Stretchable super-hydrophobic surface material and preparation method thereof

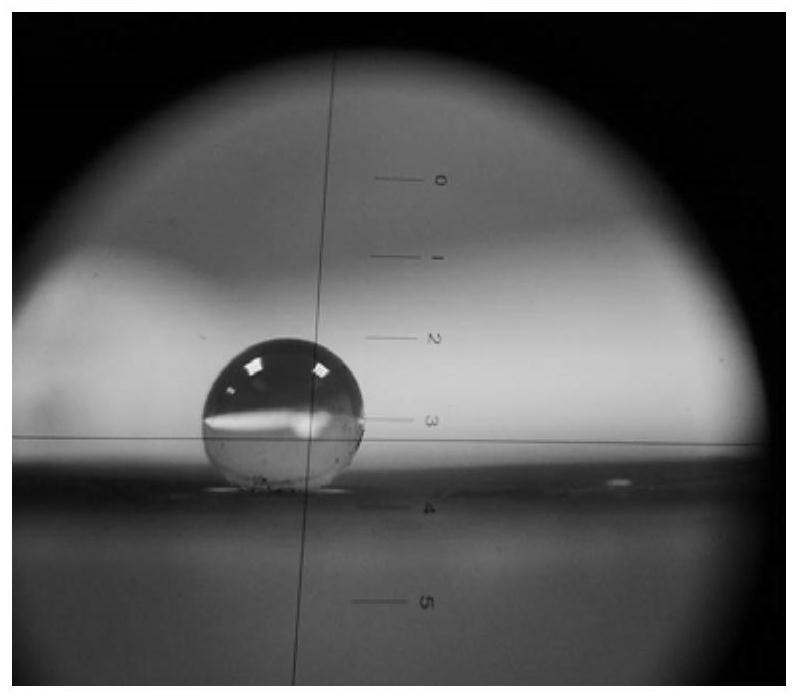

A technology of super-hydrophobic surface and substrate surface, which can be used in the fields of waterproof, stretchable devices, and self-cleaning, and can solve the problems of high price, unenvironmental protection, and unsuitable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of a stretchable superhydrophobic surface material:

[0035] (1) Mix the body of polydimethylsiloxane silica gel and the crosslinking agent together at a mass ratio of 10:1 to obtain polydimethylsiloxane silica gel prepolymer, and then coat 2g of the prepolymer Apply evenly on the outer surface of the plastic culture dish (round shape, 90mm in diameter) to obtain an uncured polydimethylsiloxane coating;

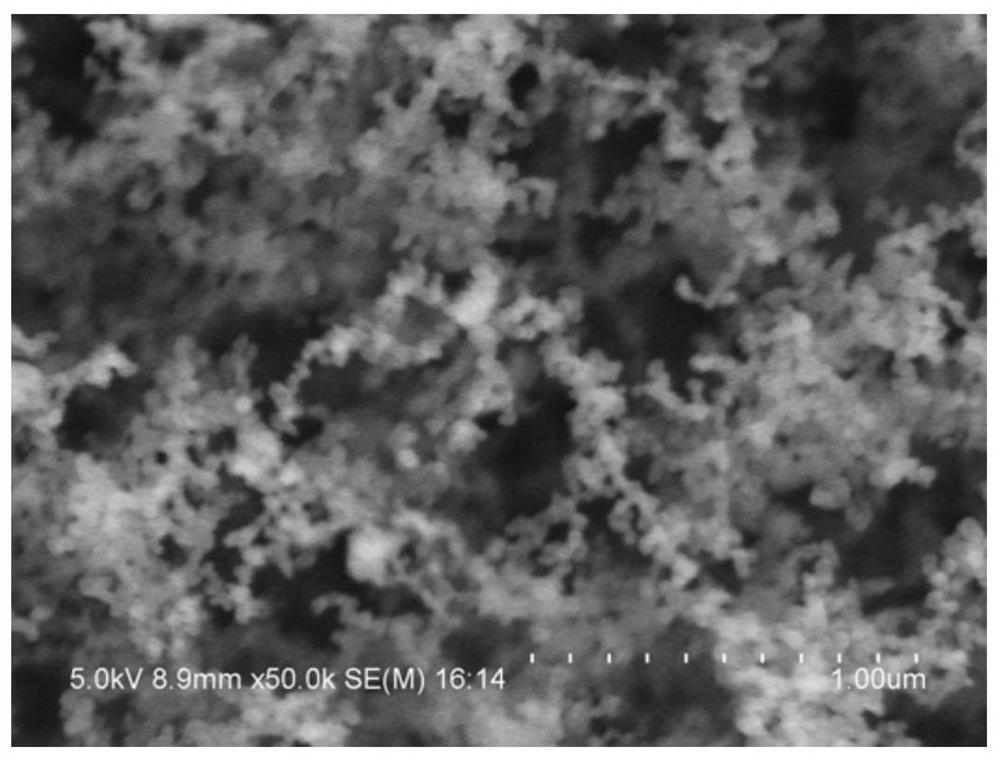

[0036] (2) Baking on the candle flame to obtain the candle soot layer: place the plastic Petri dish coated with uncured polydimethylsiloxane silica gel above the candle flame, so that the uncured polydimethylsiloxane The alkane coating is close to the flame side of the candle and covers 1 / 3-1 / 2 of the flame height when the candle is naturally burning. Move the plastic petri dish coated with polydimethylsiloxane to make the polydimethylsiloxane The surface of the coating is uniformly covered with candle soot until the thickness of the candle soot layer is 2...

Embodiment 2

[0039] Preparation of a stretchable superhydrophobic surface material:

[0040] (1) liquid nitrile rubber can be used directly, 0.5g liquid nitrile rubber is evenly coated on the glass surface (rectangular, 25mm*75mm), obtains uncured nitrile rubber coating;

[0041] (2) Baking on the candle flame to obtain the candle ash layer: place the glass piece coated with uncured nitrile rubber coating above the candle flame, make the uncured nitrile rubber coating close to the side of the candle flame and cover 1 / 3-1 / 2 of the flame height when the candle burns naturally, move the glass sheet coated with nitrile rubber to make the surface of the nitrile rubber coating evenly covered with candle soot, the thickness of the candle soot layer is 5μm, D The nitrile rubber coating will cure under the heat of the candle flame to form a nitrile rubber film;

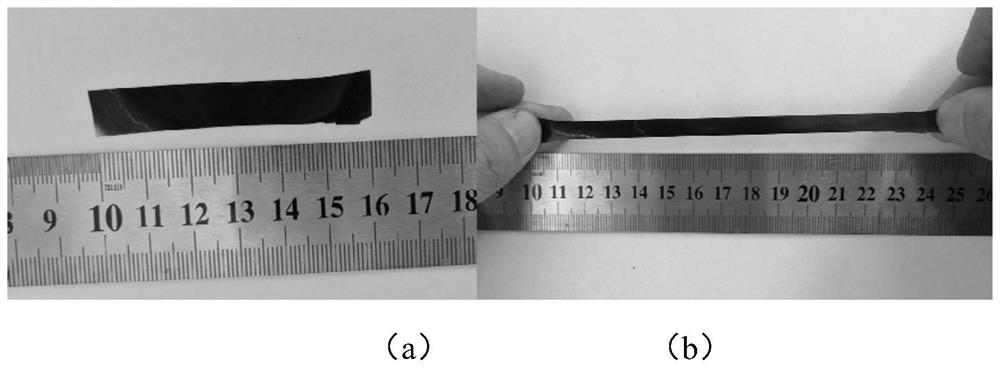

[0042] (3) The nitrile rubber film with candle soot attached to the surface is peeled off from the glass sheet to obtain a stretchable s...

Embodiment 3

[0044] Preparation of a stretchable superhydrophobic surface material:

[0045] (1) The body of the liquid isoprene rubber and the crosslinking agent are combined in a mass ratio of 100:3 to obtain the isoprene rubber prepolymer, and 0.5 g of the prepolymer is evenly coated on the surface of the glass sheet (rectangular , 25mm*75mm), to obtain uncured isoprene rubber coating;

[0046] (2) Bake the candle soot layer on the candle flame: place the glass piece coated with uncured isoprene rubber coating above the candle flame, make the uncured isoprene rubber coating close to the side of the candle flame and cover it. 1 / 3-1 / 2 of the flame height when the candle burns naturally, move the glass sheet coated with isoprene rubber to make the surface of the mixed prepolymer evenly covered with candle soot, the thickness of the candle soot layer is 10μm, isoprene rubber The coating will cure under the heat of a candle flame to form a film of isoprene rubber;

[0047] (3) The isoprene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com