Method for preparing super-hydrophobic membrane for removing dissolved gas in water

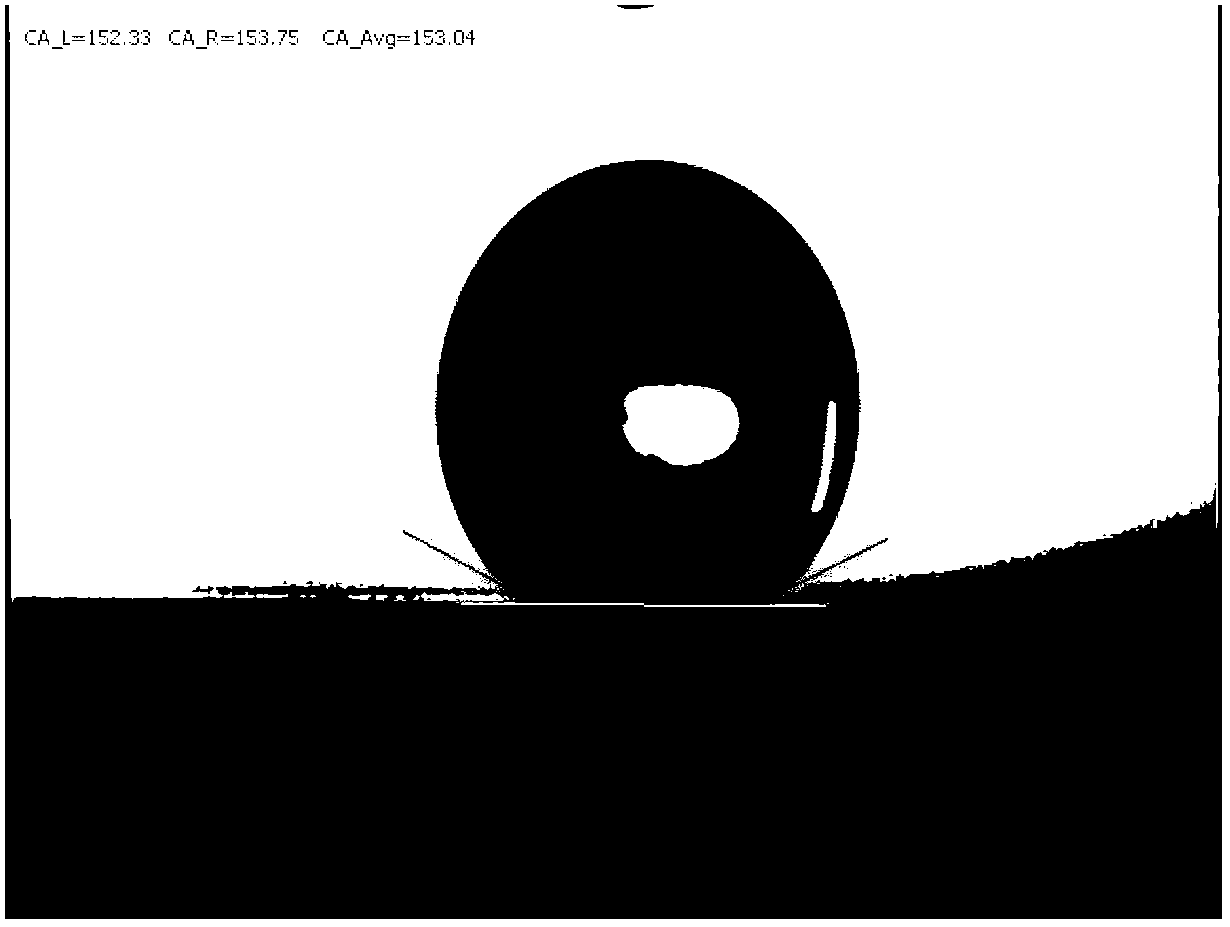

A super-hydrophobic and water-removing technology, applied in the chemical industry, can solve problems such as flux decline, achieve the effects of reducing mass transfer resistance, good super-hydrophobicity and self-cleaning performance, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

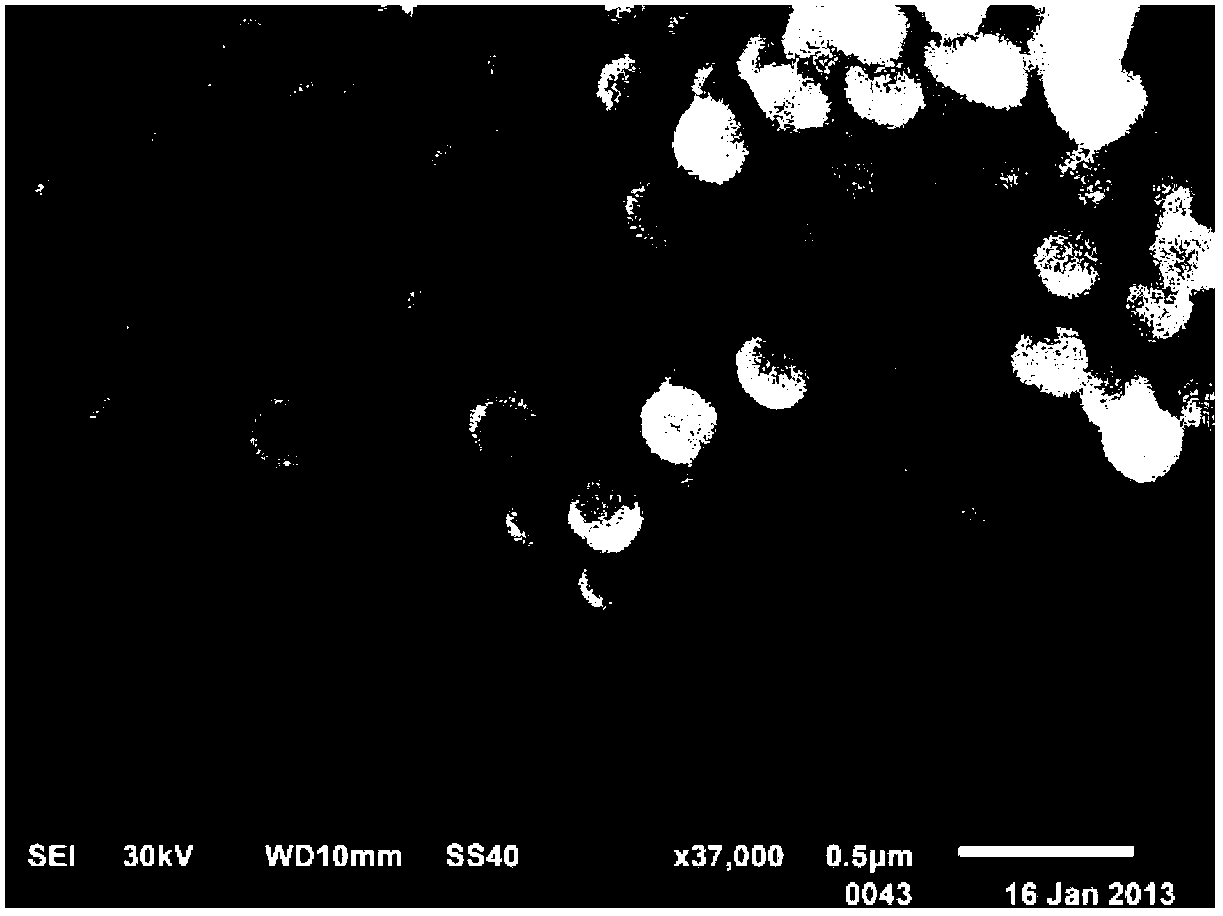

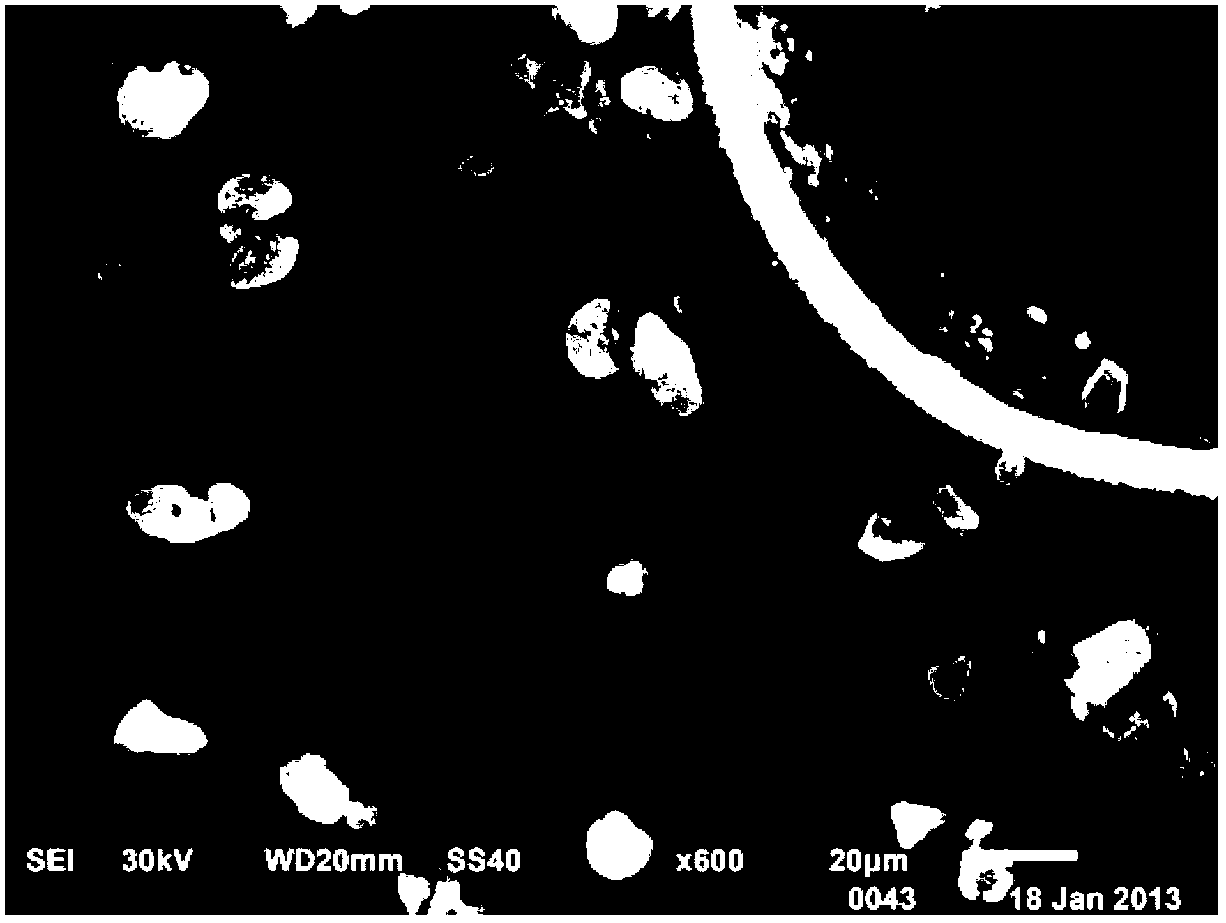

[0026] Add 7g of tetraethyl orthosilicate to 60ml of dispersant absolute ethanol, 2ml of hydrolysis catalyst ammonia and 2ml of deionized water, react at 30°C for 8h, and use the sol-gel method to prepare regular and uniform particles with a particle size of 140nm. of silica nanoparticles. Add 10 g of the alcohol solution containing silica nanoparticles dropwise to 1 g of the vinyltriethoxysilane coupling agent solution that has been catalytically hydrolyzed by ammonia water, stir for 2 hours, and carry out the reaction of the solution at a speed of 7000 r / min. After centrifugal separation, the obtained precipitate was placed in a vacuum oven at 60°C for 24 hours, then ground and sieved to obtain modified silica particles with a particle size of 10 μm. 5g of modified silicon dioxide micron particles and 10g of PVDF are added to 100ml of DMF solvent for dissolving, stirred in an oil bath at 50°C for 12h to obtain a film-making solution in which silicon dioxide particles are uni...

Embodiment 2

[0028] Add 7g of tetraethyl orthosilicate to 120ml of dispersant absolute ethanol, 5ml of hydrolysis catalyst ammonia and 5ml of deionized water, react at 30°C for 8h, and use the sol-gel method to prepare regular and uniform particles with a particle size of 50nm. of silica nanoparticles. Add 10 g of the alcohol solution containing silica nanoparticles dropwise to 2 g of the n-octylsilane coupling agent solution that has been catalytically hydrolyzed by ammonia water, stir for 2 hours, and centrifuge the reacted solution at a speed of 7000 r / min. The obtained precipitate was placed in a vacuum oven at 60° C. for 24 hours, then ground and sieved to obtain modified silica particles with a particle size of 3 μm. 10g of modified silicon dioxide micron particles and 10g of PVDF are added to 100ml of DMF solvent for dissolving, stirred in an oil bath at 50°C for 12h to obtain a film-making solution in which silicon dioxide particles are uniformly dispersed; the film-making solution...

Embodiment 3

[0030] Add 7g of tetraethyl orthosilicate to 120ml of dispersant absolute ethanol, 2ml of hydrolysis catalyst ammonia and 2ml of deionized water, react at 30°C for 8h, and use the sol-gel method to prepare regular and uniform particles with a particle size of 70nm. of silica nanoparticles. Add 10 g of the alcohol solution containing silica nanoparticles dropwise to 3 g of the n-octylsilane coupling agent solution catalyzed and hydrolyzed by ammonia water, stir for 2 hours, and centrifuge the reacted solution at a speed of 7000 r / min. After the obtained precipitate was placed in a vacuum oven at 60° C. for 24 hours, it was ground and sieved to obtain modified silica particles with a particle size of 6 μm. 10g of modified silicon dioxide micron particles and 15g of PVDF are added to 100ml of DMF solvent for dissolving, stirred in an oil bath at 50°C for 12h to obtain a film-making solution in which the silicon dioxide particles are evenly dispersed; the film-making solution is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com