Anti-icing fluorocarbon emulsion and preparation method thereof

A fluorocarbon emulsion and anti-icing technology, applied in the direction of coating, etc., can solve the problems of high environmental hazards, complex process, high cost, etc., and achieve the effect of simple synthesis process and excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 2 parts of titanium dioxide with an average particle size of 200 nanometers and 3 parts of sodium dodecylbenzenesulfonate to 50 parts of deionized water, and fully emulsify at a stirring speed of 10,000 rpm; In a glass reactor, heat to 95°C at a stirring speed of 500rpm; dissolve 30 parts of hexafluorobutyl methacrylate and 5 parts of methyl methacrylate in 10 parts of ethanol co-solvent to mix the monomer solution, and pour into the reactor Add slowly and dropwise for 2 hours at a constant speed; stop heating after monomer polymerization is complete, and obtain 100 parts of anti-icing fluorocarbon emulsion.

[0028] The above-mentioned fluorocarbon emulsion is directly dip-coated on the surface of a clean polyvinyl chloride resin board, and dried at 100°C for 1 hour to obtain an anti-icing coating.

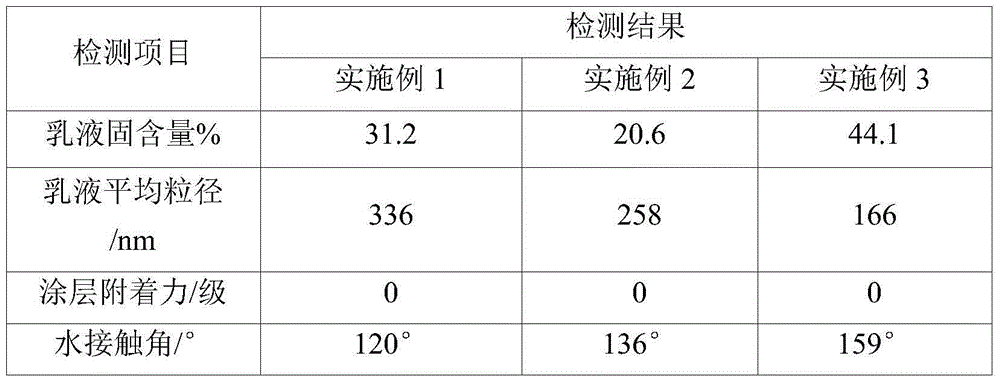

[0029] Test the fluorocarbon emulsion and coating, test the solid content of the emulsion according to the standard GB1725-2007, use the laser light scattering particl...

Embodiment 2

[0031] Add 1 part of carbon black with an average particle size of 70 nanometers, 0.5 part of dibenzoyl peroxide, and 2 parts of nonylphenol polyoxyethylene ether into 76.5 parts of deionized water, and fully emulsify it by ultrasonic treatment; Add the emulsion into a high-pressure stainless steel reactor with a heating and stirring device, and heat it to 60°C at a stirring speed of 200 rpm after nitrogen replacement; slowly feed 20 parts of vinylidene fluoride monomer into the reactor to maintain a reaction pressure of 0.5 MPa ; Stop heating after the pressure drops to normal pressure to obtain 100 parts of anti-icing fluorocarbon emulsion.

[0032] The above-mentioned fluorocarbon emulsion is directly sprayed on the surface of a clean aluminum plate, and vacuum-dried at 250°C for 10 minutes to obtain an anti-icing coating.

[0033] The fluorocarbon emulsion and coating were tested, and the testing items and methods were the same as in Example 1, and the results are shown in...

Embodiment 3

[0035] Add 0.5 parts of fumed silica with an average particle size of 20 nanometers, 2 parts of azobisisobutyronitrile, 0.5 parts of sodium dodecylbenzenebenzenesulfonate, and 0.5 parts of nonylphenol polyoxyethylene ether to 48.5 parts Fully emulsify in deionized water at a stirring speed of 15000rpm; add the emulsion into a high-pressure stainless steel reactor with a heating and stirring device, and heat it to 40°C at a stirring speed of 50rpm; slowly introduce 40 parts of chlorine trifluorochloride into the reactor Ethylene monomer, at the same time, slowly dropwise add a monomer solution mixed with 3 parts of hydroxypropyl vinyl ether and 5 parts of methanol co-solvent to keep the reaction pressure at 0.5 MPa; stop heating after the pressure drops to normal pressure, and obtain anti-icing fluorocarbon 100 parts of emulsion.

[0036] Brush the above-mentioned fluorocarbon emulsion directly on the surface of a clean stainless steel plate, and dry it at room temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com