Laboratory model testing device for tunnel excavation

An indoor model and tunnel excavation technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inconvenient operation, ignoring the role of initial support, and soil collapse around the excavated tunnel. The effects of promotion and application, good accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

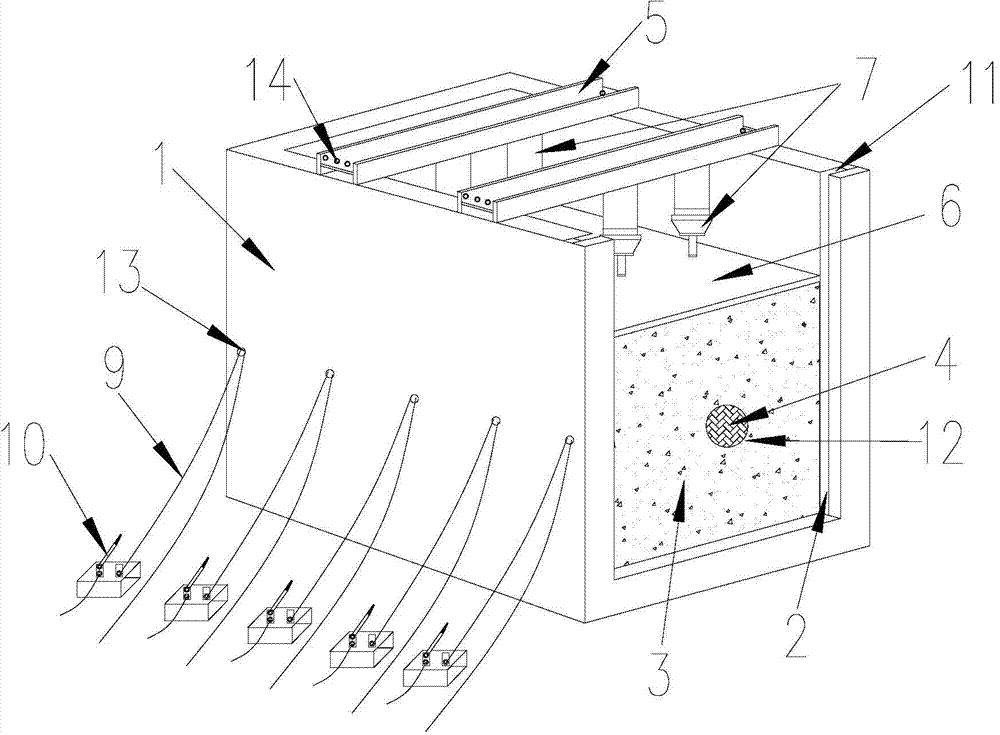

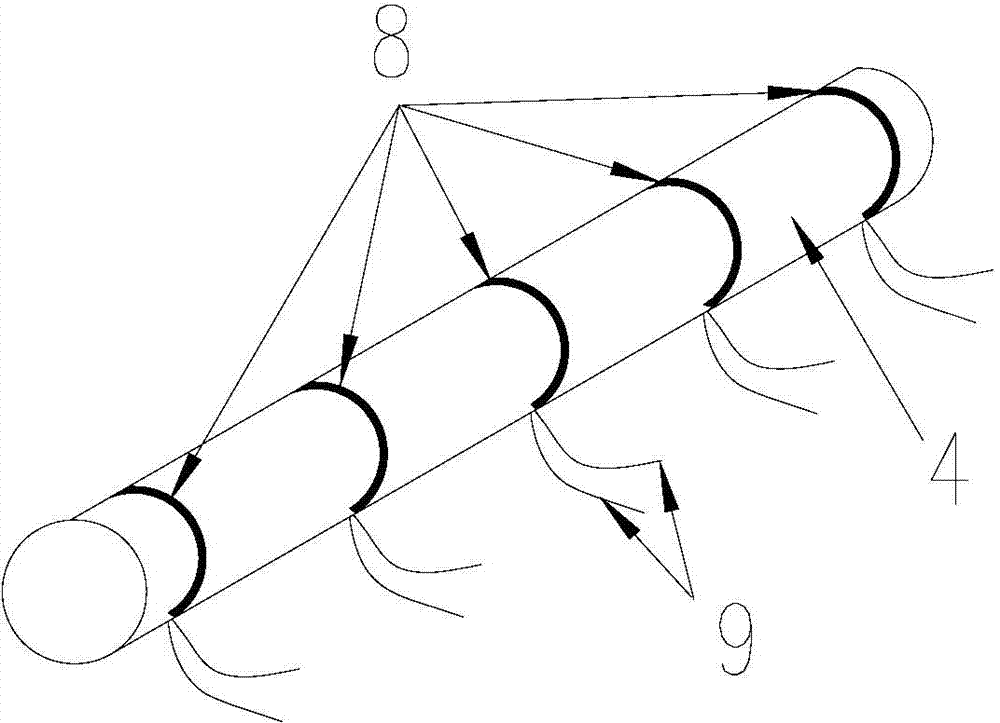

[0024] An indoor model test device for tunnel excavation, including a model box, a tunnel structure model 4, a loading device and an excavation device. The model box is composed of a trench 1 and a plexiglass plate 2, and an opening is arranged on one side of the trench 1. Both ends of the opening are provided with grooves 11, and the plexiglass plate 2 is fixed on one side of the opening of the trough 1 through the groove 11. The thickness of the plexiglass plate 2 is 10-15 mm, and it is colorless and transparent. A hole 12 slightly larger than the section of the tunnel is convenient for observing real-time changes and displacements of fillers around the tunnel structure model.

[0025] The model box is filled with a model test filler 3, the model test filler 3 is mainly composed of soil and stone,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com