High-viscosity thin-layer bituminous mixture modifier and application thereof

An asphalt mixture and modifier technology, which is used in building thermal insulation materials, coagulative pavement paved on site, building components, etc. Time reduction and other problems, to achieve the effect of compact construction process connection, dense roughness and no water seepage, high construction quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

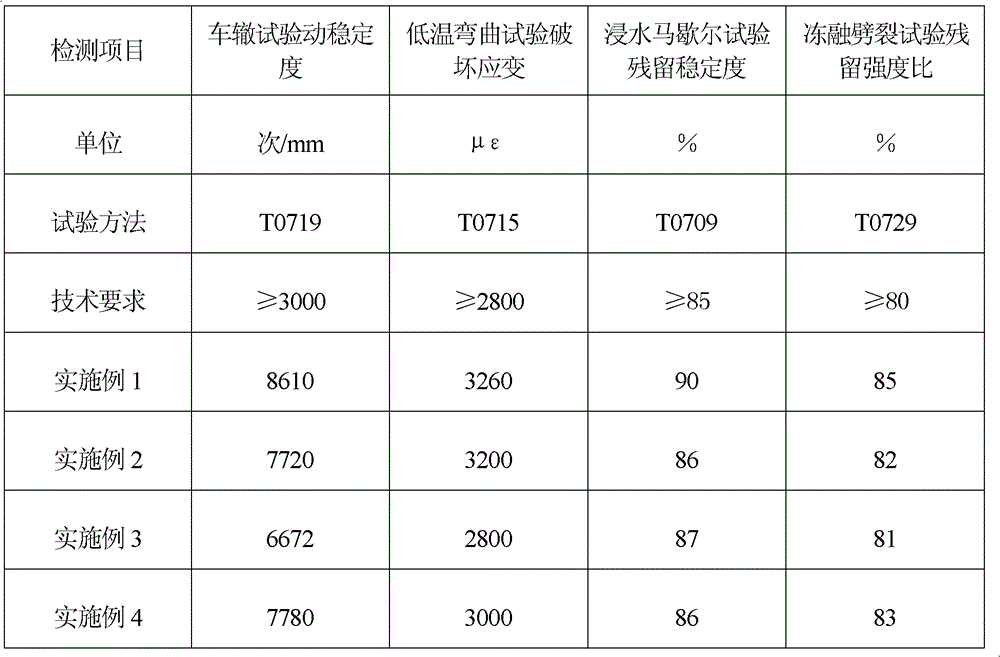

Examples

Embodiment 1

[0042] 1) Prepare high-viscosity thin-layer asphalt mixture modifier, take the preparation of 100kg modifier as an example:

[0043] Weigh 60kg of polyethylene, 6kg of commercially available GW-1401 tackifying resin, 12kg of rock asphalt, 2kg of PE color masterbatch, and 20kg of pottery clay. 170°C, through a screw extruder, prepare a strip-shaped mixture, cool it to room temperature with water, and use a cutting machine to cut the strip-shaped mixture into flake-shaped particles to obtain a high-viscosity thin-layer asphalt mixture modifier;

[0044] The above-mentioned pottery clay can be replaced by fly ash, or mixed with talc and mica powder;

[0045]2) Preparation of high-viscosity thin-layer asphalt mixture: by weight, the aggregate composition is 58% of 6-11mm stone, 12% of 4-6mm stone, 22% of 0-4mm stone, and 8% of mineral powder; 5.8% asphalt; when mixing, the aggregate heating temperature is 175°C, and the asphalt heating temperature is 155°C; the high-viscosity thi...

Embodiment 2

[0051] Weigh 10kg of polyethylene, 40kg of recycled polyethylene, 2kg of GW-1402 tackifying resin, 10kg of lake asphalt, 1kg of PE color masterbatch, and 37kg of talc. Mix and stir all components evenly and add them to the hopper of the screw extruder, heat To 180°C, the strip mixture is prepared by a screw extruder, cooled to normal temperature by water, and the strip mixture is cut into sheet-shaped particles by a cutting machine to obtain a high-viscosity thin-layer asphalt mixture modifier.

[0052] The above-mentioned GW-1402 tackifying resin can be replaced by GW-1401 tackifying resin or GW-1403 tackifying resin, and can also be replaced by mixing GW-1401 tackifying resin and GW-1403 tackifying resin.

[0053] The process of preparing high-viscosity thin-layer asphalt mixture with the modifying agent of this example is basically the same as embodiment 1, but wherein the high-viscosity thin-layer asphalt mixture modifier accounts for 0.3% of aggregate, mineral powder and a...

Embodiment 3

[0056] Weigh 56kg of polyethylene, 14kg of polyolefin wax, 8kg of GW-1403 tackifying resin, 7kg of rock asphalt, 8kg of lake asphalt, 3kg of PE color masterbatch, and 4kg of silica. After mixing the components evenly, add them to the screw In the hopper of the extruder, heat it to 150°C to prepare a strip mixture, cool it to normal temperature with water, and use a cutting machine to cut the strip mixture into granular particles to obtain a high-viscosity thin-layer asphalt mixture modifier.

[0057] Above-mentioned silicon dioxide can also be replaced by mixing talcum and powdered cellulose;

[0058] The process of preparing the high-viscosity thin layer asphalt mixture with the modifier of this example is the same as that of Example 1.

[0059] The milling depth is 1.5 cm when repairing the road surface with the high-viscosity thin-layer asphalt mixture prepared by the modifier of this example, and the rest of the process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com