Preparation method of super-hydrophobic coating based on polydopamine self-assembly

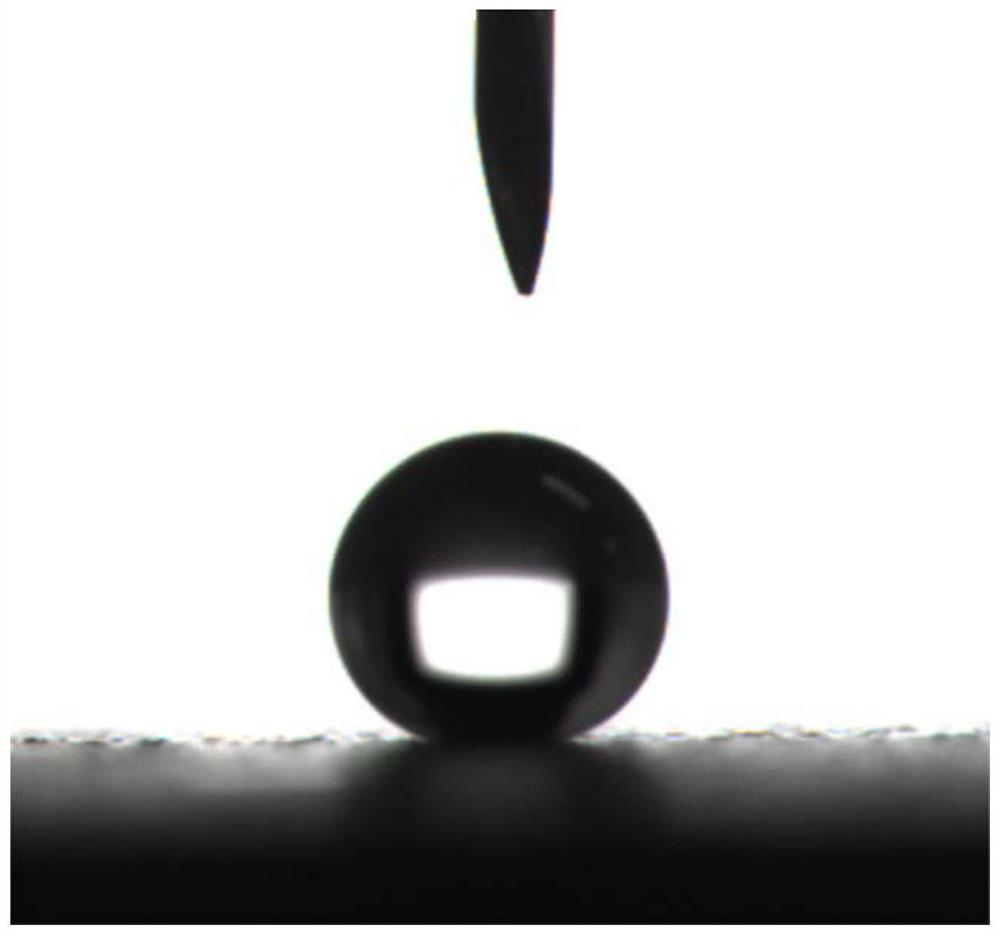

A technology of super-hydrophobic coating and polydopamine, which is applied in coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc. It can solve the problems of poor oxidizing agent and hydrophobic modification effect, achieve good chemical stability and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The concrete steps of the preparation method of superhydrophobic coating in the present embodiment are as follows:

[0026] (1) Ultrasonic degrease the glass slides in ethanol for 30 minutes, wash them three times with deionized water, and then place them in a blast oven at 80°C for 2 hours to dry for later use.

[0027] (2) Weigh 6.057g of Tris in a beaker, add an appropriate amount of ultrapure water to dissolve it, transfer it to a 1L volumetric flask, and adjust the pH to 8.5 with hydrochloric acid to obtain Tris-hydrochloric acid buffer.

[0028] (3) Take by weighing 0.1g dopamine hydrochloride and 0.014g nanometer zero-valent iron in a 100mL beaker, add 50mL of tris-hydrochloric acid buffer solution prepared by step (2), and magnetically stir it to fully dissolve it to obtain mixture.

[0029] (4) Immerse the glass slide in the mixed solution obtained in step (3) for deposition for 4 hours, accompanied by magnetic stirring at the stirring speed of 200r·min -1 ,...

Embodiment 2

[0034] The concrete steps of the preparation method of superhydrophobic coating in the present embodiment are as follows:

[0035] (1) Ultrasonic degrease the glass slides in ethanol for 30 minutes, wash them three times with deionized water, and then place them in a blast oven at 80°C for 2 hours to dry for later use.

[0036] (2) Weigh 6.057g of Tris in a beaker, add an appropriate amount of ultrapure water to dissolve it, transfer it to a 1L volumetric flask, and adjust the pH to 8.5 with hydrochloric acid to obtain Tris-hydrochloric acid buffer.

[0037] (3) Take by weighing 0.1g dopamine hydrochloride, 0.014g nanometer zero-valent iron in a 100mL beaker, add 50mL of tris-hydrochloric acid buffer solution prepared by step (2), and magnetically stir it to fully dissolve it to obtain mixture.

[0038] (4) Immerse the glass slide in the mixed solution obtained in step (3) for deposition for 1 h, accompanied by magnetic stirring at a stirring speed of 100 r min -1 , take ou...

Embodiment 3

[0043] The concrete steps of the preparation method of superhydrophobic coating in the present embodiment are as follows:

[0044] (1) Ultrasonic degrease the glass slides in ethanol for 30 minutes, wash them three times with deionized water, and then place them in a blast oven at 80°C for 2 hours to dry for later use.

[0045] (2) Weigh 6.057g of Tris in a beaker, add an appropriate amount of ultrapure water to dissolve it, transfer it to a 1L volumetric flask, and adjust the pH to 8.5 with hydrochloric acid to obtain Tris-hydrochloric acid buffer.

[0046] (3) Take by weighing 0.1g dopamine hydrochloride, 0.014g nanometer zero-valent iron in a 100mL beaker, add 50mL of tris-hydrochloric acid buffer solution prepared by step (2), and magnetically stir it to fully dissolve it to obtain mixture.

[0047](4) Immerse the glass slide in the mixed solution obtained in step (3) for deposition for 4 hours, accompanied by magnetic stirring at the stirring speed of 180r min -1 , tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com