Novel micro-nano structure surface anti-deicing skin

A micro-nano structure and a new type of technology, used in deicing devices, aircraft parts, transportation and packaging, etc., to achieve the effects of improved service life, easy application and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

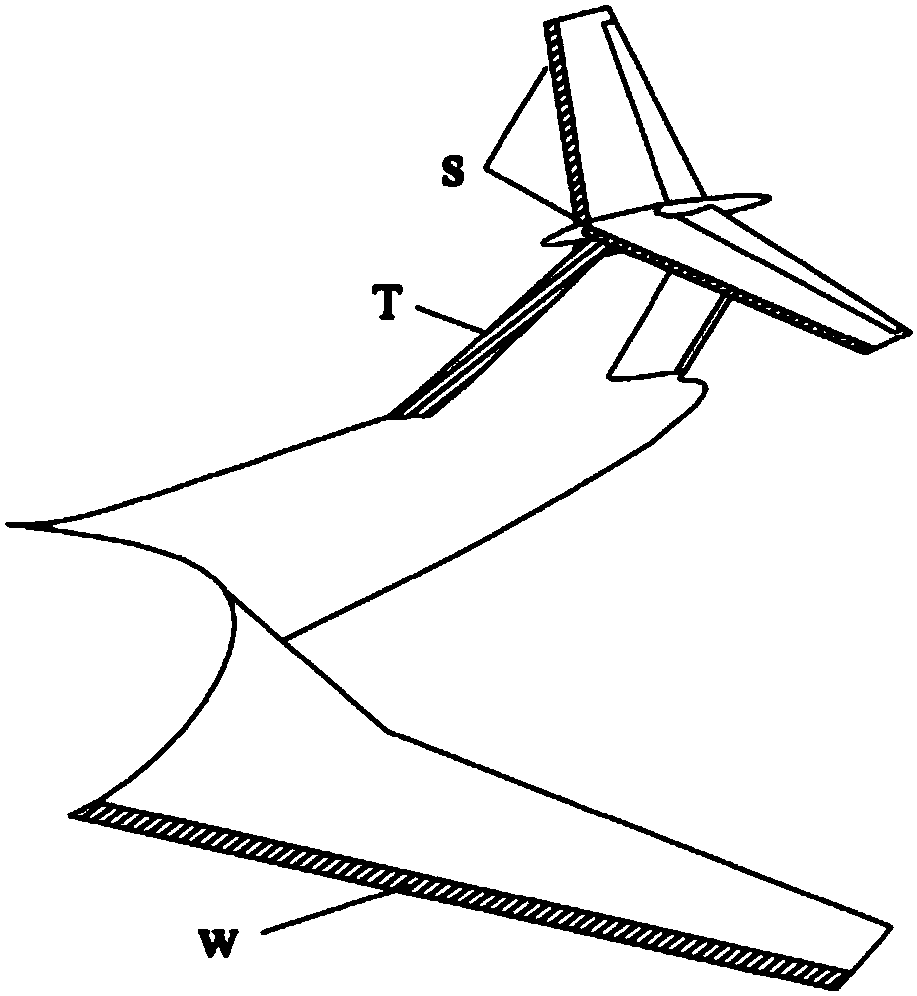

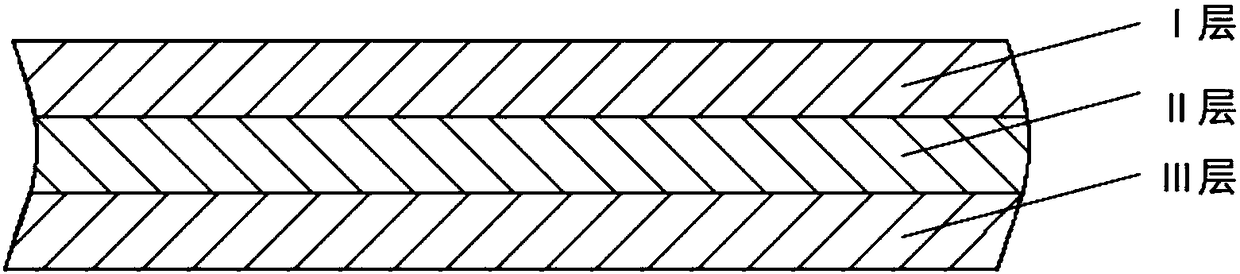

[0021] like figure 2 As shown, a flexible new micro-nano structure surface anti-icing skin, including a multi-layer composite structure.

[0022] Among them, layer I is the superhydrophobic layer on the surface, which is obtained by coating the superhydrophobic film. The surface superhydrophobic layer is obtained by modifying low surface energy substances on the surface of the constructed micro-nano structure. In this embodiment, the surface modification low surface energy substance is perfluorobutyric acid. In this embodiment, polyimide etching technology is used to form a microstructure on the polyimide film, and then plasma nano-deposition technology is used to reduce the surface energy of the material, thereby achieving superhydrophobic performance. The basic requirements for hydrophobic performance design are: the contact angle is greater than 145°, and the contact angle hysteresis is less than 10°. The basic requirements for compatibility with the electric heating la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com