Hollow fiber membrane contactor, air dehumidification system and air humidification system for air humidity control

A fiber membrane contactor and air humidity technology, which is applied in air conditioning systems, space heating and ventilation, chemical instruments and methods, etc., can solve problems such as low efficiency, improve efficiency, improve transfer efficiency, and improve comprehensive heat transfer factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

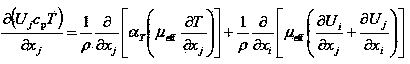

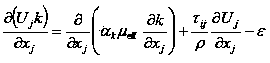

Method used

Image

Examples

Embodiment 1

[0024] A dehumidification system such as figure 1 with figure 2 As shown, including: a first induced draft fan 1, a first membrane contactor 2, a heater 3, a second induced draft fan 4, a second membrane contactor 5, a cooler 6, a liquid storage tank 7 and a solution pump 8, the The solution pump 8 pumps the dehumidification solution in the liquid storage tank 7 to the first membrane contactor 2, so that the dehumidification solution moves out and flows through the first membrane contactor 2, the heater 3, the second membrane contactor 5 and the cooler 6 After that, it flows back into the liquid storage tank 7; the first induced draft fan 1 makes the air to be dehumidified flow through the first membrane contactor 2 for dehumidification, and the second induced draft fan 4 makes the outside air flow through the second membrane contactor 5 to remove water vapor in the dehumidification solution, the first membrane contactor 2 and the second membrane contactor 5 both include a h...

Embodiment 2

[0093] A humidification system such as Figure 6 As shown, it includes an induced draft fan 11, a membrane contactor 12, a liquid storage tank 13, a solution pump 14 and a heater 15, and the solution pump 14 pumps the distilled water in the liquid storage tank 13 into the described heater 15, To make the distilled water return to the liquid storage tank 13 after passing through the heater 15 and the membrane contactor 12, when the air is humidified, the air is sent into the membrane contactor 12 by the induced draft fan 11; The distilled water is driven by the solution pump 14 and sent into the membrane contactor 12 . Air flows on the shell side of the membrane contactor 12 and flows through the tube bundle along (parallel to) the direction of the minor axis of the ellipse; the distilled water heated by the heater 15 flows in the membrane fiber tube. Under the action of the vapor pressure difference, the gas and liquid conduct indirect water vapor heat and mass exchange throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com