A kind of preparation method of superhydrophobic PVDF film

A superhydrophobic and hydrophobic technology, which is applied in the field of superhydrophobic PVDF membrane preparation, can solve membrane wetting and other problems, achieve the effect of alleviating membrane wetting and improving anti-wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

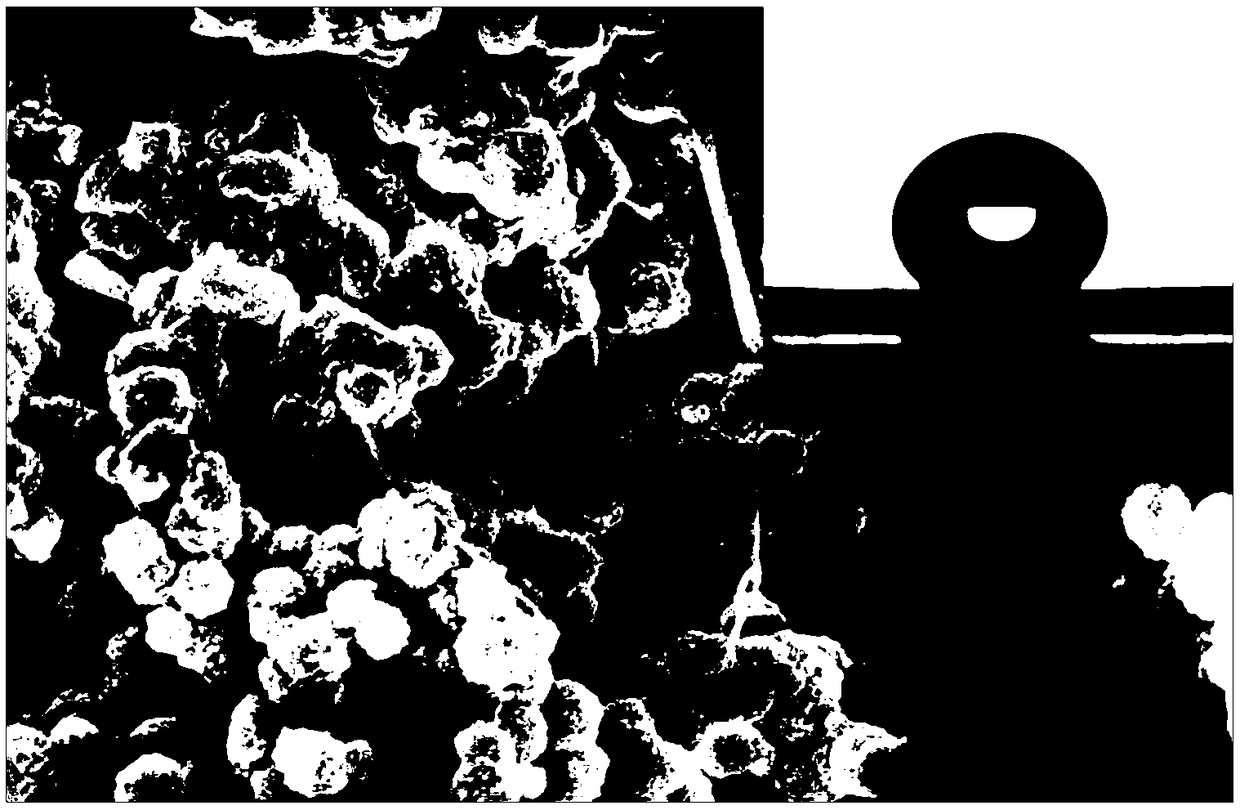

Image

Examples

Embodiment 1

[0025] Take 8.6ml polyethylene glycol-400 and add it to 153ml N-methylpyrrolidone, make it mix well. Then add 36g of PVDF to the above solution while stirring, stir for 12 hours under the condition of constant temperature heating in a water bath at 60°C to dissolve it completely, and leave it in a vacuum oven at 40°C for 12 hours to obtain a uniform casting solution after degassing; weigh 1g of graphite Add olefin to 1000ml methanol, disperse evenly and add 2000ml deionized water to make a coagulation bath. Use a scraper to scrape the casting solution on a glass plate to prepare a nascent flat film, stay in the air for 30s, and then place the nascent flat film in the coagulation bath prepared above until it solidifies into a PVDF film; put the film in deionized water Soak for 24 hours, thoroughly remove the residual solvent in the membrane, and dry at room temperature to obtain the superhydrophobic PVDF membrane. The PVDF membrane prepared in Example 1 was tested and found th...

Embodiment 2

[0027] Take 9.2ml polyethylene glycol-600 and add it to 165ml N,N-dimethylformamide, make it mix well. Then add 40g of PVDF into the above solution while stirring, stir for 12h under the condition of constant temperature heating in a water bath at 60°C to dissolve it completely, and leave it in a vacuum oven at 40°C for 12h to obtain a uniform casting solution after defoaming; weigh 1g of alkane TiO 2 The nanoparticles were added into 1000ml of absolute ethanol, dispersed evenly, and then added into 1000ml of deionized water to prepare a coagulation bath. Use a scraper to scrape the casting solution on a glass plate to prepare a nascent flat film, stay in the air for 30s, and then place the nascent flat film in the coagulation bath prepared above until it solidifies into a PVDF film; put the film in deionized water Soak for 24 hours, thoroughly remove the residual solvent in the membrane, and dry at room temperature to obtain the superhydrophobic PVDF membrane. The PVDF memb...

Embodiment 3

[0029] Take 8.6ml polyethylene glycol-400 and add it to 153ml N-methylpyrrolidone, make it mix well. Then add 36g of PVDF to the above solution while stirring, stir for 12 hours under the condition of constant temperature heating in a water bath at 60°C to dissolve it completely, and leave it in a vacuum oven at 40°C for 12 hours to obtain a uniform casting solution after degassing; weigh 1g of fluorine SiO 2 The nanoparticles were added into 1000ml of N-methylpyrrolidone, dispersed uniformly and then added into 1000ml of deionized water to prepare a coagulation bath. Use a scraper to scrape the casting solution on a glass plate to prepare a nascent flat film, stay in the air for 30s, and then place the nascent flat film in the coagulation bath prepared above until it solidifies into a PVDF film; put the film in deionized water Soak for 24 hours, thoroughly remove the residual solvent in the membrane, and dry at room temperature to obtain the superhydrophobic PVDF membrane. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com