Anti-condensation coating, radiation terminal with anti-condensation coating on surface, radiator and air-conditioning system

An anti-condensation and coating technology, which is used in air-conditioning systems, conductive coatings, and prevention of condensed water, etc., can solve the problems of poor heating experience, complex structure of refrigeration systems, and easy condensation on the surface of cold and hot radiant panels, and achieve improved stability. performance and longevity, simplified subsequent operation process, good anti-condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the anti-condensation coating comprises the steps:

[0044] (1) Preparation of graphene-coated particle mixture:

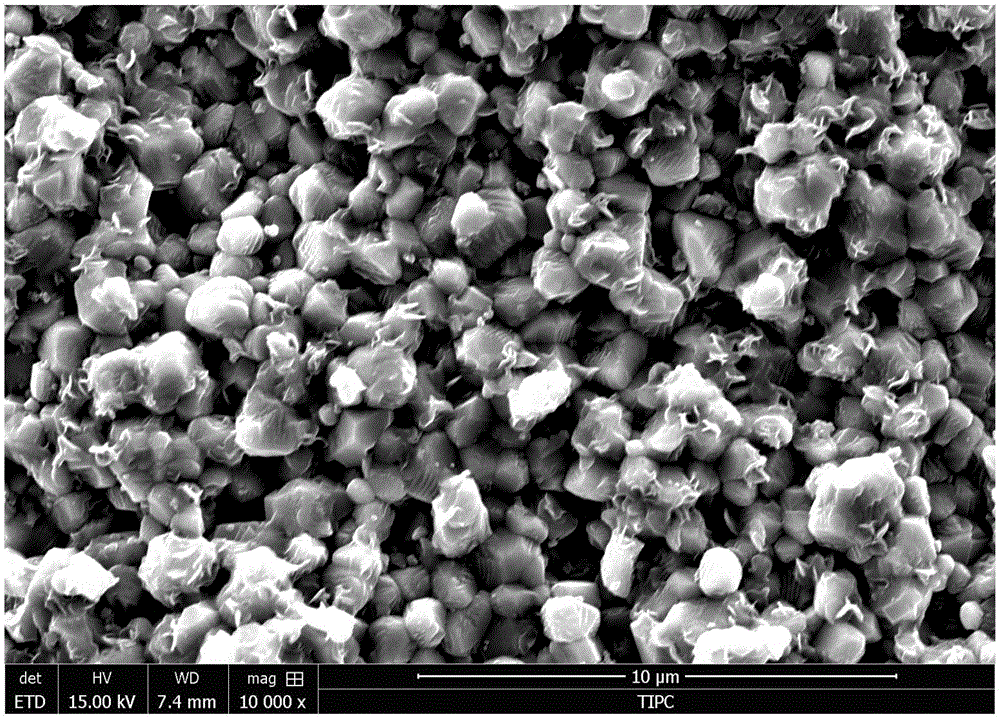

[0045] 85-99 wt. % of a particle mixture with a particle size of 0.2-5 μm (in which the volume ratio of inorganic particles to organic particles is 1:2), 0.5-10 wt. % of graphene and 0.5-5 wt. % of dispersant are added to Mixing thoroughly in absolute ethanol by wet ball milling for 2-12 hours to coat the surface of the particles with flake graphene; then fully drying and passing through a 500-mesh sieve; obtaining a graphene-coated particle mixture; the graphene-coated A typical SEM photo of a particle mixture such as figure 1 As shown, it can be observed that a layer of thin-film graphene is coated on the surface of the particle;

[0046] (2) Preparation of anti-condensation coating:

[0047] Under certain temperature and / or atmosphere protection conditions, 40-79% of superhydrophobic raw material, 1-10% of graphene and 20-50%...

Embodiment 1

[0049] (1) 90wt.% of PTFE powder with an average particle size of 500nm and TiO 2 The particle mixture (volume ratio of 2:1) was added to anhydrous ethanol solvent with 5wt.% graphene and 5wt.% PEG-400, followed by ball milling for 4 hours; the ball-milled slurry was placed in an oven at 60 °C to dry 8 hours, followed by grinding and sifting through a 500 mesh screen; a graphene-coated Teflon / titanium dioxide particle mixture was obtained.

[0050] (2) 40wt.% of the graphene-coated polytetrafluoroethylene / titanium dioxide particle mixture, 10% of graphene and 50wt.% of perfluorooctadecyltrichlorosilane were dissolved in n-hexane and thoroughly mixed; Condensation paint.

[0051] After the coating is sprayed and dried, the contact angle of the coating to water can reach 150°, and it can heat up to 38°C when connected to a voltage of 24V.

Embodiment 2

[0053] (1) 95wt.% of polyvinylidene fluoride / Al having an average particle size of 1 μm 2 O 3 The particle mixture (volume ratio of 2:1) was added to anhydrous ethanol solvent with 3wt.% graphene and 2wt.% PEG-400, followed by ball milling for 8 hours; the slurry after ball milling was placed in a 60°C oven to dry 8 hours, followed by grinding and sieving through a 500 mesh screen; a graphene-coated polyvinylidene fluoride / alumina particle mixture was obtained.

[0054] (2) 30wt.% of the graphene-coated polyvinylidene fluoride / alumina particle mixture, 5% of graphene and 65% of perfluoropolymethacrylate were dissolved in trifluorotrichloroethane and thoroughly mixed ; Obtain anti-condensation paint.

[0055] After the coating is sprayed and dried, the contact angle of the coating to water can reach 157°, and it can heat up to 25°C when connected to a 24V voltage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com