Preparation method for extra hydrophobic carbon fabric boat

A carbon fiber fabric and super-hydrophobic technology, applied in carbon fiber, fiber treatment, ship parts, etc., can solve the problems of low surface energy and poor bonding performance, and achieve the effect of small driving resistance, light weight and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

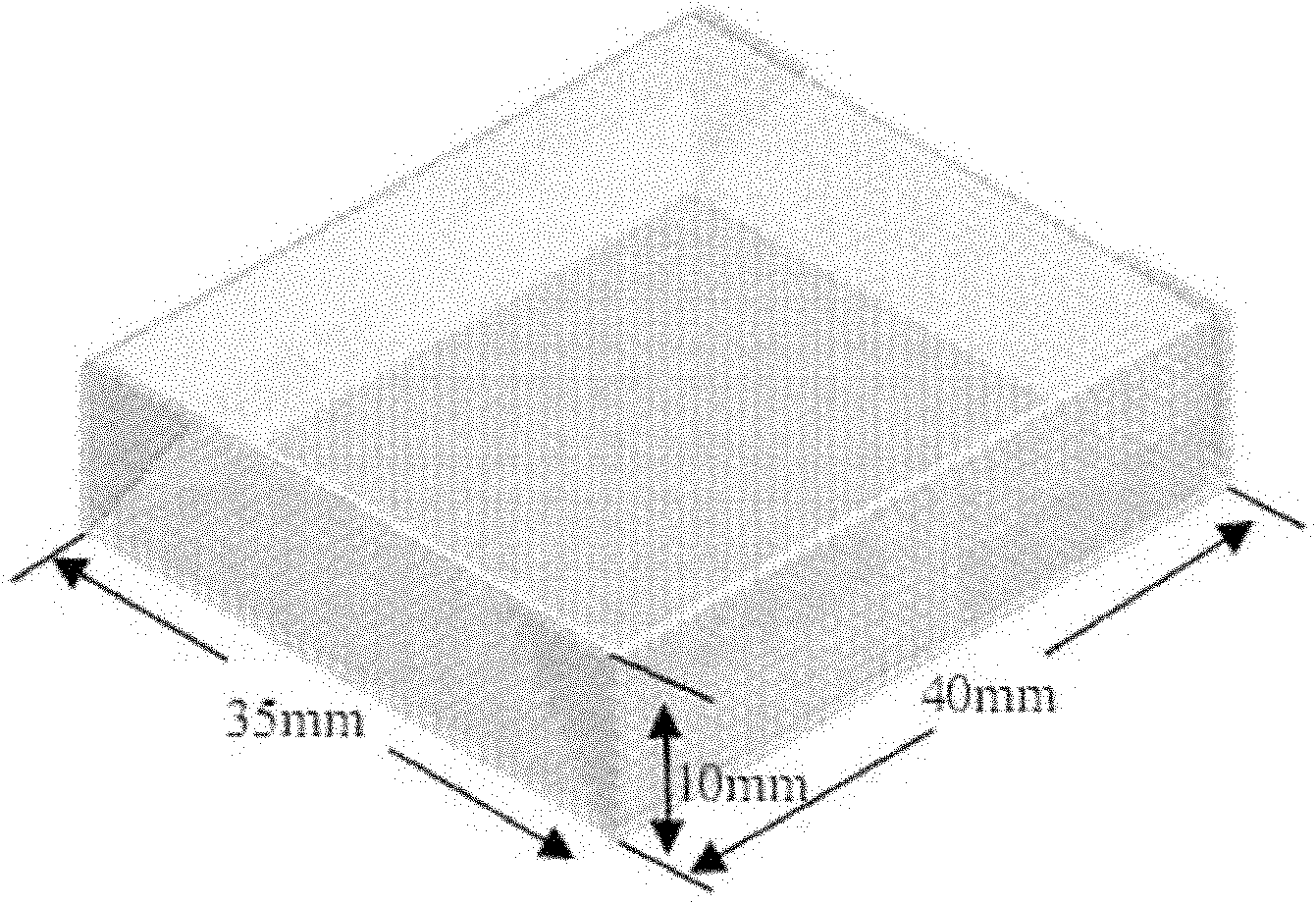

specific Embodiment approach 1

[0010] Specific embodiment one: the preparation method of the superhydrophobic carbon fiber fabric boat in the present embodiment is as follows: one, by weight percentage by 0.1%~8% perfluoroalkyl siloxane, 1%~10% water, 1%~10% Acid, the rest is ethanol mixed solution composed of ultrasonic treatment for 30min ~ 120min, forming a perfluoroalkyl siloxane solution; 2. Immerse the carbon fiber fabric in the perfluoroalkyl siloxane solution for 10s ~ 60s, and then dry it; 3. Repeat step 2 for 2 to 5 times; 4. Dry the carbon fiber fabric treated in step 3 at 80°C to 150°C for 3h to 12h; 5. Wrap the carbon fiber fabric treated in step 4 outside the boat-shaped support to obtain super Hydrophobic carbon fiber fabric boat.

specific Embodiment approach 2

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the general chemical formula of perfluoroalkylsiloxane described in step 1 is CF 3 (CF 2 ) n Si(OC m h 2m+1 ) 3 , where n ranges from 2 to 200, and m ranges from 1 to 200. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the perfluoroalkylsiloxane chemical formula CF described in step one 3 (CF 2 ) n Si(OC m h 2m+1 ) 3 The value range of n is 3-18, and the value range of m is 1.5-2.5. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com