A kind of intrinsic superhydrophobic ceramic coating and preparation method thereof

A ceramic coating and super-hydrophobic technology, which is applied in the coating, metal material coating process, superimposed layer plating, etc., can solve the problem of low service life of super-hydrophobic surface, and achieve the effect of high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of intrinsic superhydrophobic ceramic coating of the present invention is as follows:

[0027] The first step is to use Ti6Al4V titanium alloy as the base material, and use wire cutting to process the base material into a size of 15mm×15mm×3mm, and use No. 1 to No. 6 metallographic sandpaper to polish the surface of the base material until there is no scratch under the naked eye. Then it was mechanically polished until there were no obvious scratches under the metallographic microscope, and it was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 10 minutes, and dried for use;

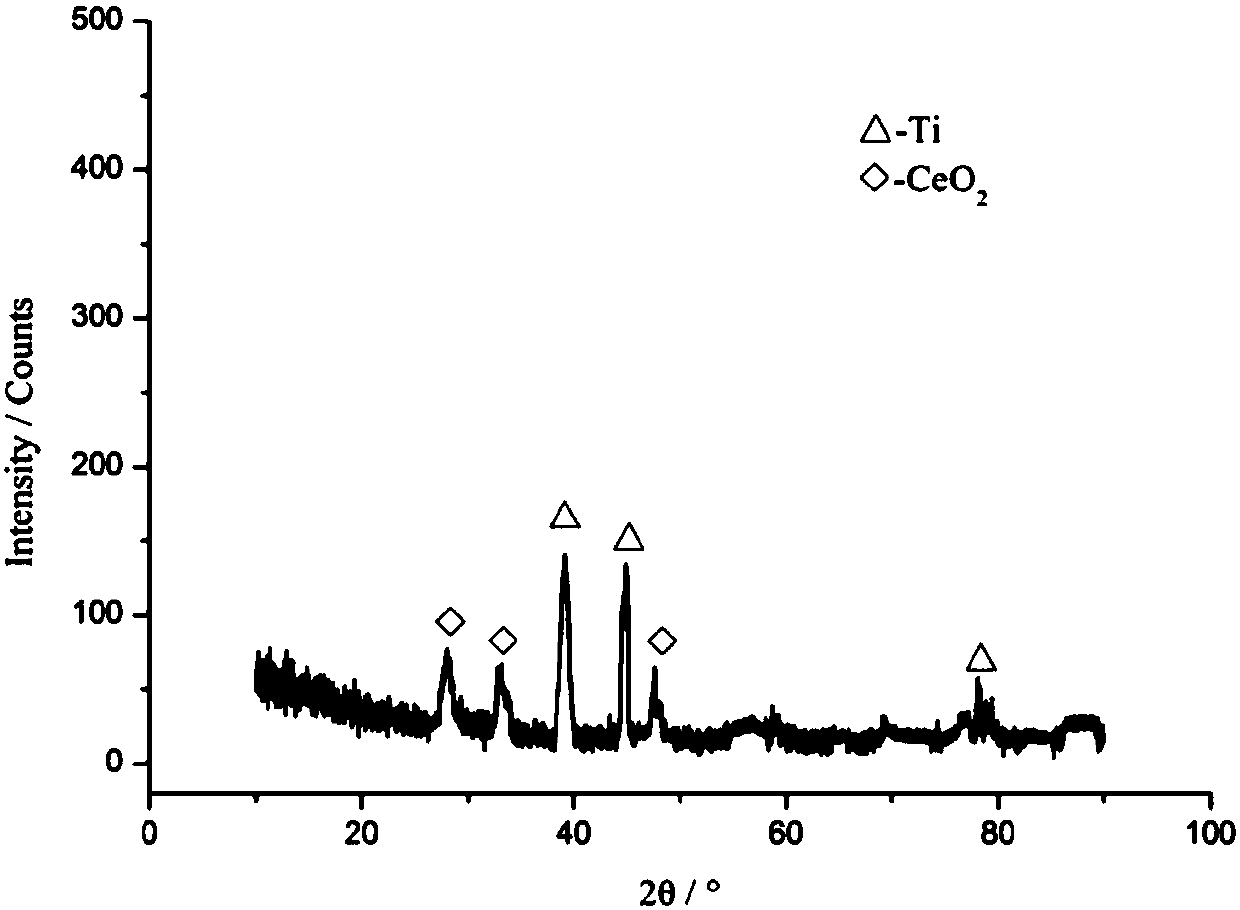

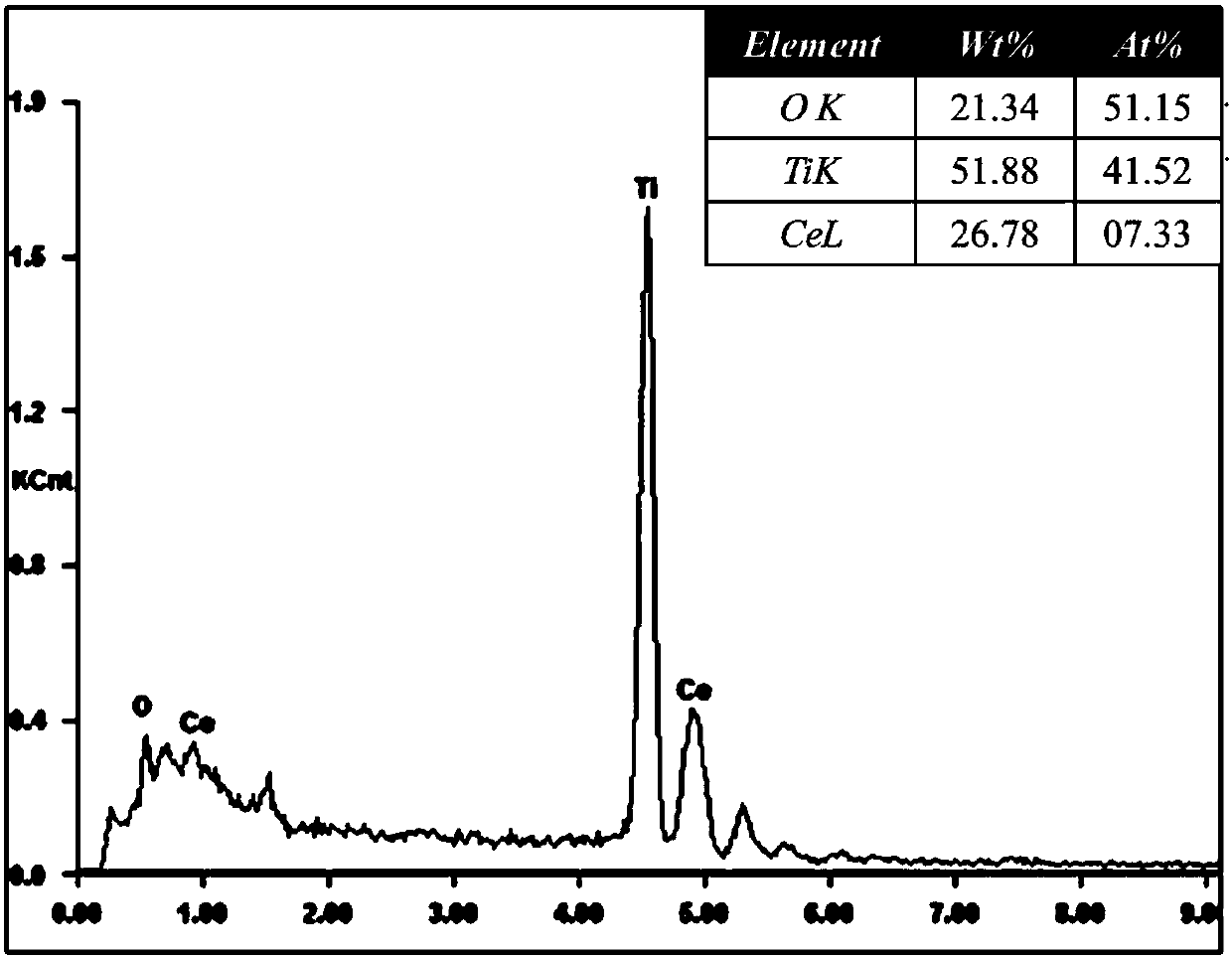

[0028] In the second step, high-purity (99.99%) metal cerium is used as the target material, and the target material is placed at the source in the double-glow plasma infiltration furnace, and the Ti6Al4V titanium alloy is placed at the workpiece electrode, and the Ar pressure is controlled to 40MPa , The source voltage is 600V, t...

Embodiment 2

[0032] The preparation method of intrinsic superhydrophobic ceramic coating of the present invention is as follows:

[0033] The first step is to use 316L stainless steel as the base material, and use wire cutting to process the base material into a size of 15mm×15mm×3mm, and use metallographic sandpaper No. 1 to 6 to polish the surface of the base material until there is no scratch under the naked eye, and then Mechanically polish it until there are no obvious scratches under the metallographic microscope, and ultrasonically clean it in deionized water, acetone, absolute ethanol and deionized water for 10 minutes, and dry it for use;

[0034] In the second step, using high-purity (99.99%) metal cerium as the target, the target is placed at the source in the double-glow plasma infiltration furnace, and 316L stainless steel is placed at the electrode of the workpiece, and the Ar pressure is controlled to 40MPa, The source voltage is 650V, the workpiece voltage is 300V, the pole...

Embodiment 3

[0038] The preparation method of intrinsic superhydrophobic ceramic coating of the present invention is as follows:

[0039] The first step is to use Ti6Al4V titanium alloy as the base material, and use wire cutting to process the base material into a size of 15mm×15mm×3mm, and use No. 1 to No. 6 metallographic sandpaper to polish the surface of the base material until there is no scratch under the naked eye. Then it was mechanically polished until there were no obvious scratches under the metallographic microscope, and it was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 10 minutes, and dried for use;

[0040]In the second step, using high-purity (99.99%) metal erbium as the target material, the target material is placed at the source in the double-glow plasma infiltration furnace, and the Ti6Al4V titanium alloy is placed at the workpiece electrode, and the Ar pressure is controlled to 35MPa , The source voltage is 800V, the work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface free energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com