Preparation method of super-hydrophobic PVDF (polyvinylidene fluoride) membrane with micro-nano structure

A microstructure and super-hydrophobic technology, which is applied in the field of super-hydrophobic PVDF membrane preparation, can solve the problems such as the decline of system operation effect, achieve the effect of improving anti-wetting performance, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

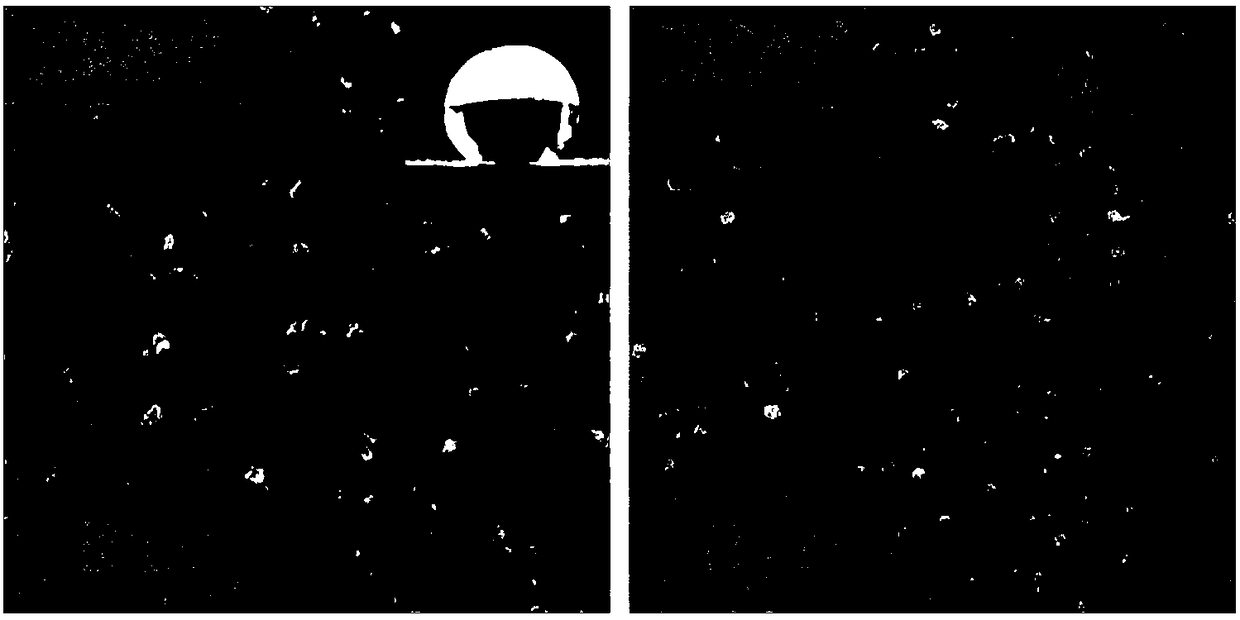

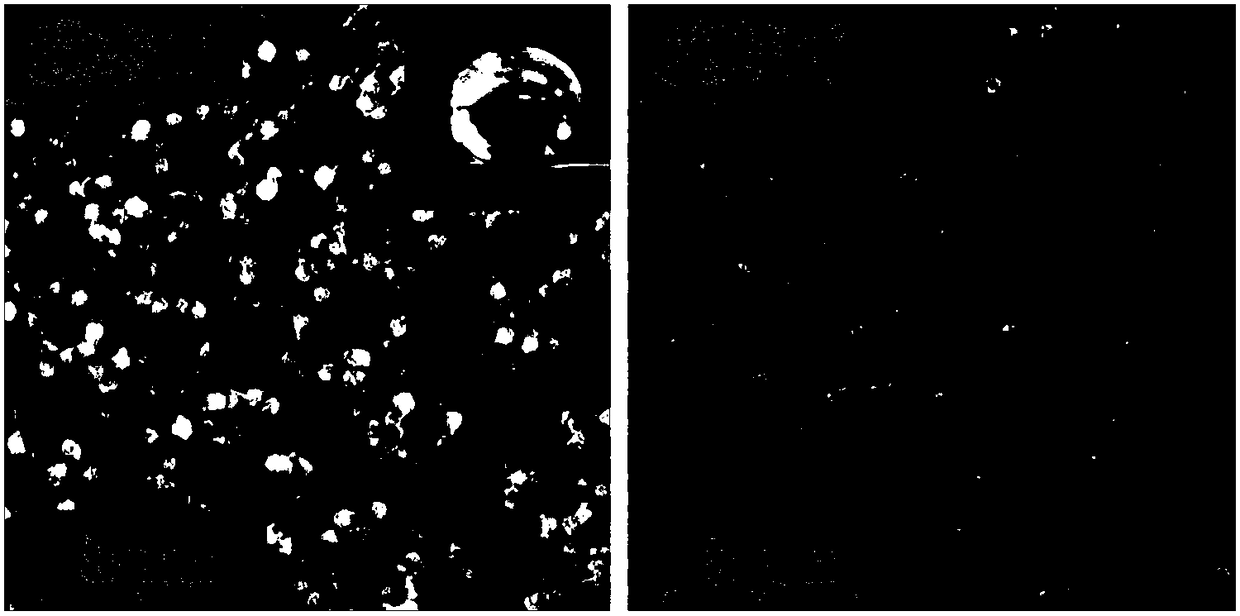

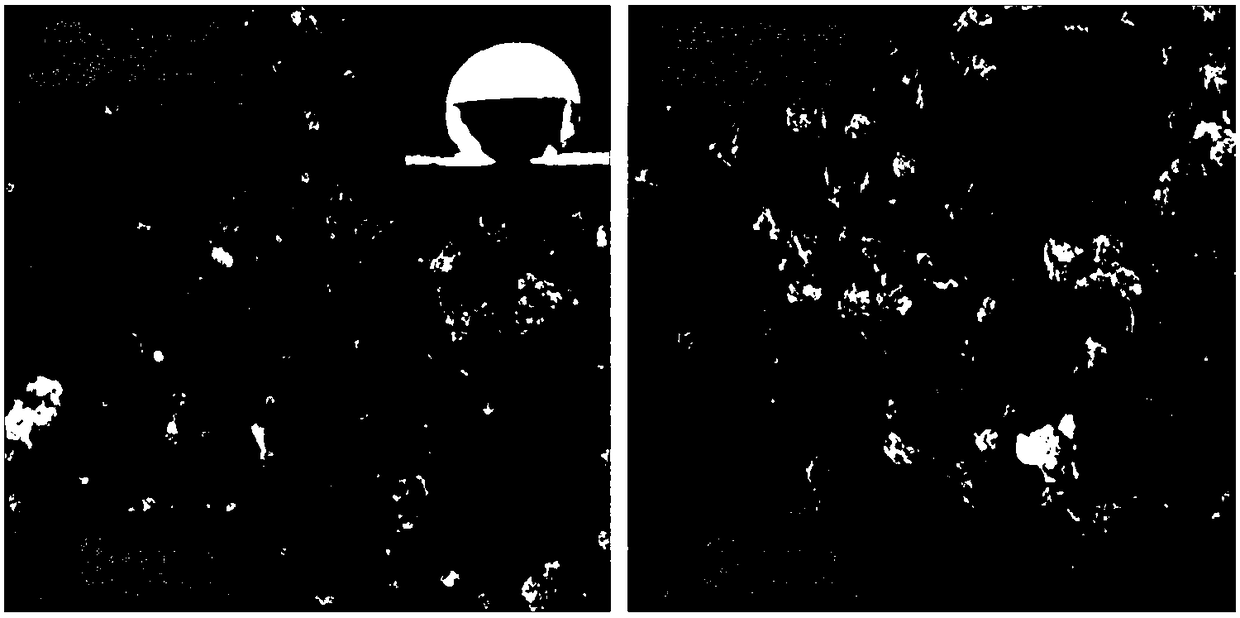

Image

Examples

Embodiment 1

[0024] A preparation method of superhydrophobic PVDF membrane with micro-nano double microstructure, including the following steps:

[0025] (1) Configure casting solution: 1.7g of dried TiO 2 The nanoparticles were put into 73mL of N-methylpyrrolidone, 0.86mL of PEG-400 was added, and stirred to make TiO 2 Disperse the nanoparticles to obtain a suspension, put 17g of dry PVDF (polyvinylidene fluoride) powder into the suspension, stir in a 60°C constant temperature water bath for 12 hours to make it uniform, and stand for 12 hours to defoam to obtain a casting liquid;

[0026] (2) Put the casting liquid obtained in step (1) on a glass support plate and scrape it with a film scraper to make a nascent flat film with a thickness of about 200μm. It will stay in the air at 28°C and a relative humidity of 60% for 60s. Into a methanol aqueous solution with a volume concentration of 75% to complete the phase inversion; wash with tap water, soak in tap water for 72 hours, replace the tap wat...

Embodiment 2

[0029] A preparation method of superhydrophobic PVDF membrane with micro-nano double microstructure, including the following steps:

[0030] (1) Configure casting liquid: 1.95g dried SiO 2 The nanoparticles were put into 81mL of N,N-dimethylformamide, 4.3mL of PEG-600 was added, and stirred to make SiO 2 Disperse the nanoparticles to obtain a suspension, put 13g of dry PVDF powder into the suspension, stir for 8h in a constant temperature water bath at 70°C for 8h, and let stand for 8h to defoam to obtain a casting liquid;

[0031] (2) Place the casting liquid obtained in step (1) on a glass support plate and scrape it with a film scraper to produce a nascent flat film with a thickness of about 200 μm. Leave it in the air at 30°C and a relative humidity of 70% for 30 seconds. Into the ethanol aqueous solution with a volume concentration of 95% to complete the phase inversion; wash with tap water, soak in tap water for 72 hours, replace the tap water every 12 hours during the period,...

Embodiment 3

[0034] A preparation method of superhydrophobic PVDF membrane with micro-nano double microstructure, including the following steps:

[0035] (1) Configure casting solution: 0.5g dried TiO 2 The nanoparticles were put into 75mL N,N-dimethylformamide, 1mL PVP was added, and stirred to make TiO 2 Disperse the nanoparticles to obtain a suspension, put 10g of dry PVDF powder into the suspension, stir in a 60°C constant temperature water bath for 12 hours for uniformity, and stand for 12 hours to defoam to obtain a casting liquid;

[0036] (2) Place the casting liquid obtained in step (1) on a glass support plate and scrape a nascent flat film with a thickness of about 200 μm with a film scraper, and stay in the air at 25°C and 40% relative humidity for 60 seconds, Into a 50% volume concentration of n-propanol (isopropanol) aqueous solution to complete the phase conversion; wash with tap water, soak in tap water for 24 hours, during which time the tap water is replaced every 12 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com