Fuel cell membrane electrode gas diffusion layer and its microporous layer preparation method and application

A gas diffusion layer, fuel cell membrane technology, applied in fuel cells, electrical components, coatings, etc., can solve the problems of complex experimental process, excessive dependence on fluoropolymers, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

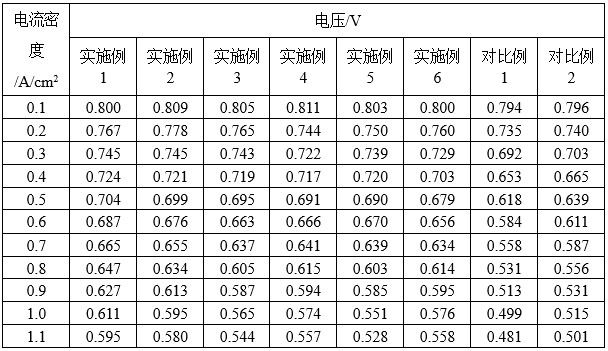

Examples

preparation example Construction

[0026] The invention provides a method for preparing a microporous layer of a gas diffusion layer of a fuel cell membrane electrode, comprising the following steps:

[0027] Dissolving organosiloxane, active monomer, photoinitiator, coupling agent and carbon material in an organic solvent according to a predetermined ratio, stirring and dispersing to form a uniformly mixed slurry;

[0028] Coating the slurry on one side of the hydrophobically treated support layer until the loading of carbon material is 0.5-3.0 mg / cm 2 , to obtain a support layer with slurry;

[0029] The support layer with the slurry is placed in an ultraviolet curing box for curing, and a microporous layer is formed on the support layer.

[0030] In a further embodiment, the slurry includes the following components: organosiloxane 10wt%-40wt%, active monomer 1wt%-2wt%, photoinitiator 0.1wt%-1wt%, coupling agent 0.5wt% -2.5wt%, carbon material 5wt%-20wt%, and the rest is solvent.

[0031] Among them, the o...

Embodiment 1

[0043] 1. Mix polydimethylsiloxane (organosiloxane, concentration 10wt%) 1g, 1, 6-hexanediol diacrylate (active monomer) 0.1g, diphenyltrimethylbenzoyl Phosphine oxide (photoinitiator) 0.01g, γ-methacryloxypropyltrimethoxysilane (coupling agent) 0.05g, carbon black (carbon material) 0.5g dissolved in 8.3g xylene (organic solvent) , stirring and dispersing to form a uniformly mixed slurry.

[0044] 2. Coat the slurry in step 1 on one side of the hydrophobically treated support layer by scraping, spraying or screen printing until the loading of carbon material is 1.0 mg / cm 2 .

[0045] 3. Place the sample in a UV curing box for curing, curing conditions: room temperature, UV wavelength 365nm, curing energy 1600mJ / cm 2 , the curing time is 1min, and the microporous layer of the gas diffusion layer is obtained.

Embodiment 2

[0047] 1. Mix polydimethylsiloxane (organosiloxane, concentration 10wt%) 1g, 1, 6-hexanediol diacrylate (active monomer) 0.1g, diphenyltrimethylbenzoyl Phosphine oxide (photoinitiator) 0.01g, γ-methacryloxypropyltrimethoxysilane (coupling agent) 0.05g, carbon black (carbon material) 1g dissolved in 7.8g xylene (organic solvent) , stirring and dispersing to form a uniformly mixed slurry.

[0048] 2. Coat the slurry in step 1 on one side of the hydrophobically treated support layer by scraping, spraying or screen printing until the loading of carbon material is 1.0 mg / cm 2 .

[0049] 3. Place the sample in a UV curing box for curing, curing conditions: room temperature, UV wavelength 365nm, curing energy 1600mJ / cm 2 , the curing time is 1min, and the microporous layer of the gas diffusion layer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com