Preparation method of hydrophobic textile with porous surface structure

A hydrophobic and hydrophobic technology, applied in textiles and papermaking, liquid-repellent fibers, animal fibers, etc., can solve the problems of fabric performance degradation, high finishing temperature, self-cleaning performance is difficult to meet the requirements, etc., to achieve super-hydrophobic performance Excellent, effect of improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A kind of method for preparing hydrophobic cotton fabric

[0029] Get 0.090g fluorine-containing POSS block copolymer POSS-(PTFEMA) 8 (molecular weight 13500) dissolved in 1 mL of chloroform (CHCl 3 ), prepared as a solution. Wet the cotton fabric completely in the solution, take it out after 10 minutes and immediately place it in an atmosphere with a humidity of 90%, and obtain a cotton fabric with a porous structure after the solvent and water on the surface of the cotton fabric are completely volatilized. Its contact angle with water is 154.0°.

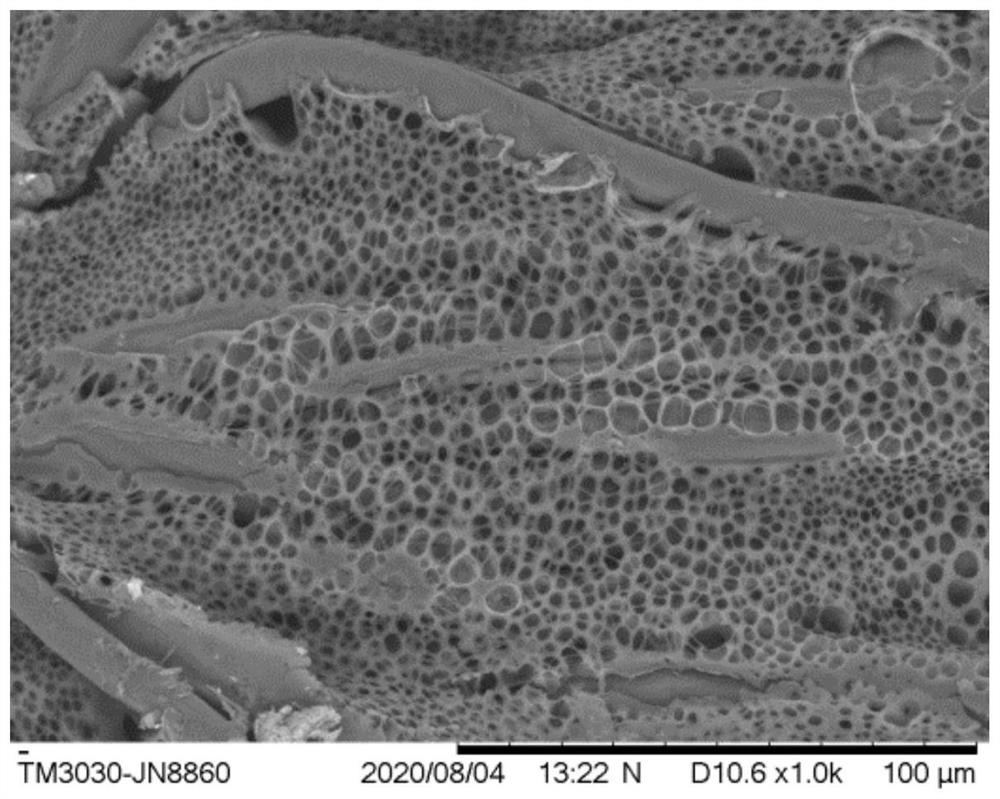

[0030] see figure 1 , a cotton fabric with a porous structure prepared in this example. This is because the selected solvent of the present invention is easy to volatilize and is immiscible with water. During the film-forming process, the solvent volatilizes quickly to produce a certain temperature gradient, and the sharp drop in the surface temperature of the polymer solution causes the water vapor in the ...

Embodiment 2

[0031] Embodiment 2: a kind of method for preparing hydrophobic cotton fabric

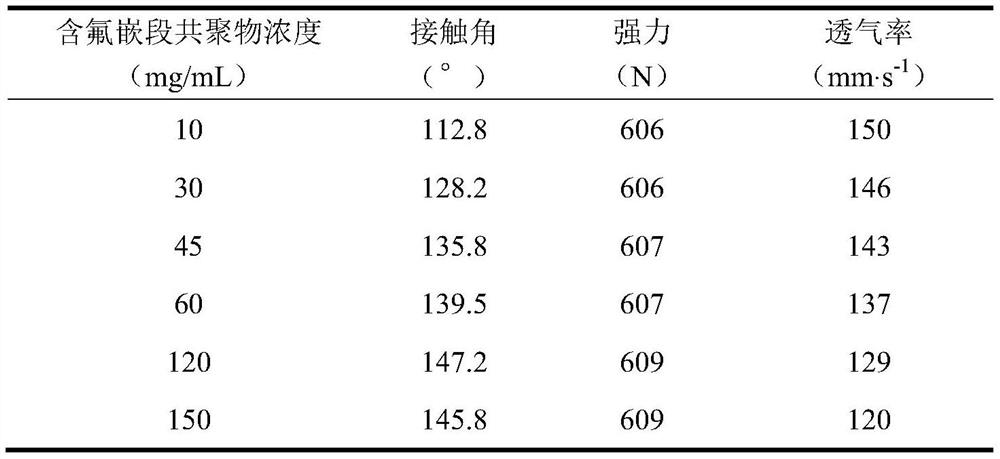

[0032] Prepare hydrophobic cotton fabric with reference to the method of Example 1, the only difference is that the addition amount of the fluorine-containing block copolymer in Example 1 is adjusted, respectively 0.010g, 0.030g, 0.045g, 0.060g, 0.120g, 0.150 g, so that the concentrations of the fluorine-containing block copolymers are 10 mg / mL, 30 mg / mL, 45 mg / mL, 60 mg / mL, 120 mg / mL, and 150 mg / mL, respectively. Other conditions or parameters are consistent with Example 1. The contact angle, strength and air permeability of the prepared cotton fabric are shown in Table 1. This shows that the concentration of the fluorine-containing POSS block copolymer has a great effect on the improvement of the surface hydrophobicity of the cotton fabric, the strength remains basically unchanged and slightly increases, and the air permeability decreases with the increase of the concentration.

[0033] Table 1...

Embodiment 3

[0035] Embodiment 3: a kind of method for preparing hydrophobic cotton fabric

[0036] Prepare hydrophobic cotton fabric with reference to the method of Example 1, the only difference is that the humidity in Example 1 is changed to 50%, 70%, and 100%, and other conditions or parameters are consistent with Example 1. Neither 50% nor 100% humidity can form a regular porous structure. When the humidity is 70%, the contact angle of the cellulose film is 142.6°, the strength is 607N, and the air permeability is 128mm s -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com