MOF compounded copper-based nanorod array@foam copper based composite electrode material, preparation method and application thereof

A nanorod array and composite electrode technology, applied in the direction of electrodes, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor catalytic activity and stability, achieve good stability, improve stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

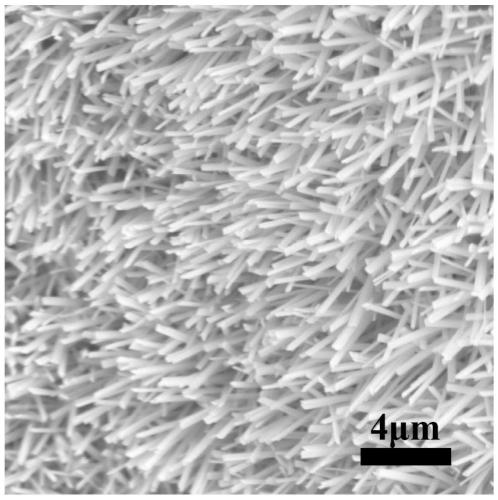

[0031] The preparation of a MOF composite copper-based nanorod array@foamed copper-based composite electrode material comprises the following steps:

[0032] a. Pretreatment of foamed copper: Take foamed copper, cut it into 1cm×2cm size, put it in a beaker, add absolute ethanol to submerge, pour out absolute ethanol after ultrasonication for 15min, add 1mol / L dilute hydrochloric acid until submerged After 15 minutes of ultrasonication, rinse with water and set aside.

[0033] b. First, prepare the precursor solution: measure 30mL of deionized water and put it in a beaker, then add 1.64g (7.2mmol) of ammonium persulfate, stir and sonicate for 15min, and wait until it is completely dissolved; measure 30mL of deionized water and place In a beaker, add 10.1 g (180 mmol) of potassium hydroxide, stir and sonicate for 15 min until completely dissolved, then add ammonium persulfate solution, and stir evenly to obtain the precursor solution. Then, in the precursor solution, add the co...

Embodiment 2

[0038] The preparation of a MOF composite copper-based nanorod array@foamed copper-based composite electrode material comprises the following steps:

[0039] a. Pretreatment of foamed copper: Take foamed copper, cut it into 1cm×2cm size, put it in a beaker, add absolute ethanol to submerge, pour out absolute ethanol after ultrasonication for 15min, add 1mol / L dilute hydrochloric acid until submerged , after 20 minutes of ultrasonication, rinse with water and set aside.

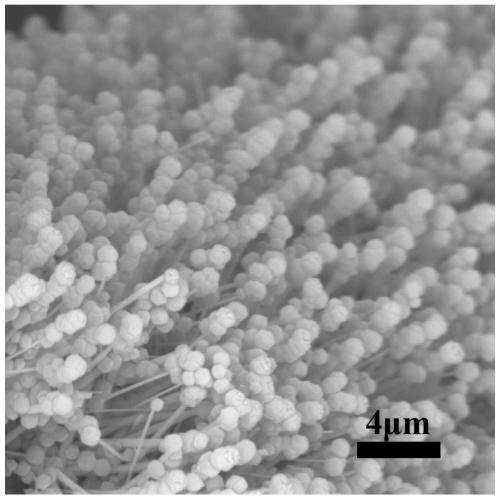

[0040] b. First, prepare the precursor solution: measure 30mL of deionized water and put it in a beaker, then add 1.64g (7.2mmol) of ammonium persulfate, stir and sonicate for 15min, and wait until it is completely dissolved; measure 30mL of deionized water and place In the beaker, then add 20.2 g (360 mmol) of potassium hydroxide, stir and sonicate for 15 min, until it is completely dissolved, add ammonium persulfate solution, and stir evenly to obtain the precursor solution. Then, add the copper foam treate...

Embodiment 3

[0044] The preparation of a MOF composite copper-based nanorod array@foamed copper-based composite electrode material comprises the following steps:

[0045] a. Pretreatment of foamed copper: Take foamed copper, cut it into 1cm×2cm size, put it in a beaker, add absolute ethanol to submerge, pour out absolute ethanol after ultrasonication for 15min, add 1mol / L dilute hydrochloric acid until submerged , after 20 minutes of ultrasonication, rinse with water and set aside.

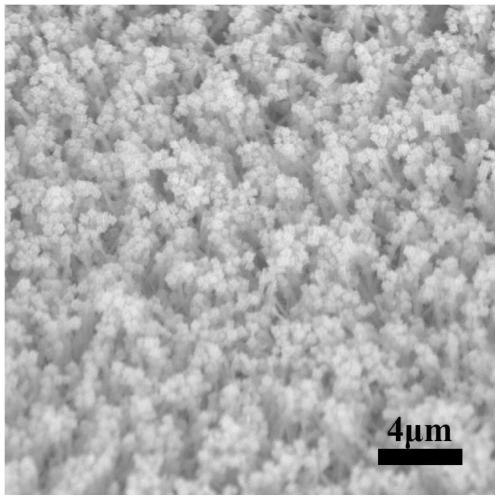

[0046] b. First, prepare the precursor solution: measure 30mL of deionized water and put it in a beaker, then add 1.64g (7.2mmol) of ammonium persulfate, stir and sonicate for 15min, and wait until it is completely dissolved; measure 30mL of deionized water and place In the beaker, then add 20.2 g (360 mmol) of potassium hydroxide, stir and sonicate for 15 min, until it is completely dissolved, add ammonium persulfate solution, and stir evenly to obtain the precursor solution. Then, in the precursor solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com