Polyimide precursor, polyimide, polyimide film and preparation method and application thereof

A technology of polyimide precursor and polyimide film, which is applied in the field of polyimide, can solve the problems of polyimide material performance difference, film thermal performance and mechanical performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

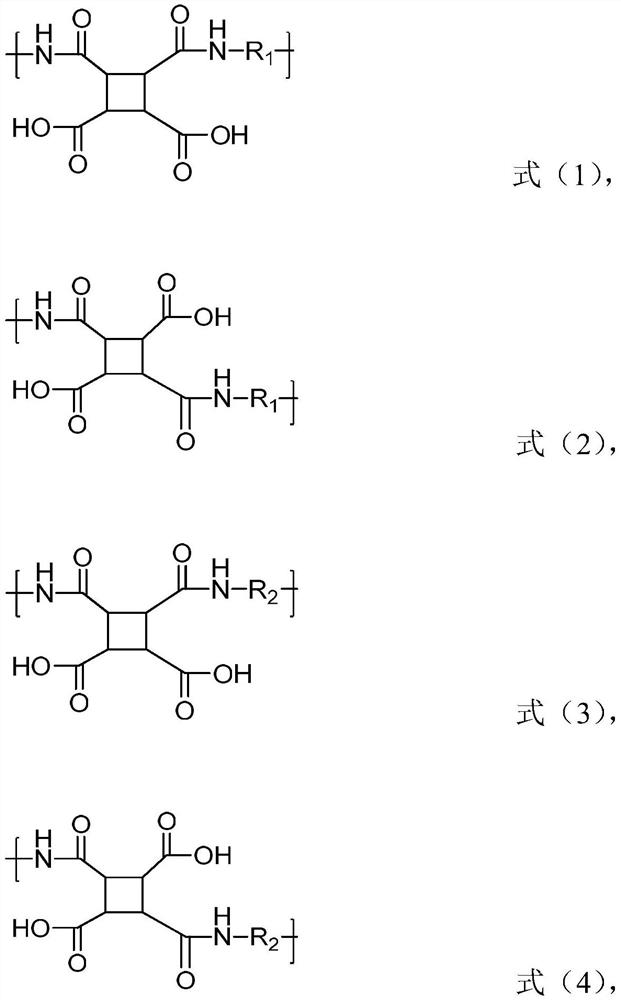

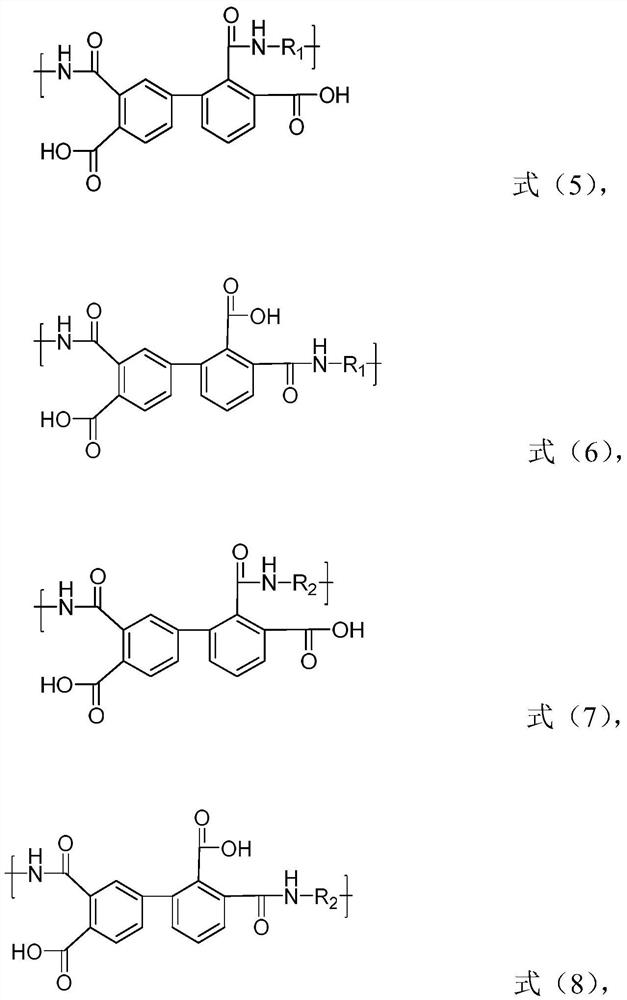

Method used

Image

Examples

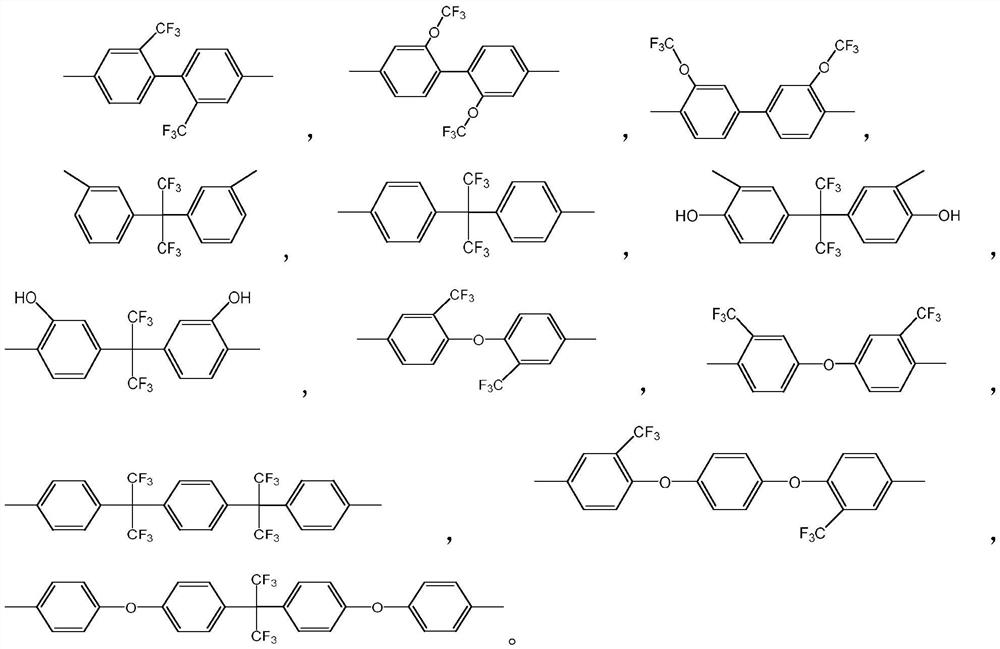

Embodiment 1

[0069] 1. Stock solution preparation: 2.56kg 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl and 0.67kg 2,2-bis(4-aminophenyl)hexafluoropropane at 25°C Stir and dissolve in 31.05kg N,N-dimethylacetamide (DMAc), after complete dissolution, add 0.88kg 2,3,3',4'-biphenyltetracarboxylic dianhydride and 1.37kg 1,2,3 , 4-cyclobutanetetracarboxylic dianhydride (CBDA), fully stirred for 24 hours to obtain a polyimide precursor. The polyimide precursor is filtered through 5 μm and 0.5 μm filter membranes in sequence, and then degassed under reduced pressure to obtain a polyimide film-forming stock solution.

[0070] 2. Cast film formation: The film-forming stock solution is extruded through the film head, and the wet film thickness is controlled to 500 μm, and cast on a smooth steel belt to form a film.

[0071] 3. Pre-baking treatment: The film-forming stock solution is passed through a heating furnace at 85°C under a nitrogen flowing atmosphere to remove most of the solvent to obtain a...

Embodiment 2

[0075] 1. Stock solution preparation: Dissolve 3.20kg of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl in 30.37kg of N-methylpyrrolidone (NMP) with stirring at 25°C. , add 0.59kg 2,3,3',4'-biphenyltetracarboxylic dianhydride and 1.57kg 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA), stir well for 24 hours to obtain polyamide Imine precursors. The polyimide precursor is filtered through 5 μm and 0.5 μm filter membranes in sequence, and then degassed under reduced pressure to obtain a polyimide film-forming stock solution.

[0076] 2. Cast film formation: The film-forming stock solution is extruded through the film head, and the wet film thickness is controlled to 500 μm, and cast on a smooth steel belt to form a film.

[0077] 3. Pre-baking treatment: The film-forming stock solution is passed through a heating furnace at 85°C under a nitrogen flowing atmosphere to remove most of the solvent to obtain a self-supporting polyamic acid film.

[0078] 4. Thermal imidization:...

Embodiment 3

[0081] 1. Stock solution preparation: Dissolve 3.52kg of 4,4'-diamino-2,2'-bis(trifluoromethoxy)-p-diaminobenzidine in 33.15kg of N,N-dimethyl In acetamide (DMAC), after completely dissolving, add 1.15kg 2,3,3',4'-biphenyltetracarboxylic dianhydride and 1.18kg 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA ), fully stirred to obtain the polyimide precursor after 24 hours. The polyimide precursor is filtered through 5 μm and 0.5 μm filter membranes in sequence, and then degassed under reduced pressure to obtain a polyimide film-forming stock solution.

[0082] 2. Cast film formation: The film-forming stock solution is extruded through the film head, and the wet film thickness is controlled to 500 μm, and cast on a smooth steel belt to form a film.

[0083] 3. Pre-baking treatment: The film-forming stock solution is passed through a heating furnace at 85°C under a nitrogen flowing atmosphere to remove most of the solvent to obtain a self-supporting polyamic acid film.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com