Coral sand breathable impermeable sand

A technology of coral sand and anti-seepage sand, applied in the field of composite materials, can solve problems such as inability to make full use of coral sand resources, and achieve the effect of solving the problem of the source of vegetables and fruits, and solving the problem of fresh water drinking and drinking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

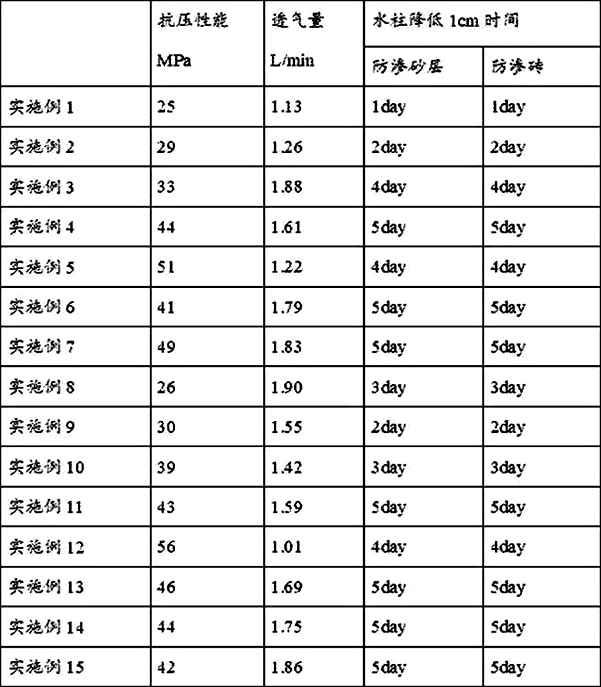

Examples

preparation example Construction

[0031] In the preparation process of coral sand air-permeable and anti-seepage sand of the present invention, it is preferable to mix the coral sand particles with the ethanol solution / ethanol dispersion of the filler and then dry them, and then add the coating agent after ball milling, so as to effectively remove the coral sand surface. Loose and unstable parts can improve the single particle strength of coral sand; more preferably, ball milling pretreatment is performed on coral sand before filling and mixing, which can better improve the sphericity of coral sand and remove coral sand at the same time Parts that are loose and not firm on the surface.

[0032] The coral sand air-permeable and anti-seepage sand described in the present invention can be in the form of loose sand, which is convenient for later pavement to adapt to various places with anti-permeation gas requirements, and can also be directly molded and solidified to form air-permeable and anti-seepage bricks, etc...

Embodiment 1

[0034] The coral sand breathable and anti-seepage sand provided in this embodiment includes 100 g of coral sand particles with a particle size in the range of 50 to 200 mesh, 20 g of cement, 5 g of hydrophobic epoxy resin, and 8 g of silica gel adhesive.

[0035] The preparation method is as follows: screen coral sand particles, collect 100g of coral sand particles in the range of 50-200 meshes, mix with 20g of cement and an appropriate amount of water, add 5g of hydrophobic epoxy resin and corresponding curing agent, stir until the mixture is uniform, Then add 8g of silicone adhesive, mix well and cure.

Embodiment 2

[0037]The coral sand air-permeable and anti-seepage sand provided in this embodiment includes 100g of coral sand particles with a particle size in the range of 50-200 meshes, 20g of styrene-acrylic emulsion, 0.2g of sodium carboxymethyl cellulose, 0.05g of polyvinyl alcohol, hydrophobic 3g of epoxy resin and 8g of silicone adhesive.

[0038] The preparation method is as follows: screen coral sand particles, collect 100g of coral sand particles in the range of 50-200 mesh, mix with 20g of styrene-acrylic emulsion, 0.2g of sodium carboxymethyl cellulose, and 0.05g of polyvinyl alcohol, and add hydrophobic ring Mix 3g of epoxy resin and corresponding curing agent until evenly mixed, then add 8g of silicone adhesive to cure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com