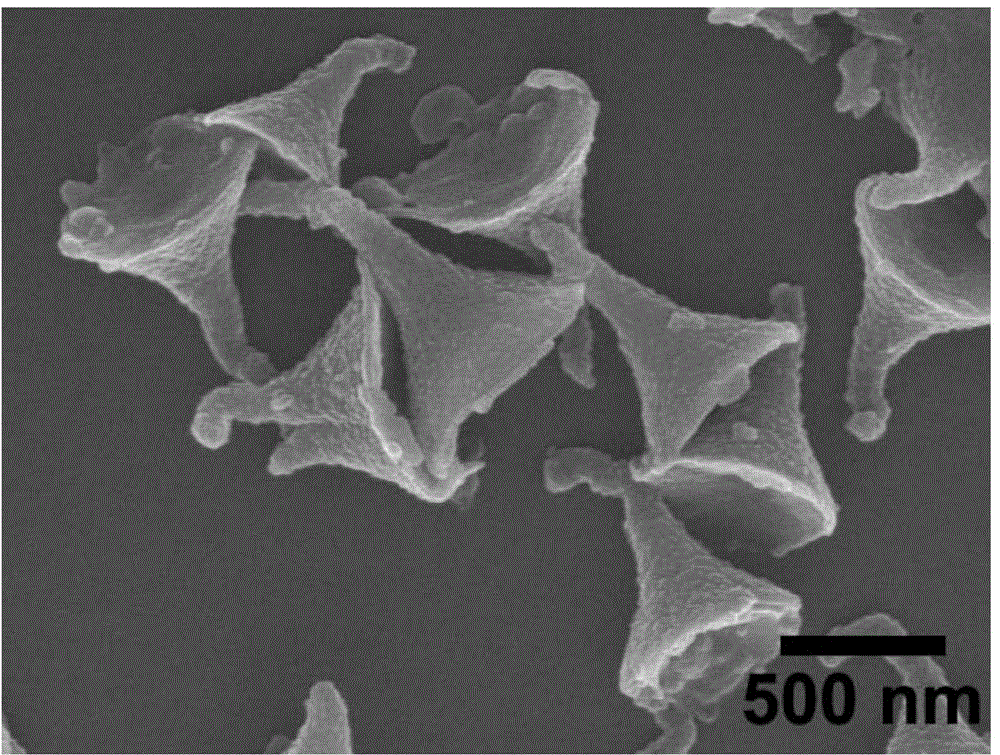

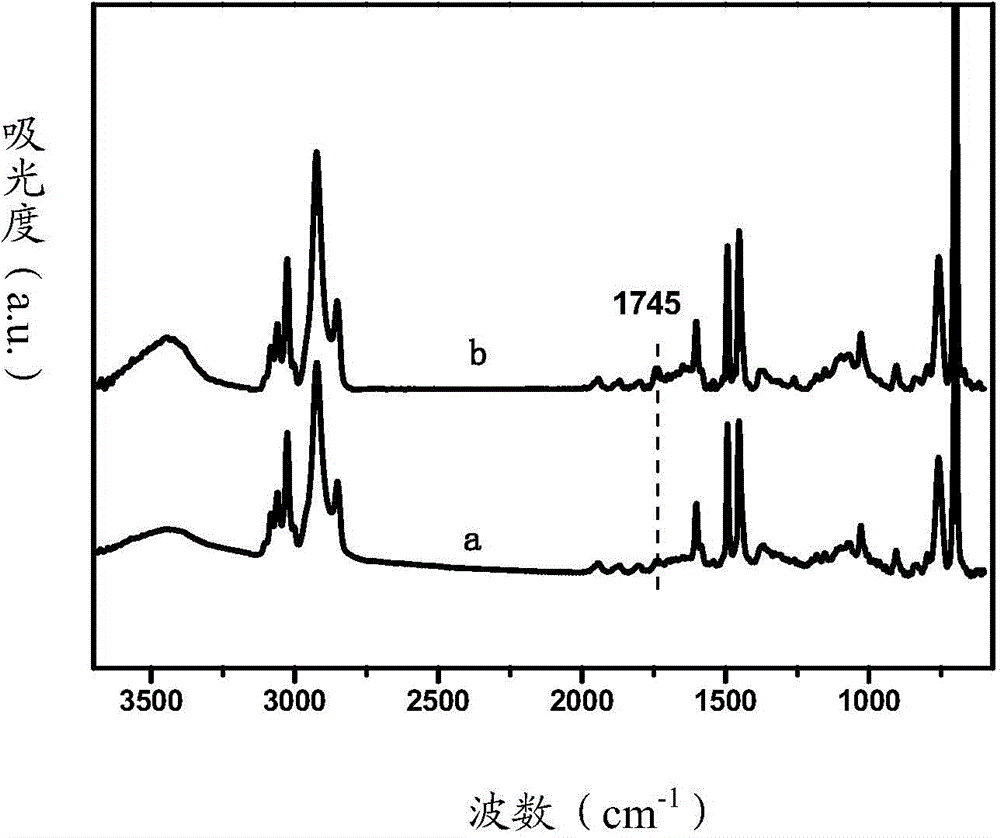

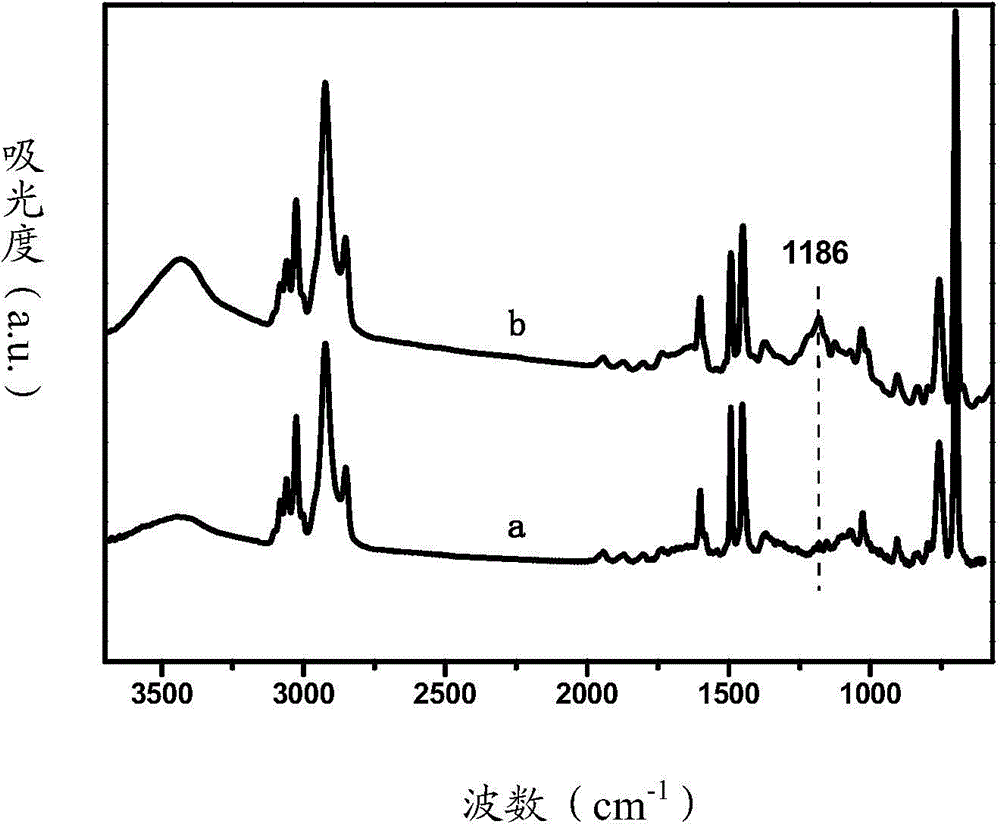

[0094] [Example 1] Preparation of tapered Janus nanoparticles grafted with acrylamide

[0095] In this example, sodium lauryl sulfate and sorbitan monooleate are used as emulsifiers, and a phase change product with a specification of 52-54°C (melting point of 52-54°C) purchased from Sinopharm Chemical Reagent Co., Ltd. is used. Paraffin was used as the oil phase material.

[0096] 0.35 g of sodium lauryl sulfate and 0.5 g of sorbitan monooleate were added to 85 g of water, and this solution was used as the water phase.

[0097]Mix 10g of phase-change paraffin wax with a specification of 52-54°C, 2g of styrene, 1g of divinylbenzene, and 0.06g of azobisisobutyronitrile as an initiator, raise the temperature to 60°C, and stir to make them evenly mixed as an oil phase .

[0098] The above-mentioned water phase and oil phase were mixed, heated to 60°C, and sheared and emulsified for 2 minutes at a speed of 12,000 rpm using a high-speed mixer to obtain an oil-in-water emulsion.

...

Embodiment 2

[0102] [Example 2] Preparation of conical Janus nanoparticles composited by ferroferric oxide

[0103] 1. Preparation of Conical Nanoparticles

[0104] Sorbitan monooleate and polyoxyethylene ether sorbitan monooleate were used as emulsifiers, and phase-change paraffin wax with a specification of 52-54°C purchased from Sinopharm Chemical Reagent Co., Ltd. was used as an oil phase material.

[0105] 1 g of sorbitan monooleate and 0.5 g of polyoxyethylene ether sorbitan monooleate were added to 85 g of water, and this solution was used as the water phase.

[0106] Mix 10 g of phase-change paraffin, 2 g of styrene, 1 g of divinylbenzene, and 0.06 g of azobisisobutyronitrile as an initiator, raise the temperature to 60° C., and stir to mix them uniformly to form an oil phase.

[0107] The above-mentioned water phase and oil phase were mixed, heated to 60°C, and sheared and emulsified for 2 minutes at a speed of 12,000 rpm using a high-speed mixer to obtain an oil-in-water emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com