Rough surface for fractal structure

A fractal structure and rough surface technology, which is applied in the field of functional structural elements for flow drag reduction, can solve problems such as inability to achieve super-hydrophobicity, and achieve the effect of efficient flow drag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Carry out further detailed description below in conjunction with accompanying drawing:

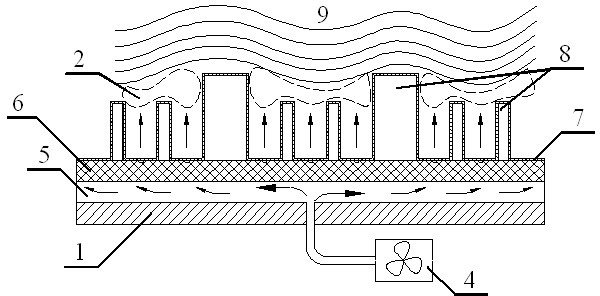

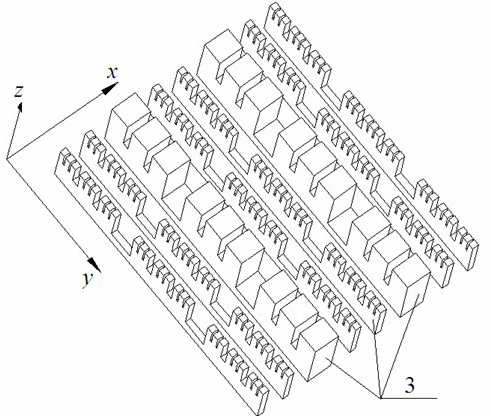

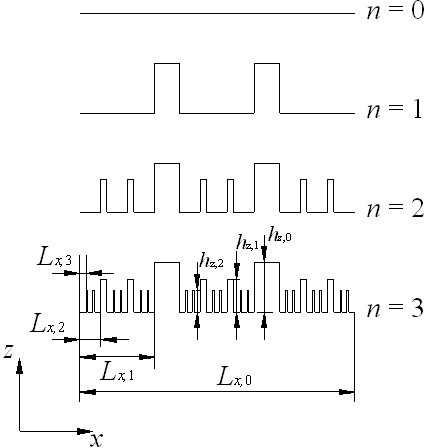

[0018] figure 1 A schematic diagram of a fractal structure rough surface is given. A fractal structure rough surface is composed of a substrate 1 , a noncondensable gas film layer 2 and a rough structure 3 . The non-condensable gas film layer 2 is composed of a compressed gas generator 4 , a gas containing chamber 5 and a porous core 6 . The porous core 6 is disposed on the surface of the substrate 1 through the connecting piece 7 , and the gap between the substrate 1 and the porous core 6 forms a gas containing chamber 5 . The roughness 3 is arranged on the surface of the porous core 6 . Both the outer surface of the porous core 6 and the outer surface of the rough structure 3 are coated with a low surface energy substance 7 to improve surface hydrophobicity. The rough structure is a series of micro-rib structures 8 with fractal characteristics in rough distribution to form a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com