Method for inducing polymer to graft carbon nano tube in mixed solvent for self-assembly

A technology of carbon nanotubes and mixed induction, which is applied in the direction of carbon compounds, nanotechnology, nanotechnology, etc., can solve the problem of not reflecting the characteristics of one-dimensional materials, and achieve the effect of regular shape and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

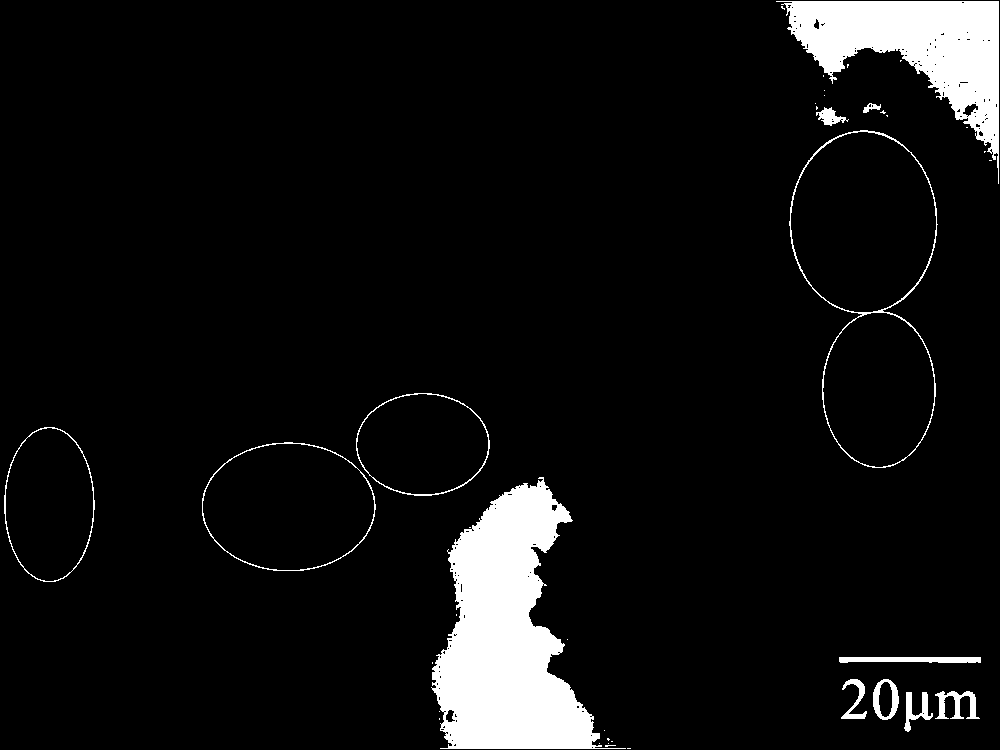

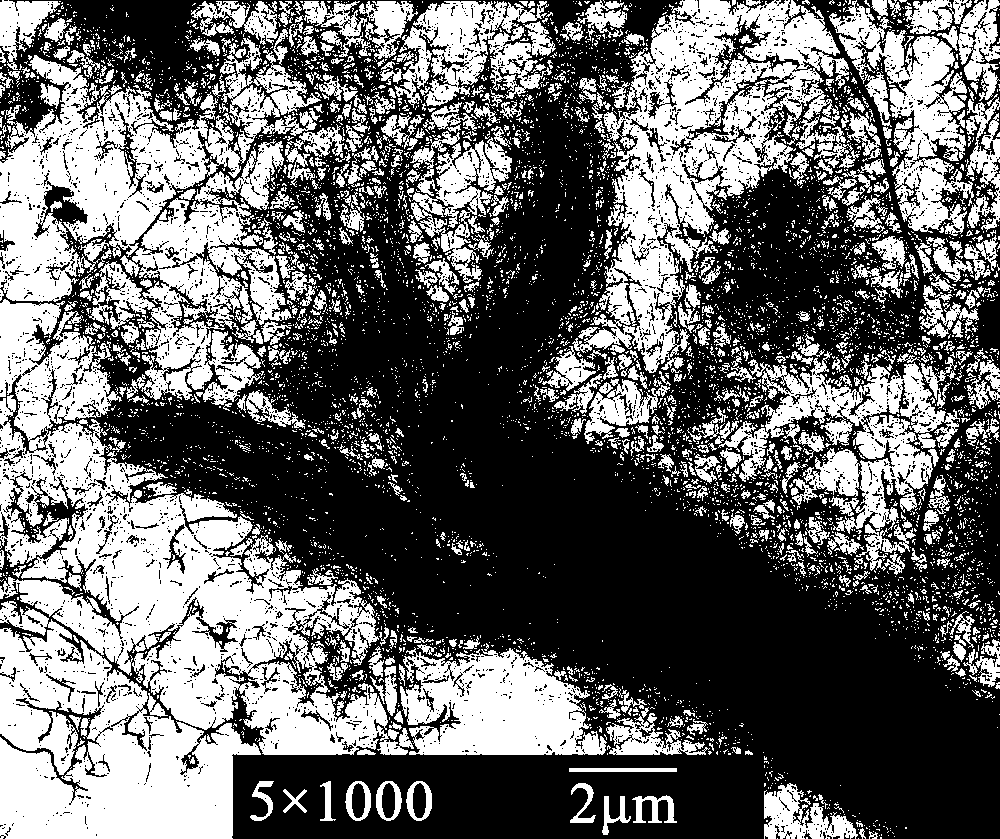

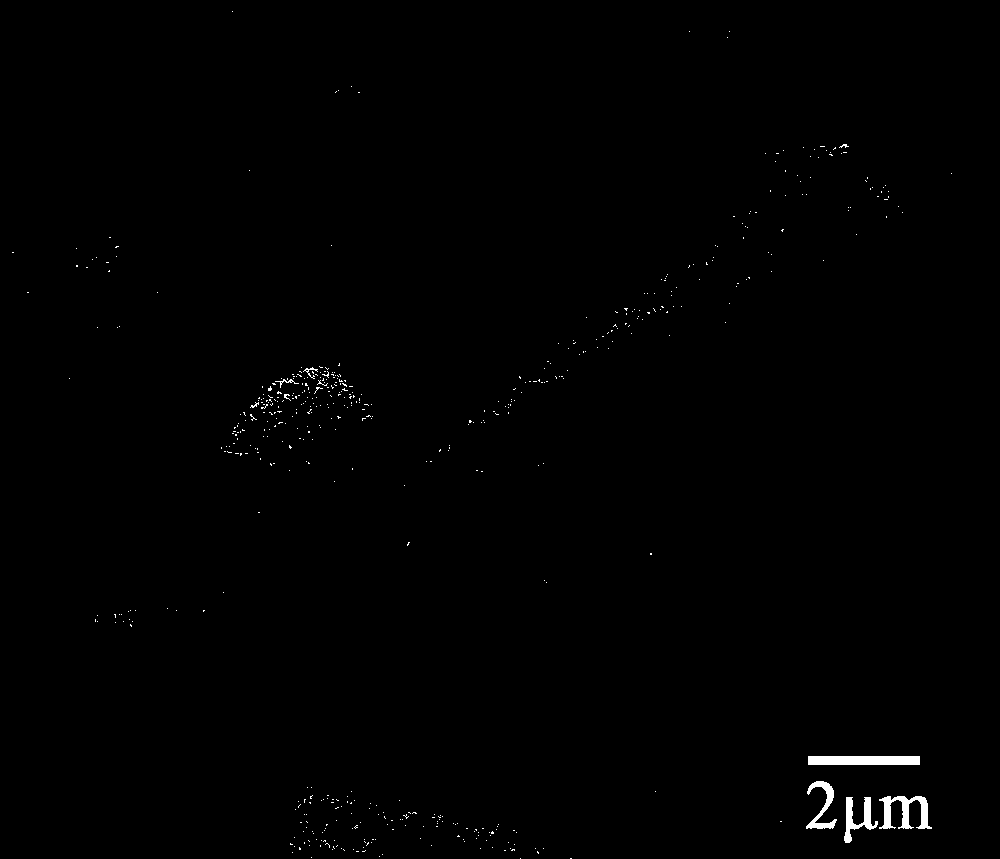

[0022] Example 1: Disperse carbon nanotubes grafted with polystyrene into tetrahydrofuran by ultrasonic waves at a concentration of 0.05 mg / ml. While magnetically stirring, drop ethanol into the dispersion system and let it stand for 10 minutes. The self-assembled carbon nanotubes with a diameter of 0.5-1 μm were collected.

[0023] Step (1): Add 1mg of polystyrene-grafted carbon nanotubes into 20ml of tetrahydrofuran, the degree of polymerization of polystyrene is 200, the grafting rate of carbon nanotubes is 45%, and the length of carbon nanotubes is 15-20 μm. Ultrasonic dispersion for 15 minutes;

[0024] Step (2): While stirring magnetically at a speed of 100 r / min, 0.5 ml of ethanol was added dropwise. After the ethanol was added dropwise, stop the magnetic stirring and let it stand for 10 minutes. A self-assembly of carbon nanotubes with a length of 15-20 μm and a diameter of 0.5-1 μm can be collected at the bottom of the container.

Embodiment 2

[0025] Example 2: Disperse the carbon nanotubes grafted with polystyrene into dichlorobenzene by ultrasonic waves, the concentration is 0.2mg / ml, while stirring magnetically, drop benzene into the dispersion system, let it stand for 15 minutes, and it can be Self-assembled carbon nanotubes with a diameter of 2-4 μm were collected at the bottom of the container.

[0026] Step (1): Add 2mg polystyrene-grafted carbon nanotubes into 10ml dichlorobenzene, the degree of polymerization of polystyrene is 250, the grafting rate of carbon nanotubes is 45%, and the length of carbon nanotubes is 15~ 20μm, ultrasonic dispersion for 15 minutes;

[0027] Step (2): While stirring magnetically at a speed of 100 r / min, 5 ml of benzene was added dropwise. After the benzene is added dropwise, stop the magnetic stirring and let it stand for 15 minutes. A self-assembly of carbon nanotubes with a length of 15-20 μm and a diameter of 2-4 μm can be collected at the bottom of the container.

Embodiment 3

[0028] Example 3: Disperse polyacrylamide-grafted carbon nanotubes into deionized water by ultrasonic waves at a concentration of 0.3 mg / ml. While stirring magnetically, drop methanol into the dispersion system and let it stand for 20 minutes. The self-assembled carbon nanotubes with a diameter of 1.5-2.5 μm were collected.

[0029] Step (1): Disperse 6 mg of carbon nanotubes grafted with polyacrylamide into 20 ml of deionized water by ultrasonic waves. The degree of polymerization of polyacrylamide is 220, the grafting rate of carbon nanotubes is 40%, and the length of carbon nanotubes is 15~20μm, ultrasonic dispersion for 15 minutes;

[0030] Step (2): While stirring magnetically at a speed of 100 r / min, add 5 ml of methanol dropwise. After the methanol was added dropwise, stop the magnetic stirring and let it stand for 20 minutes. A self-assembly of carbon nanotubes with a length of 15-20 μm and a diameter of 1.5-2.5 μm can be collected at the bottom of the container.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com