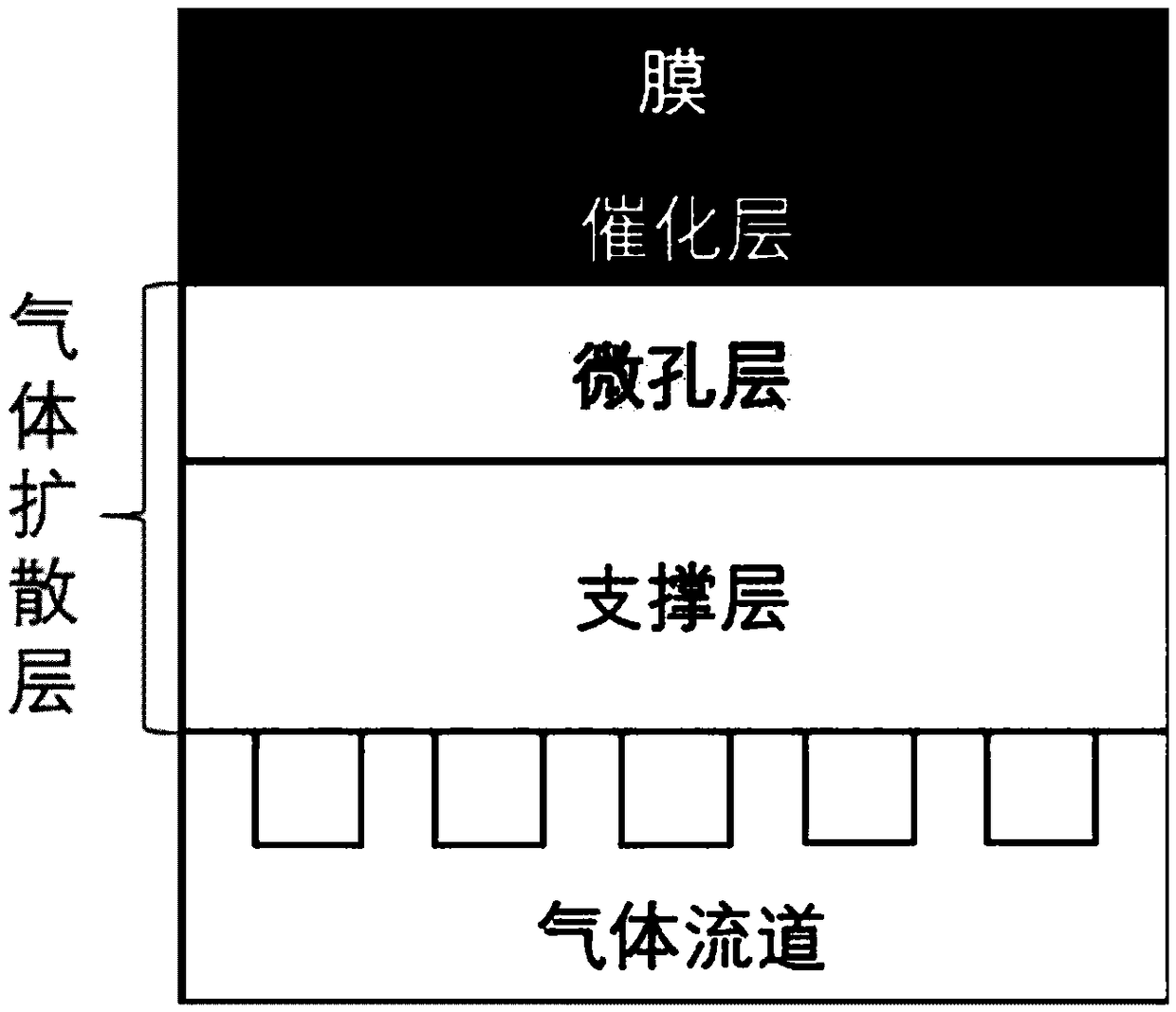

A microporous layer of a gas diffusion layer of a proton exchange membrane fuel cell and a preparation method thereof

A gas diffusion layer and proton exchange membrane technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of high heat treatment temperature and complicated treatment process, and achieve the effects of improving roughness, environmental friendliness, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

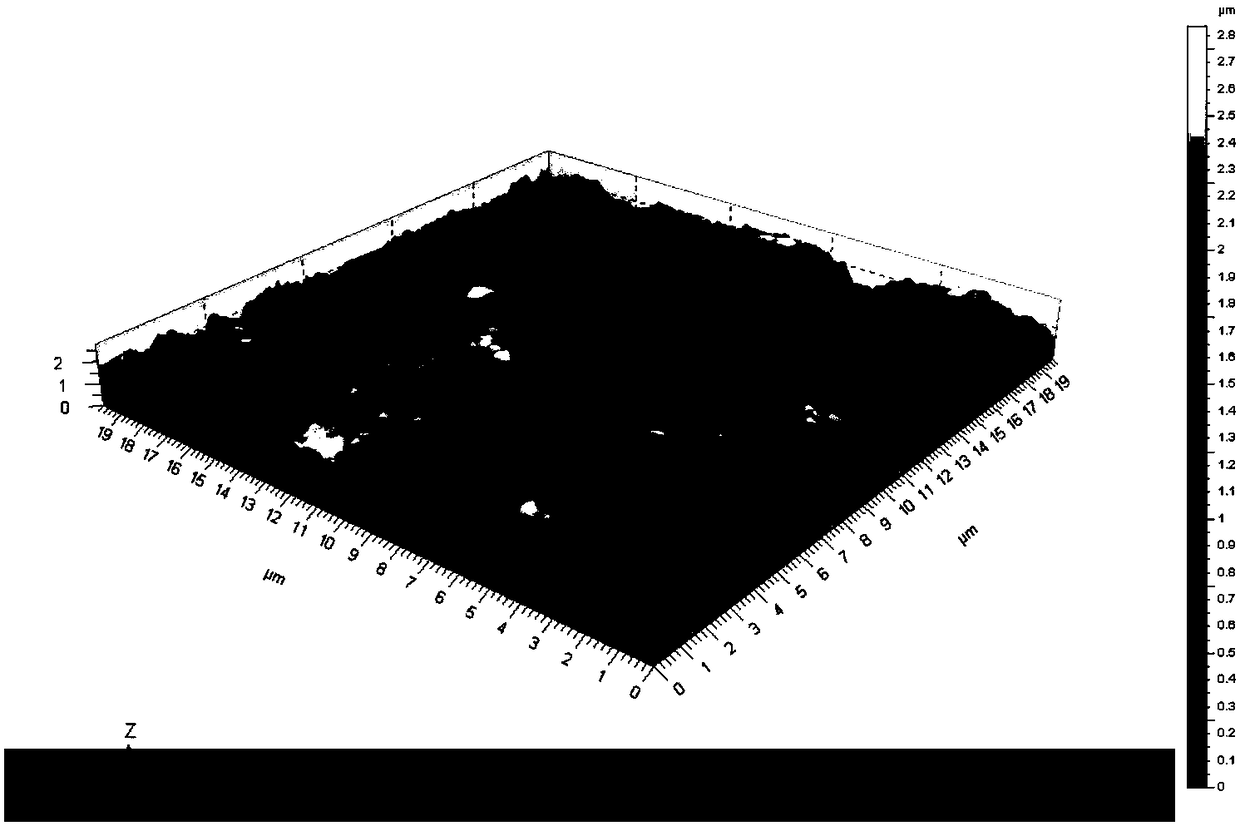

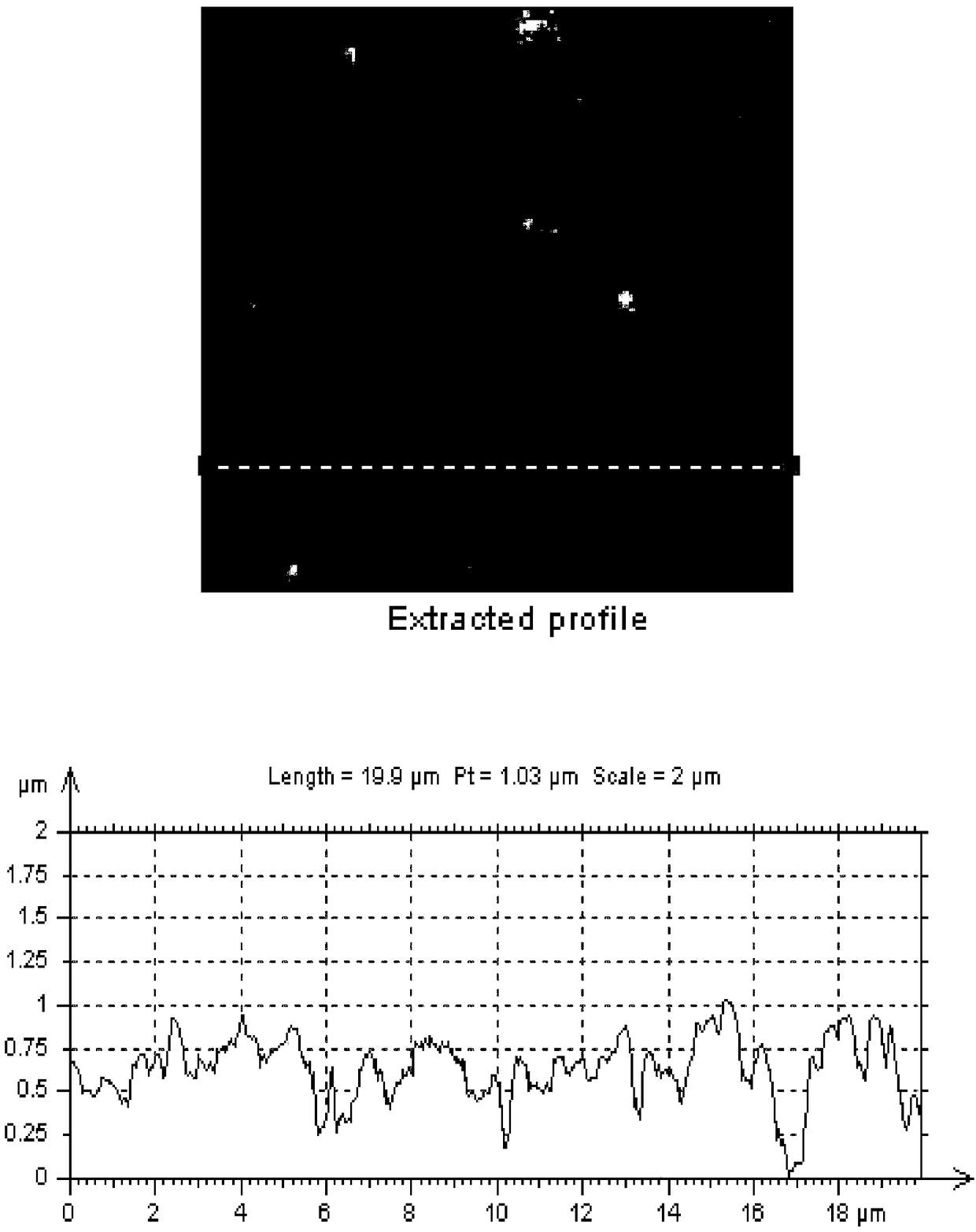

[0042] Dissolve polydimethylsiloxane and carbon black in tetrahydrofuran in a ratio of 1:1, mechanically stir, and ultrasonically form a uniform suspension (the concentration of polydimethylsiloxane is 3wt%). One side of the carbon paper is scraped and coated with the suspension until the loading of carbon black is 0.5mg / cm 2 , dried naturally, placed in a drying oven, and sintered at 160°C for 10min, the contact angle of the obtained gas diffusion layer was 152° (see Figure 5b ).

Embodiment 2

[0044] Dissolve polydimethylsiloxane and carbon black in tetrahydrofuran in a ratio of 8:3, mechanically stir, and ultrasonically form a uniform suspension (the concentration of polydimethylsiloxane is 8wt%). One side of the carbon paper is scraped and coated with the suspension until the loading of carbon black is 0.5mg / cm 2 , dried naturally, placed in a drying oven, and sintered at 200°C for 20min, the contact angle of the obtained gas diffusion layer was 120.06°.

[0045]It can be seen from the above examples 1 and 2 that the content of polydimethylsiloxane has a certain proportion range. If it exceeds this optimum amount, the contact angle will gradually decrease instead, and the superhydrophobicity of the microporous layer cannot be realized.

Embodiment 3

[0047] Dissolve polydimethylsiloxane and carbon black in tetrahydrofuran in a ratio of 2:3, mechanically stir, and ultrasonically form a uniform suspension (the concentration of polydimethylsiloxane is 2wt%). One side of the carbon paper is scraped and coated with the suspension until the loading of carbon black is 0.5mg / cm 2 , dried naturally, placed in a drying oven, and sintered at 160°C for 20min, the contact angle of the obtained gas diffusion layer was 148°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com