Super-hydrophobic sponge ball as well as preparation method and application thereof

A technology of super-hydrophobic sponge and sponge ball, which is applied in the field of super-hydrophobic sponge and its preparation, which can solve the problems of inability to efficiently collect and separate oil and organic pollutants, high absorption capacity of sponge, and lack of hydrophobic effect, etc., to achieve excellent mechanical Effect of stability, high absorbency, best chemical stability and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

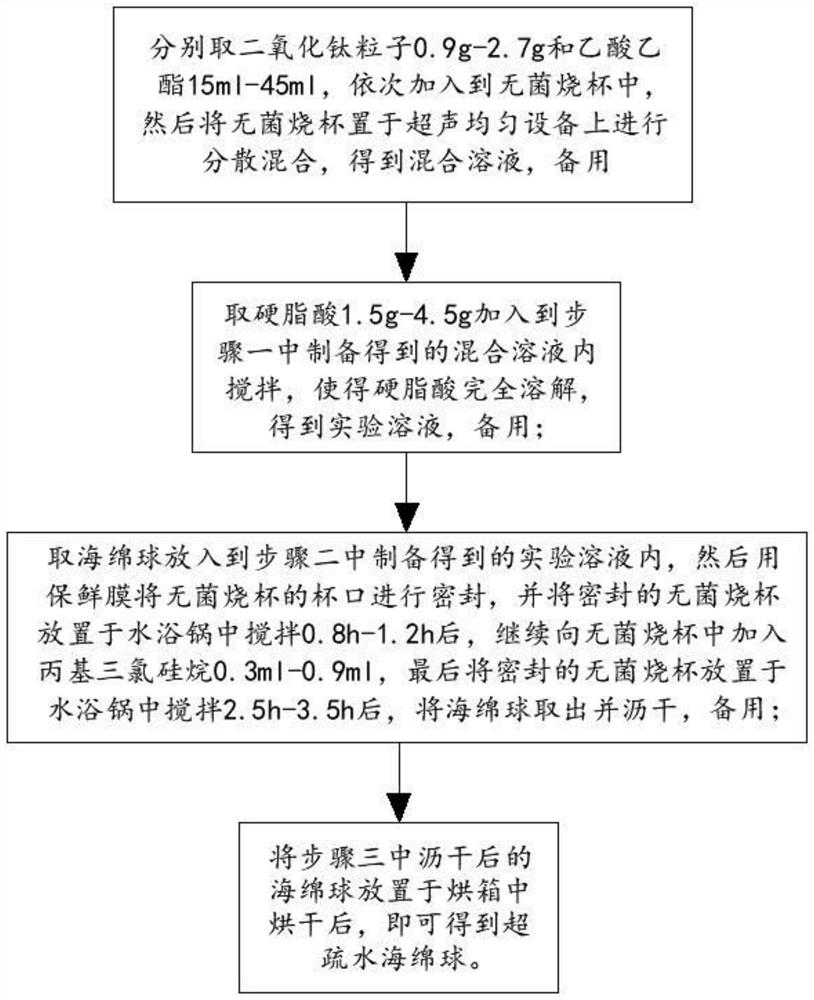

[0035] This embodiment provides a method for preparing a superhydrophobic sponge ball, comprising the following steps;

[0036] Step 1: Take 1.8g of titanium dioxide particles and 30ml of ethyl acetate, respectively, and add them to the beaker in turn, and then place the beaker on an ultrasonic uniform device for dispersion and mixing to obtain a mixed solution for later use;

[0037] Step 2: Take 3 g of stearic acid and add it into the mixed solution prepared in step 1 and stir, so that the stearic acid is completely dissolved to obtain the experimental solution, which is set aside;

[0038] Step 3: Put the sponge ball into the experimental solution prepared in step 2, then seal the mouth of the beaker with plastic wrap, place the sealed beaker in a water bath and stir for 1 hour, then continue to add Propyltrichlorosilane 0.6ml, and finally place the sealed beaker in a water bath and stir for 3 hours, then take out the sponge ball and drain it for later use;

[0039] Step 4...

Embodiment 2

[0049] This embodiment provides a method for preparing a superhydrophobic sponge ball, comprising the following steps;

[0050] Step 1: Take 0.9g of titanium dioxide particles and 15ml of ethyl acetate, respectively, and add them to the beaker in turn, and then place the beaker on an ultrasonic uniform device for dispersion and mixing to obtain a mixed solution for later use;

[0051] Step 2: Add 1.5 g of stearic acid into the mixed solution prepared in step 1 and stir to completely dissolve the stearic acid to obtain the experimental solution for later use;

[0052] Step 3: Put the sponge ball into the experimental solution prepared in step 2, then seal the mouth of the beaker with plastic wrap, place the sealed beaker in a water bath and stir for 0.8h, then continue pouring into the beaker Add 0.3ml of propyltrichlorosilane, and finally place the sealed beaker in a water bath and stir for 2.5 hours, then take out the sponge ball and drain it for later use;

[0053] Step 4: ...

Embodiment 3

[0061] This embodiment provides a method for preparing a superhydrophobic sponge ball, comprising the following steps;

[0062] Step 1: Take 2.7g of titanium dioxide particles and 45ml of ethyl acetate, respectively, and add them to the beaker in turn, and then place the beaker on an ultrasonic uniform device for dispersion and mixing to obtain a mixed solution for later use;

[0063] Step 2: Add 4.5 g of stearic acid into the mixed solution prepared in step 1 and stir, so that the stearic acid is completely dissolved to obtain the experimental solution and set aside;

[0064] Step 3: Put the sponge ball into the experimental solution prepared in step 2, then seal the mouth of the beaker with a plastic wrap, place the sealed beaker in a water bath and stir for 1.2 hours, then continue pouring into the beaker Add 0.9ml of propyltrichlorosilane, and finally place the sealed beaker in a water bath and stir for 3.5 hours, then take out the sponge ball and drain it for later use; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com