High-adhesion quasi-super-hydrophobic material and preparation method thereof

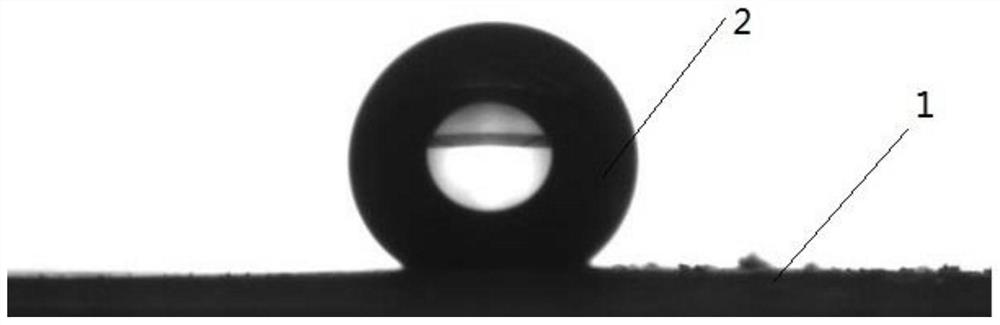

A high-adhesion, super-hydrophobic technology, applied in paper coating, water repellent addition, fiber raw material treatment, etc., can solve the problems of complex process and harmful environment, and achieve the effect of simple preparation method and increased contact angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

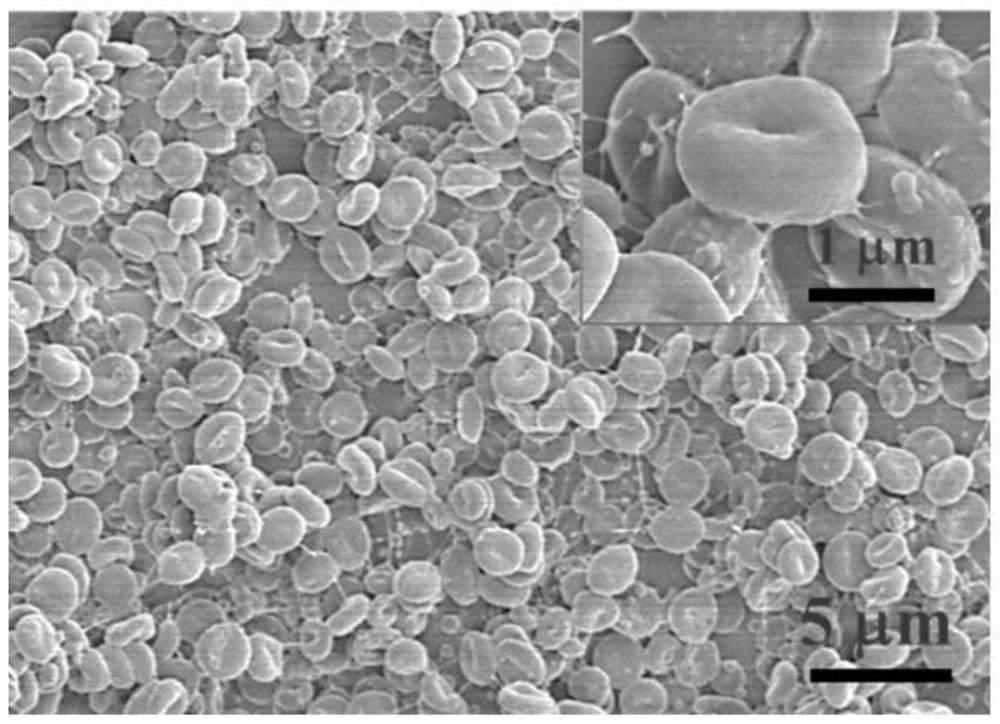

[0044] At 20-25°C, weigh 0.68g of polyurethane and dissolve it in 20g of N,N-dimethylformamide solvent, and stir for 12h with a magnetic stirrer to obtain a uniform and transparent electrospray solution.

[0045] Using an electrostatic spraying device, the electrospray solution is electrostatically sprayed onto the surface of the silicone oil paper on the flat receiving device, so that polyurethane microspheres are attached to the surface of the silicone oil paper substrate, thereby obtaining a highly adhesive quasi-superhydrophobic material. Among them, the parameters of the electrostatic spray are set as follows: needle inner diameter 0.34mm, voltage 20kV, advancing speed 0.8mL / h, advancing volume 1.2mL, temperature 25°C, relative humidity 65%, the distance between the flat receiving device and the needle (receiving distance) is 15cm , the receiving surface of the flat receiving device is covered with silicone oil paper.

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 lies in that the amount of polyurethane is different, and the voltage and propulsion speed of electrostatic spraying are different. in particular:

[0048]At 20-25°C, weigh 0.48g of polyurethane and dissolve it in 20g of N,N-dimethylformamide solvent, and stir for 12h with a magnetic stirrer to obtain a uniform and transparent electrospray solution.

[0049] Using an electrostatic spraying device, the above-mentioned electrospray solution is electrostatically sprayed onto the surface of the silicone oil paper on the flat receiving device, so that polyurethane microspheres are attached to the surface of the silicone oil paper substrate, thereby obtaining a high-adhesion quasi-superhydrophobic material. Among them, the parameters of the electrostatic spray are set as follows: needle inner diameter 0.34mm, voltage 16kV, advancing speed 0.4mL / h, advancing volume 1.2mL, temperature 25°C, relative humidity 65%, the dista...

PUM

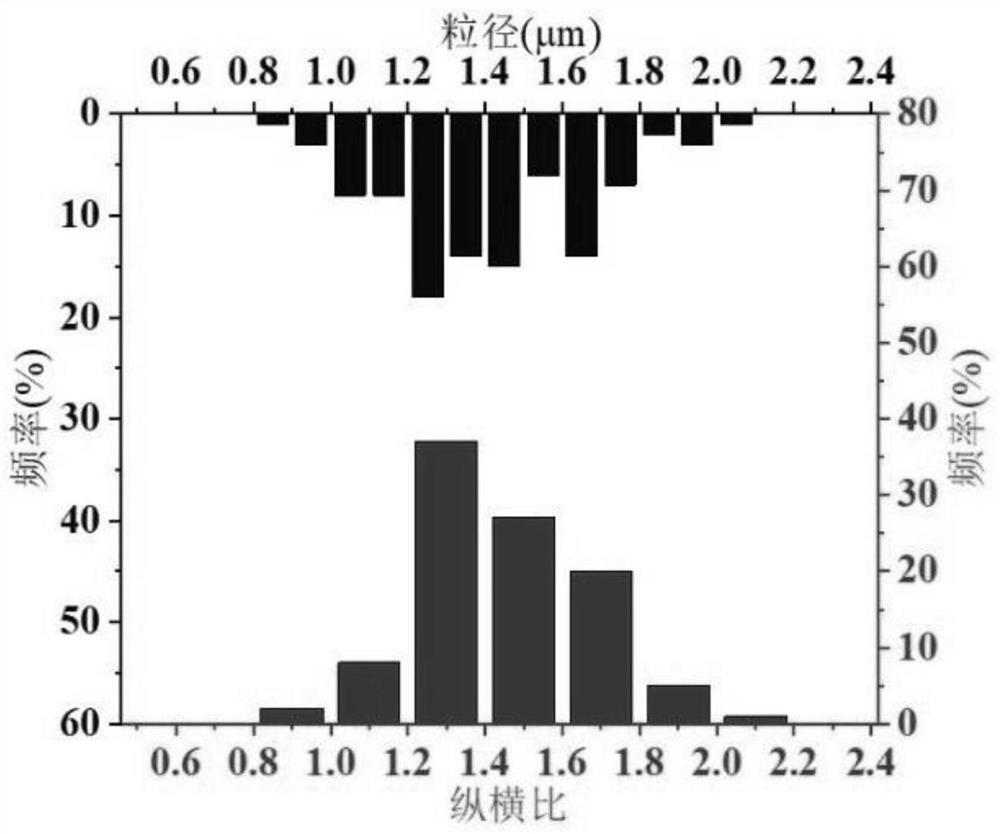

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com