A kind of carbon fluoride film and its preparation method and use

A technology of carbon fluoride and carbon fluoride, which is applied in the direction of gaseous chemical plating, semiconductor/solid-state device manufacturing, coating, etc., can solve the problems of slow preparation speed, long cycle, poor physical and chemical properties of the film, and achieve the preparation cycle Short, easy-to-operate, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

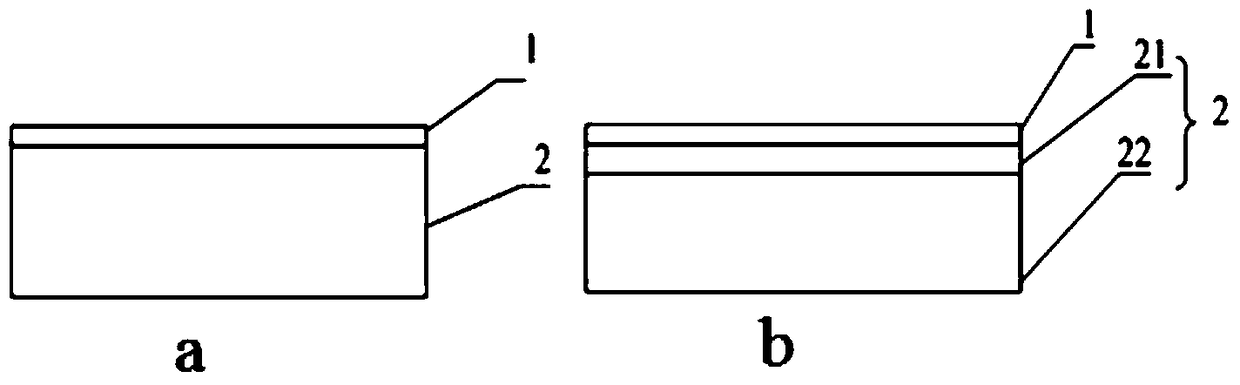

[0050] Prepare a carbon fluoride film on the surface of n-Si, the preparation method is as follows:

[0051] (1) Apply thermal oil on the back of n-Si to make the substrate fully contact with the tray;

[0052] (2) Send the substrate into the ICP high-density plasma etching system with a background vacuum of 10 -5 Pa, into the working gas CHF 3 , CHF 3 The flow rate is 60sccm, the processing temperature is 0°C, the working pressure is 0.4Pa, the ICP power of the upper electrode is 200W, the RF power of the lower electrode is 10W, and the processing time is 160s;

[0053] (3) The treated substrate was ultrasonically cleaned in isopropanol for 5 min, and cleaned with N 2 Blow dry to obtain a 50nm thick carbon fluoride film on the n-Si surface.

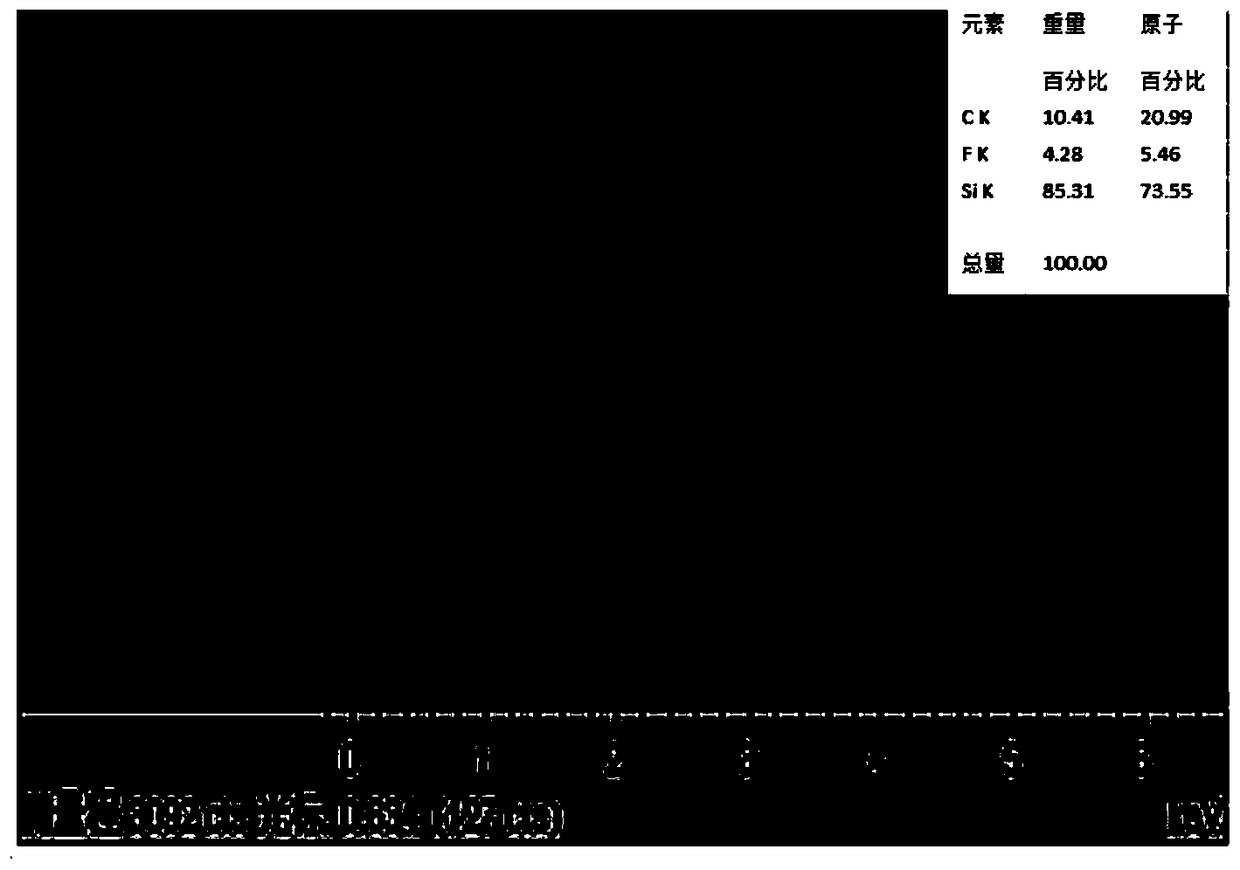

[0054] Energy spectrum analysis was carried out on the treated substrate surface, and the results were as follows: figure 2 shown, from figure 2 It can be seen that the number ratio of fluorine and carbon atoms in the material ob...

Embodiment 2

[0057] Prepare carbon fluoride film on the surface of the glass (Glass / AR) coated with anti-reflection film, the preparation method is the same as embodiment 1, the difference is:

[0058] The substrate described in step (1) is glass (Glass / AR) coated with an anti-reflection film, and the material of the outermost layer of the anti-reflection film is MgF 2 ;

[0059] In step (2), the working air pressure is 0.8Pa, and the processing time is 250s.

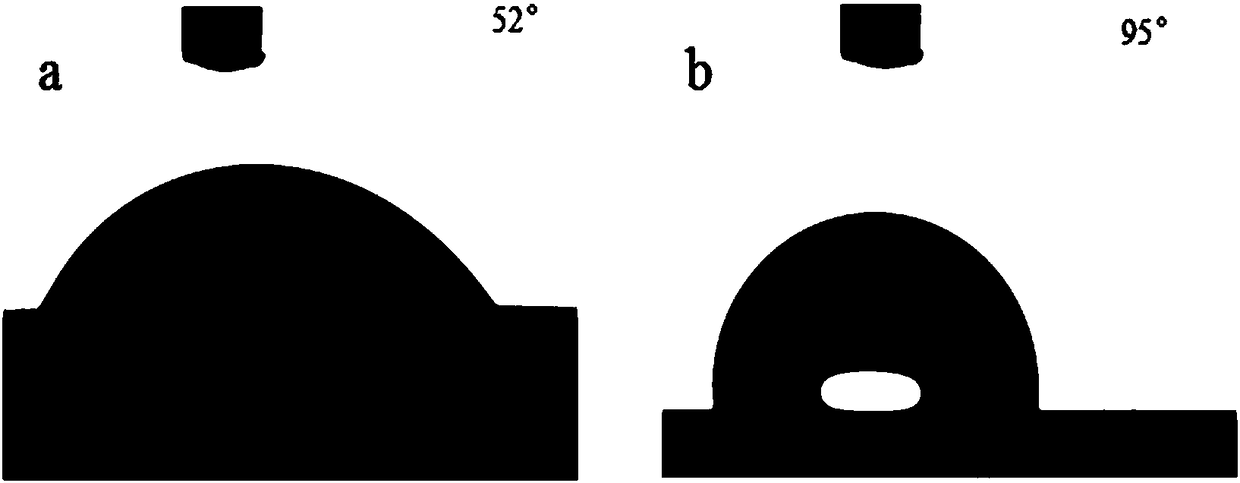

[0060] Figure 4 is the comparison of water contact angles before and after F-based treatment on the Glass / AR surface, determined by Figure 4 It can be seen that the F-based treatment can change the contact angle of the Glass / AR surface from 44° (such as Figure 4 a) Increased to 108° (such as Figure 4 b), it can be seen that the contact angle of the Glass / AR surface treated with F group is greater than 90°, achieving a hydrophobic effect.

Embodiment 3

[0062] Prepare carbon fluoride film on the glass (Glass / HR) surface that is coated with metal high reflection film, preparation method is the same as embodiment 1, and difference is:

[0063] The substrate used in the step (1) is glass (Glass / HR) coated with a highly reflective metal film, and the metal film is an aluminum film;

[0064] In step (2), the working air pressure is 0.8Pa, and the processing time is 250s.

[0065] Figure 5 It is a comparison diagram of the water contact angle after F-based treatment on the surface of Glass / HR. It can be seen from the figure that the F-based treatment can increase the water contact angle of the Glass / HR surface to 110.4°, which is greater than 90°, achieving a hydrophobic effect .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com