Method for preparing super-hydrophobic surface with micro-nano needle protrusions through microwaves

A super-hydrophobic surface and micro-nano technology, applied in the field of super-hydrophobic, can solve the problems of limited application, difficulty in direct metal deposition, high cost, etc., achieve good reusability and avoid cumbersome operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

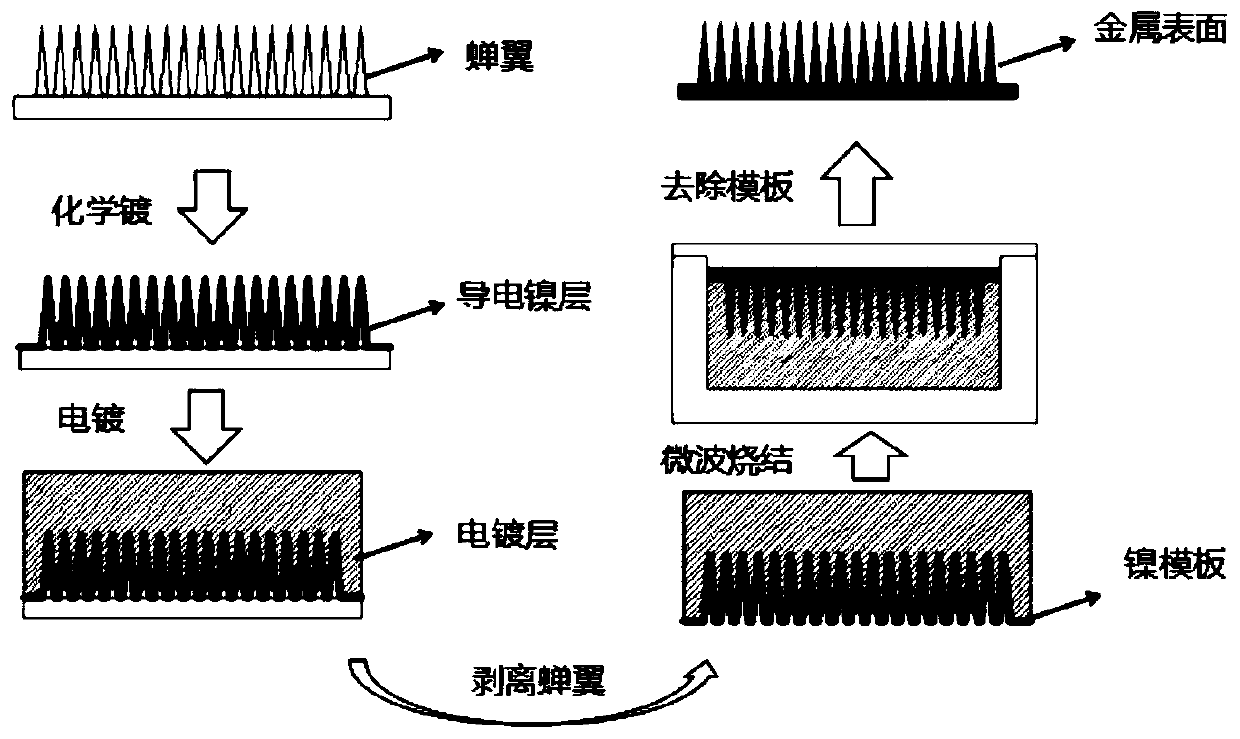

[0031] Step 1: Rinse the cicada wings with deionized water for 20 minutes, then ultrasonically clean them with acetone for 20 minutes, and finally, ultrasonically clean them with deionized water for 10 minutes to remove residual acetone, and then dry them in a vacuum oven at 40°C.

[0032] Step 2, the cicada wings after step 1 cleaning and drying are first at 25 DEG C in the sensitizing solution (the composition of the sensitizing solution is 10g / L SnCl 2 ·H 2 O, 40ml / L HCl, 1g / L C 12 h 25 SO 4 Soak in Na) for 10min, then at 25°C in the activation solution (the composition of the activation solution is 1g / L PdCl 2 ·H 2 (0, 10ml / L HCl) for 5min. During the sensitization process, sodium dodecylsulfonate (C 12 h 25 SO 4 Na) as a surfactant to improve hydrogenation performance. Then, the cicada wings are naturally dried in the air to obtain the pretreated cicada wings.

[0033] Step 3, adopt chemical plating to fix the natural cicada wing after step 2 pretreatment on the...

Embodiment 2

[0037] Step 1, step 2 and step 3 are the same as embodiment 1.

[0038] Step 4, the nickel replica prepared in step 3 is used as a template, and the surface of the template is filled with ultrafine metal powder (zinc particle size is 300 mesh) after ball milling and compacted. Under the condition of microwave heating, the template filled with metal powder is heated to a temperature of 1200°C, kept for 1h, the microwave frequency is 10.5GHz, and the output power of the microwave source is 2kW. After cooling, the nickel template is removed to obtain a zinc metal surface with micro-nano needle protrusions. .

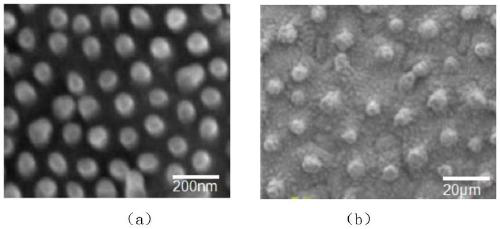

[0039] The average diameter of the micro-nano needle-convex structure on the metal replica prepared by the above steps is about 152 nm, and the average pitch is about 220 nm. The water contact angle of the metal replica surface in the wavelength range of 400-1000nm is 158°±2°, and the reflectance is about 4%.

Embodiment 3

[0041] Step 1 and step 2, with embodiment 1.

[0042] Step 3, adopt chemical plating to fix the natural cicada wing after step 2 pretreatment on the support glass, then immerse in chemical nickel plating solution (the composition of chemical nickel plating solution is 30g / L NiSO 4 ·6H 2 O, 30g / L NaH 2 PO 2 ·H 2 O, 20g / LNa 3 C 6 h 5 o 7 2H 2 (0), adjust the pH value of the solution to 8.5 with ammonia water, and stir magnetically at 40°C and 150r / min. A conductive nickel layer is deposited on the surface of the natural cicada wing by the above chemical plating. Subsequently, electroplating was carried out at 50°C with the conductive nickel-covered flap as the cathode and the Ni-S plate as the anode (the composition of the electroplating solution was 300g / L Ni(SO 3 NH 2 ) 2 4H 2 O, 15g / L NiCl 2 ·6H 2 O, 20g / L H 3 BO 3 ), the constant current density is 3A / dm 2 . In order to ensure the homogeneity of the electrolyte solution, magnetic stirring at a rotational s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com