Soldering paste of Sn-Bi-Cu self-packed composite powder and preparation method thereof

A composite powder and wrapping technology, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of unsuitable solder joint density and small solder joint volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

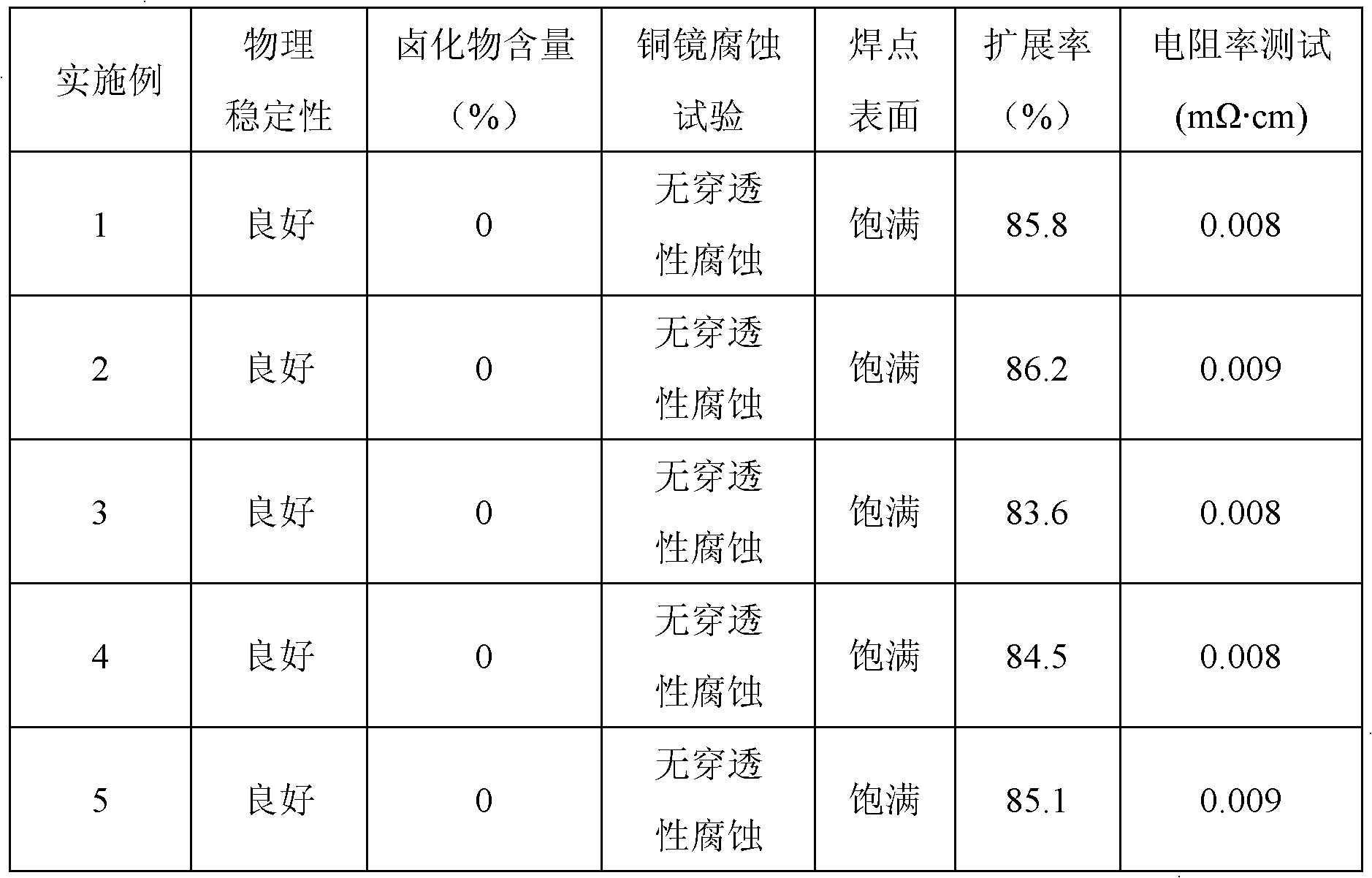

Embodiment 1

[0028] According to the mass percentage, the Sn-Bi-Cu self-wrapped composite powder accounts for 88%, and the soldering flux for soldering paste accounts for 12%.

[0029] In the Sn-Bi-Cu self-wrapping composite powder, the content of each component is 41.5% of Sn, 48.2% of Bi, and the balance is Cu in terms of mass percentage.

[0030] In the flux for soldering paste, by mass percentage, the content of each component is hydrogenated rosin 15%, ordinary rosin 8%, adipic acid 12%, triethanolamine 5%, benzotriazole 1%, OP-100.3 %, hydrogenated castor oil 3%, ethylene glycol monobutyl ether 3%, glycerol 15%, and the balance is absolute ethanol.

[0031] The specific preparation method of described Sn-Bi-Cu self-wrapped composite powder solder paste is given below:

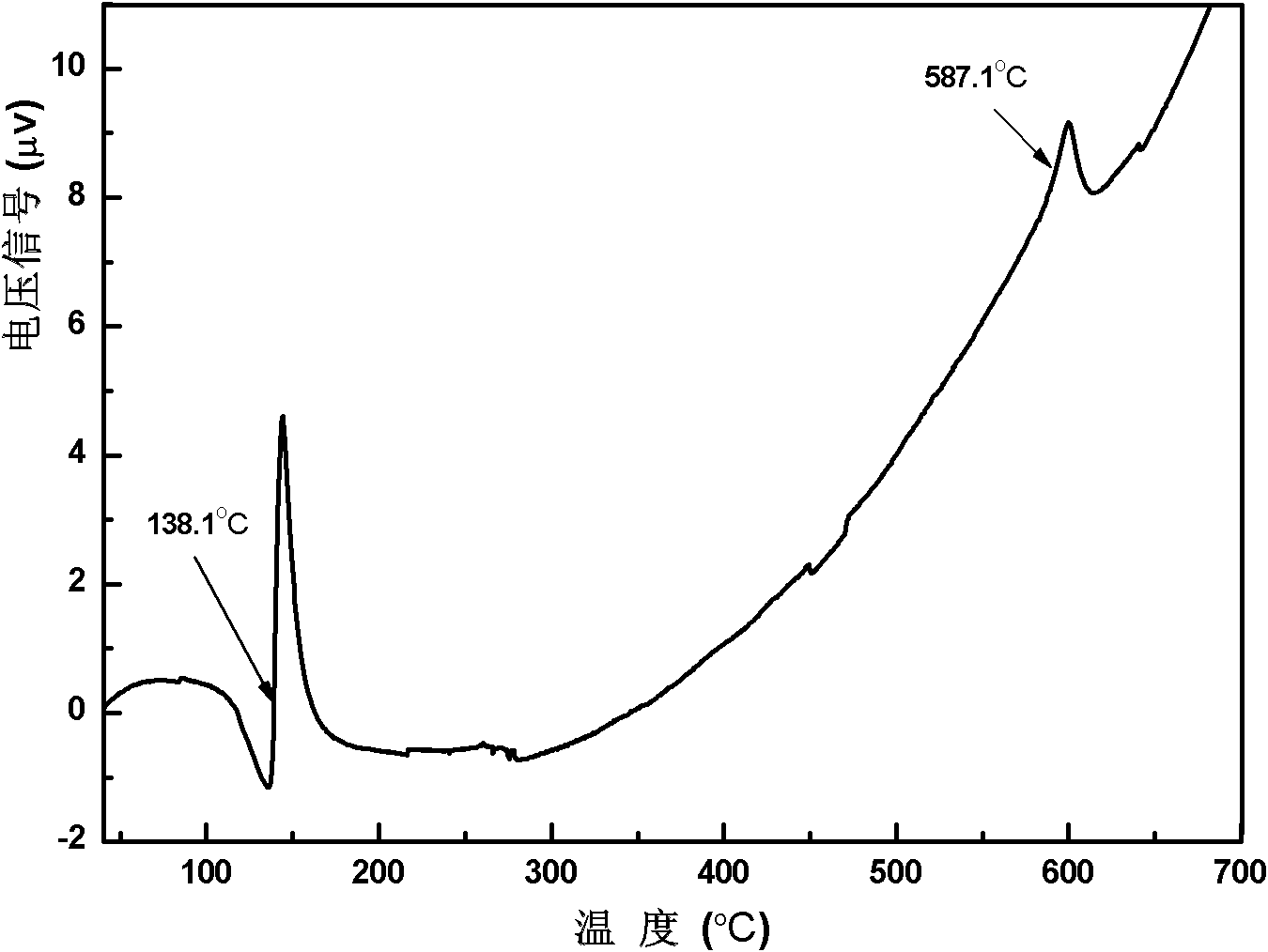

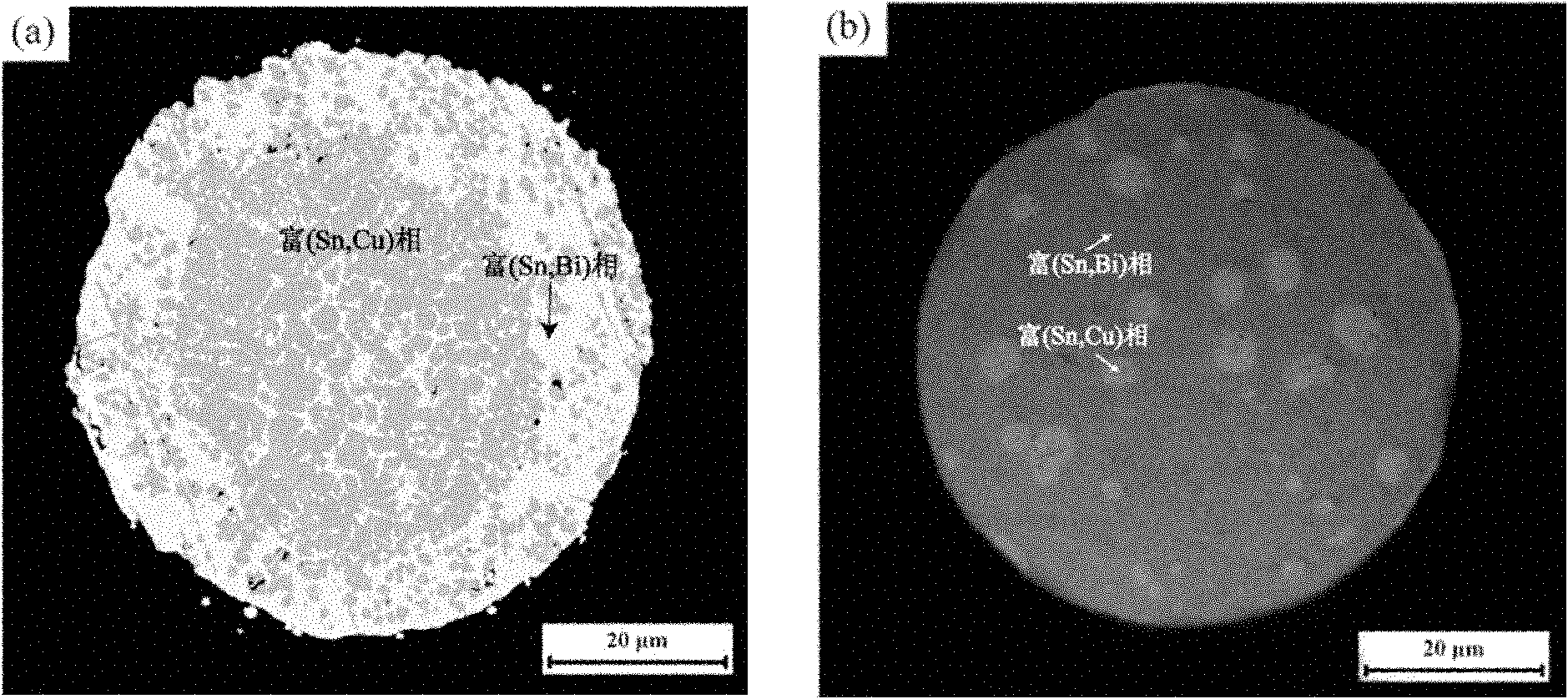

[0032] 1) Prepare self-encapsulated composite powder by atomization method according to the ratio of Sn, Bi and Cu mentioned above.

[0033] 2) Prepare the mixed solution A of absolute ethanol, glycerol and ethylene...

Embodiment 2

[0039] According to the mass percentage, the Sn-Bi-Cu self-wrapped composite powder accounts for 90%, and the soldering flux for soldering paste accounts for 10%.

[0040] In the Sn-Bi-Cu self-wrapped composite powder, the content of each component is 38.2% of Sn, 46.1% of Bi, and the balance is Cu.

[0041] In the soldering flux for soldering paste, by mass percentage, the content of each component is water white rosin 12%, ordinary rosin 13%, adipic acid 10%, oxalic acid 3%, triethanolamine 5%, benzotriazole 0.5% %, triethylamine 0.3%, OP-100.5%, hydrogenated castor oil 5%, ethylene glycol monobutyl ether 2%, triethylene glycol 25%, and the balance is isopropanol.

[0042] Preparation method is with embodiment 1.

Embodiment 3

[0044] According to the mass percentage, the Sn-Bi-Cu self-wrapped composite powder accounts for 89%, and the solder flux for soldering paste accounts for 11%.

[0045] In the Sn-Bi-Cu self-wrapped composite powder, according to mass percentage, the content of each component is 42.6% of Sn, 47.3% of Bi, and the balance is Cu.

[0046]In the soldering flux for soldering paste, by mass percentage, the content of each component is hydrogenated rosin 8%, water white rosin 15%, adipic acid 8%, citric acid 8%, triethanolamine 3%, triethylamine 0.6% , vitamin C 0.3%, OP-100.3%, hydrogenated castor oil 4%, ethylene glycol monobutyl ether 6%, triethylene glycol 30%, and the balance is absolute ethanol.

[0047] Preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com