A modified composite fiber membrane for oil-water separation and its preparation method

A technology of oil-water separation and nanofiber membrane, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of poor selectivity, low membrane flux, and low removal rate of oil-water separation membranes, and achieve excellent physical and chemical properties , good film-forming performance, and the effect of increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

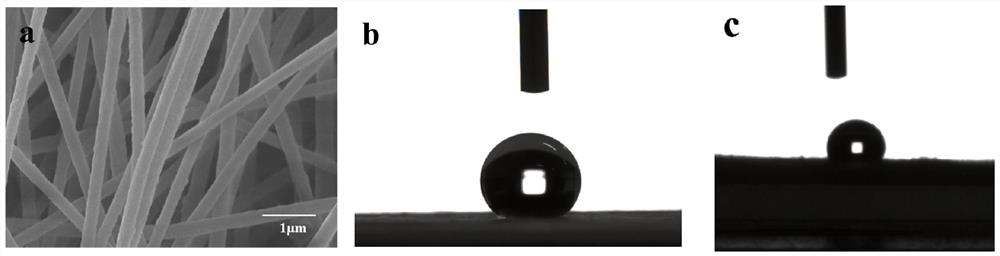

Embodiment 1

[0049] ① Preparation of MOFs

[0050] MOFs are prepared by adding 0.0172mol / L zirconium tetrachloride (ZrCl 4 ), 0.0172mol / L 2-aminoterephthalic acid was dissolved in a mixed solvent with a ratio of 3 / 100 (V / V) acetic acid and N,N-dimethylformamide, and the reaction was stirred at 100°C for 24h, The resulting particles were centrifuged and washed three times with N,N-dimethylformamide to obtain the MOFs.

[0051] ② Preparation of PAN solution

[0052] The PAN solution is prepared by uniformly mixing polyacrylonitrile with a molecular weight of 150,000 and solvent N,N-dimethylformamide at 60° C. according to the weight percentage of 20 wt % and 80 wt %.

[0053] ③ Preparation of MOFs solution

[0054] The MOFs solution is prepared by uniformly mixing the MOFs obtained in step ① and the solvent N,N-dimethylformamide at 0.4wt% and 99.6wt% at room temperature.

[0055] ④ Preparation of casting solution

[0056] The casting solution is prepared by mixing the solutions obtained...

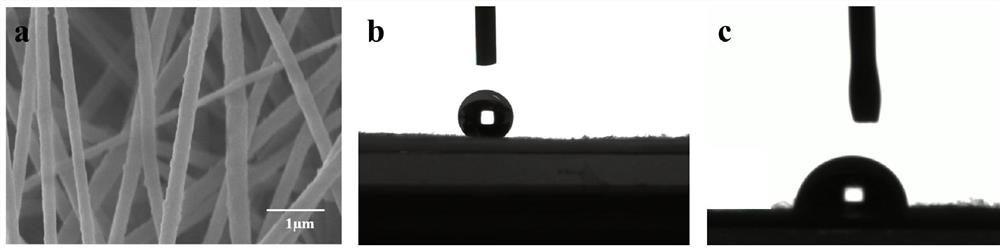

Embodiment 2

[0063] ① Preparation of MOFs

[0064] MOFs are prepared by adding 0.0172mol / L zirconium tetrachloride (ZrCl 4 ), 0.0172mol / L 2-aminoterephthalic acid was dissolved in a mixed solvent with a ratio of 3 / 100 (V / V) acetic acid and N,N-dimethylformamide, and the reaction was stirred at 100°C for 24h, The resulting particles were centrifuged and washed three times with N,N-dimethylformamide to obtain the MOFs.

[0065] ② Preparation of PAN solution

[0066] The PAN solution is prepared by uniformly mixing polyacrylonitrile with a molecular weight of 150,000 and solvent N,N-dimethylformamide at 60° C. according to the weight percentage of 20 wt % and 80 wt %.

[0067] ③ Preparation of MOFs solution

[0068] The MOFs solution is prepared by uniformly mixing the MOFs obtained in step ① and the solvent N,N-dimethylformamide at 1 wt% and 99 wt% at room temperature.

[0069] ④ Preparation of casting solution

[0070] The casting solution is prepared by mixing the solutions obtained i...

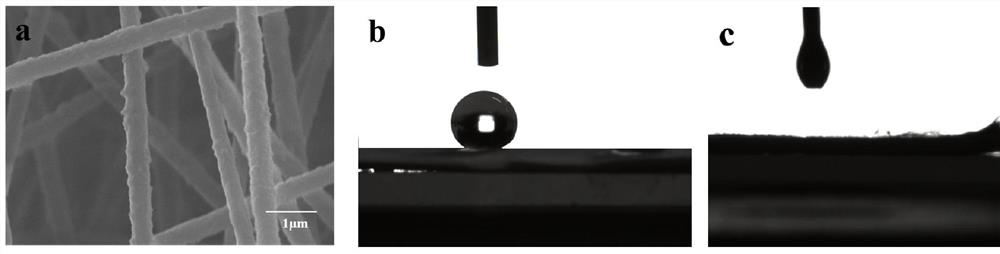

Embodiment 3

[0077] ① Preparation of MOFs

[0078] MOFs are prepared by adding 0.0172mol / L zirconium tetrachloride (ZrCl 4 ), 0.0172mol / L 2-aminoterephthalic acid was dissolved in a mixed solvent with a ratio of 3 / 100 (V / V) acetic acid and N,N-dimethylformamide, and the reaction was stirred at 100°C for 24h, The resulting particles were centrifuged and washed three times with N,N-dimethylformamide to obtain the MOFs.

[0079] ② Preparation of PAN solution

[0080] The PAN solution is prepared by uniformly mixing polyacrylonitrile with a molecular weight of 150,000 and solvent N,N-dimethylformamide at 60° C. according to the weight percentage of 20 wt % and 80 wt %.

[0081] ③ Preparation of MOFs solution

[0082] The MOFs solution is prepared by uniformly mixing the MOFs obtained in step ① and the solvent N,N-dimethylformamide at 2wt% and 98wt% by weight at room temperature.

[0083] ④ Preparation of casting solution

[0084] The casting solution is prepared by mixing the solutions ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com